Why lose time with interfaces?

Take it out of one hand!

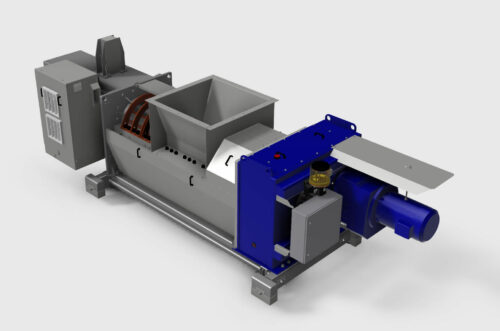

Meri has developed for more than 25 Years all Peripheral Subsystems around the Paper Production Process. WSR (Water, Sludge, Reject) Subsystems as well as the “Integrated Recycled Paper Mill Concept” have set new Standardsin Environmental Sustainability. Meri as a sole supplier can supply all Technologies as Material Handling, Fresh Water-Prep, Internal Water Management, Effluent Treatment, Reject and Residual Handling, Waste 2 Energy & more Out of on Hand with own proven Equipment.

Take care of your Paper Mill´s Health – Water Loop Management

25 and more Years ago fiber recovery and Save All applications have been purpose of water Treatment. Today advanced Water loop Management is not only key to “Lower Specific Water Consumption” but as well key for performance improvements as “Reduction of Stickies and Contaminants”, saving of chemicals and retention aids, ash and fines control, lower energy consumption and better run ability of the PM.

Water Loop Management follows technological principals but is always individual for each Paper Mill, we support You on your way to best Water Loop Management – Improve Your Sustainability.

The Difference:

Environmental Engineering by experts who understand the whole Paper Production Process

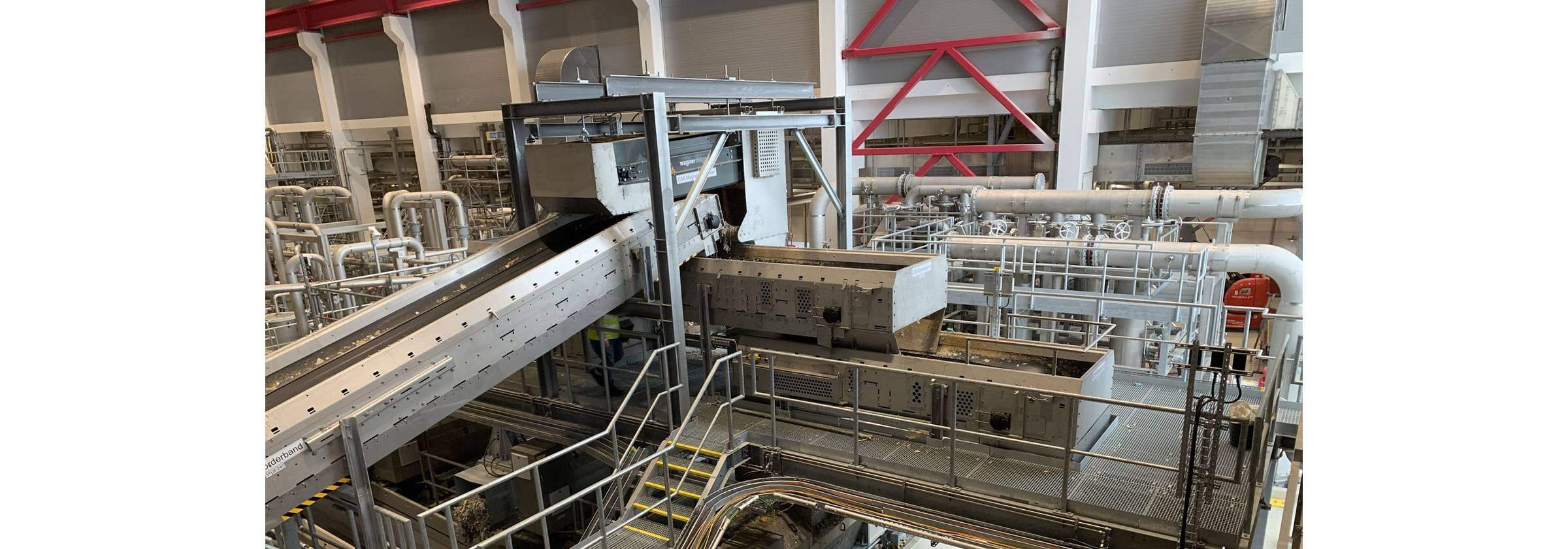

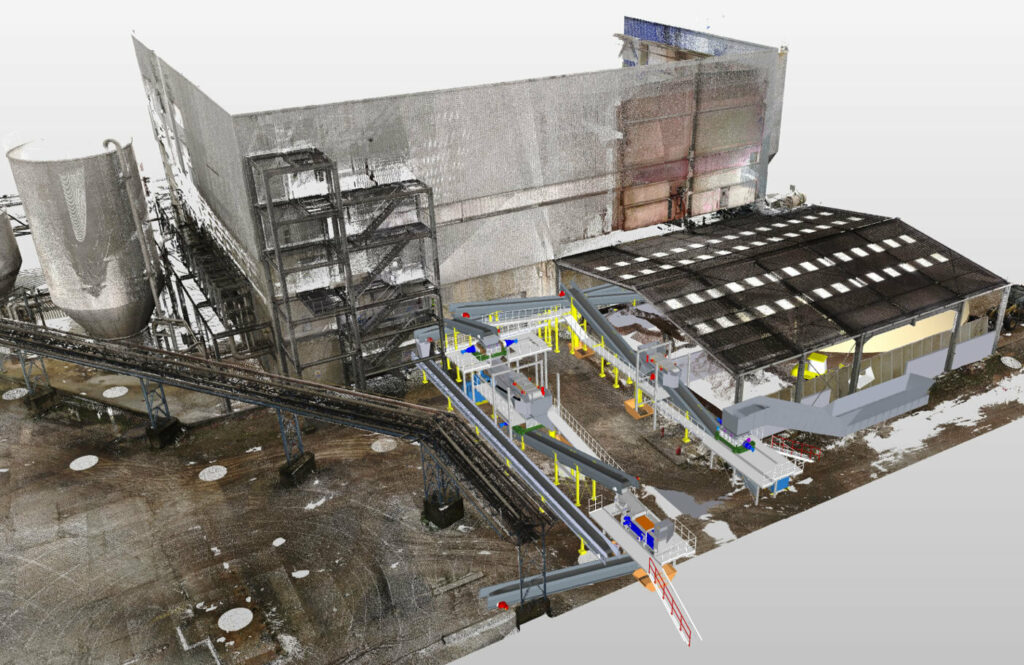

Process-, Production- and Environmental-Upgrades require a profound “Over All Paper Production Process Know How”. The meri Engineering Teams offer unique expertise, which goes beyond the interface and considers the production and peripheral processes as integrated mill. This allows us to elaborate for Your Mill integrated Process Upgrades, which secure synergies and gain in Productivity, better Environmental Interfaces, Improvement of Sustainability with Solutions and Equipment which was developed for the paper Industry.

Ask us for Engineering Services in the area of Process, Balancing, Simulation, E & Controls, 3D Laser Scanning and 3D Layouts, Audits all for Upgrade- and new Greenfield Projects.