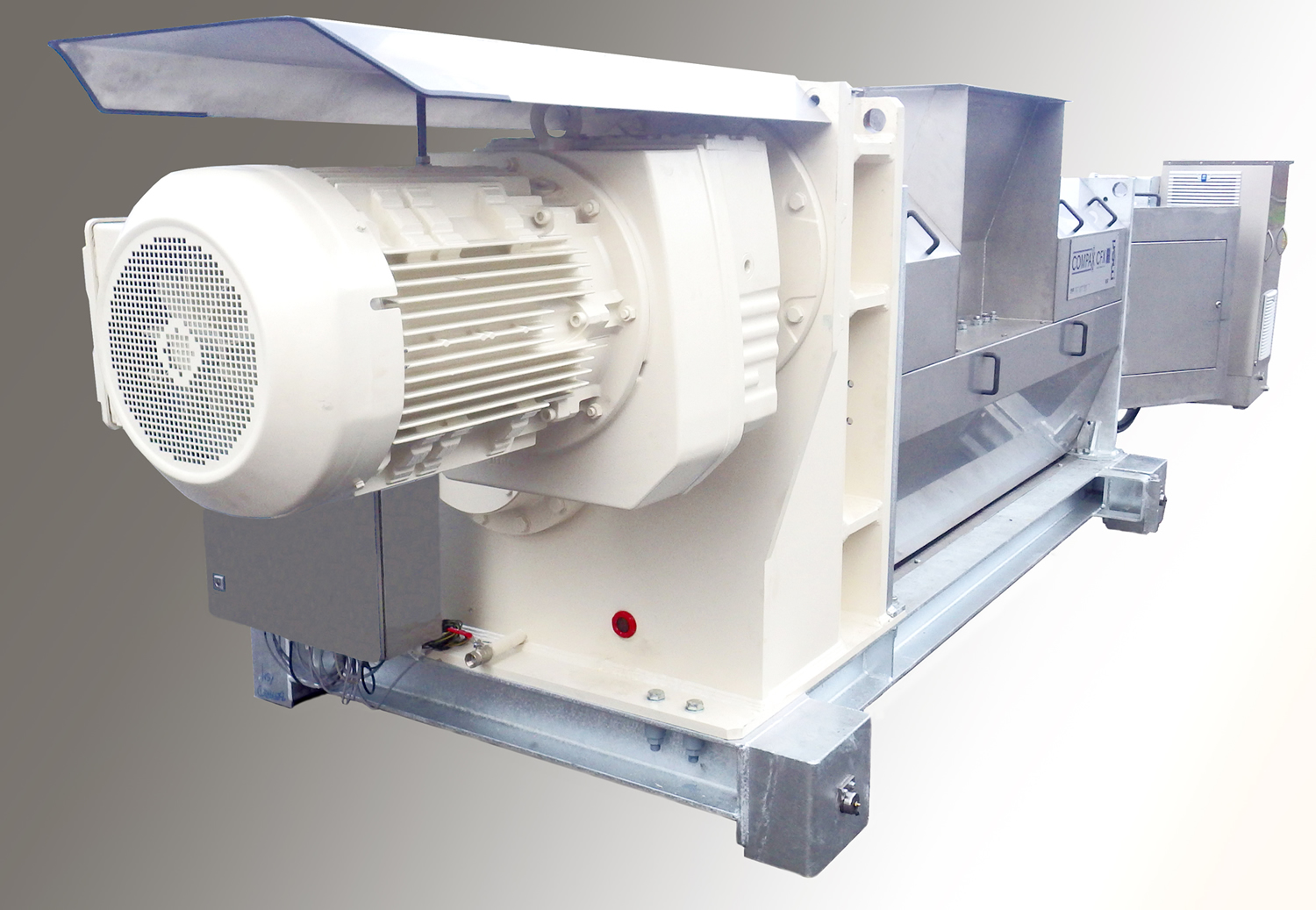

COMPAX CFX-R 80 – Screw Compactor

The Compactor with the HIGHEST CAPACITY & POWER available on the market

[bws_pdfprint_pagebreak]

COMPAX CFX-R 80 – Screw Compactor

The Compactor with the HIGHEST CAPACITY & POWER available on the market

Technology

The COMPAX 80 R – Screw Compactor dewaters Lightweight Coarse Rejects from Pulping, Whole Screening and other De-trashing Systems. The slow speed – high torque- rotating Screw presses the Residuals to be dewatered through a Tube Screen Pipe against a Hydraulic operated Twin Flap which generates extreme high counter pressure. Surface water is pressed through the half screens, and collected in the filtrate plan.

The intelligent control & monitoring system allows the COMPAX 80 R to operate with different and/or oscillating Residual Quantities by variating Screw Speed, Press Flap Angle, Torque, Counter Pressure. Depending on the type of material the COMPAX 80 R achieves the 70% TS dryness.

The COMPAX 80 R operates 24/7, up to 10.000 h in a row depending on the Residual characteristics, designed for lowest possible and fast maintenance to reduce cost & downtime.

Features

- Intelligent Machine and Operation Monitoring Control, operation with changing throughputs achieving constant highest pressing results at lowest Energy Consumption

- High Throughput up to 90 BDMT/d, Highest Dryness up to 70% TS,

- Sturdy Purpose Designed Gearbox with Std. SEW Gearmotor for highest Torques, Hydraulic Twin Press Flaps, hinged Press Head and flanged Screw for easy exchange

- Wear Resistant & Low Maintenace Design, highest 24/7 Reliability up to 10.000 h continuous operation

- Slide In-/Out Installation for easy and fast maintenance access

- Exchange, Refurbishment & Service Programs for Screws, Screens & other

Why to buy

- Market Leading Reject & residual Compactor with more then 500 Installations WW

- Next Gen. Intelligent Control optimizes significantly Performance and reduces Wear

- Highest 24/7 Compacting Performance with Lowest Maintenance & Energy Consumption

- Automatic Operation with different throughput achieving highest dryness up to 70% TS

- Capacity up to 90 BDMT/day equal to aprox. 350 MT/d of Wet Reject at ca.25% TS

- Designed for Easy Maintenance and all Wear Part can be refurbished for Maximum Sustainability

[bws_pdfprint_pagebreak]

Typical & Proven Process Applications

- Dewatering and Pressing Lightweight Reject from Pulping

- Pressing “Pre- Treated” Lightweight Reject from Drum Pulper

- Dewatering and Pressing Lightweight Reject from De-Trashing Sorting Drum

- Dewatering and Pressing Lightweight Reject from Hole Screening

- Dewatering and Pressing Reject form Hole Screening

- Dewatering and Pressing Reject from Combi Sorter, MODU Screens or similar

See as well the following Products

- COMPAX CFX 60R and CFX 50R

- COMPAX CFX- F 50, 60 for Fibrous Residual Material

- ECOMPAX ECX the Simplified Version

- MBX- Belt Conveyors and MCS- Container Stations a.m.mm

- RSP Sludge and Fiber Residual Screw Press RSP 1150,800, and 650

- Reject Pre-Dewatering with ELEPHANT Disk Thickener

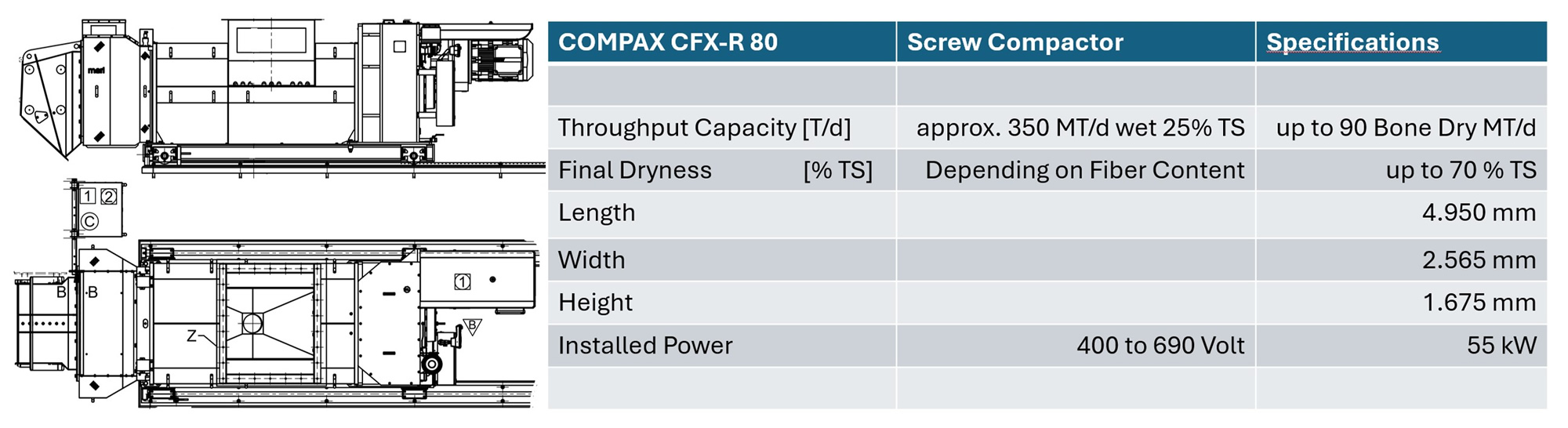

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]