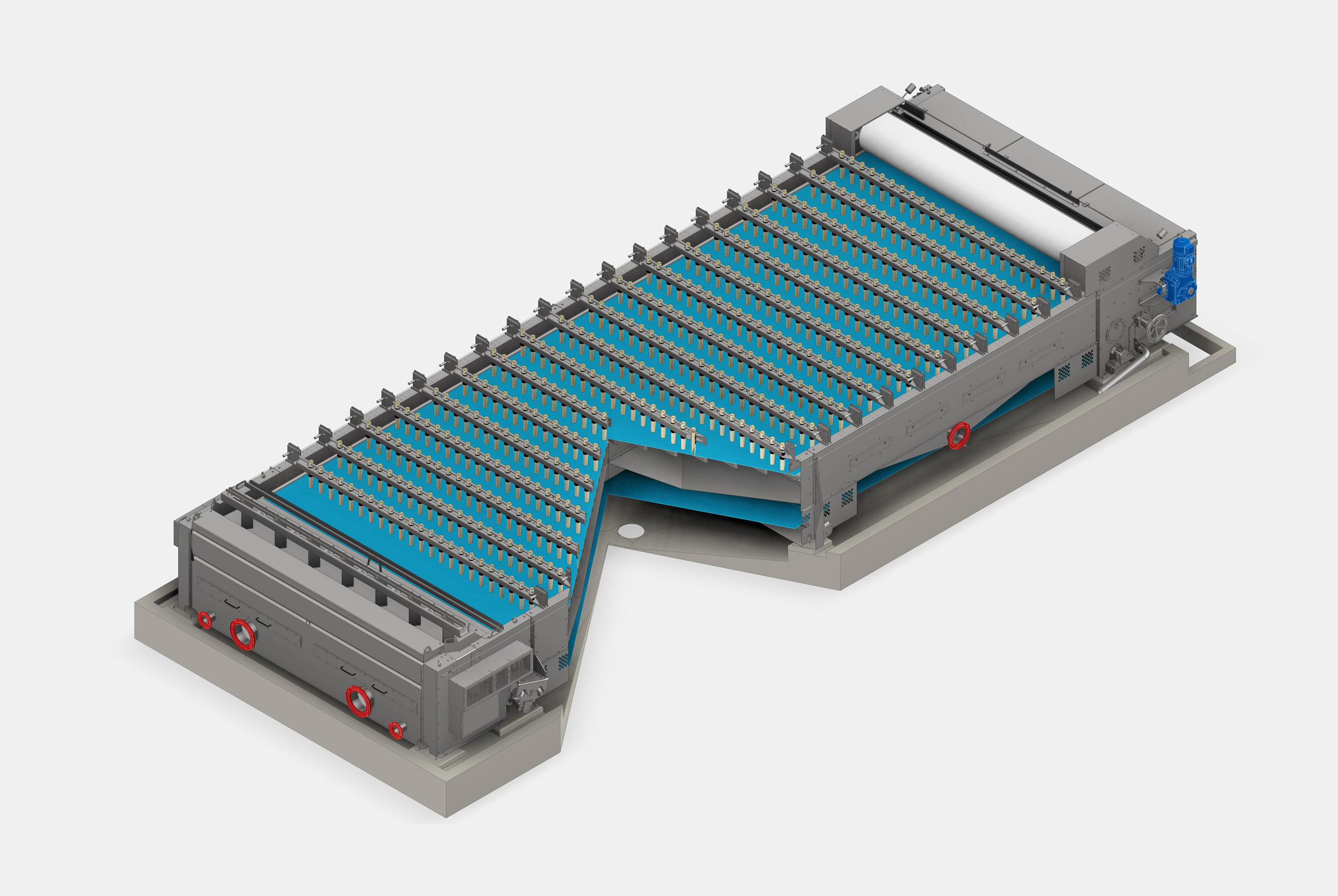

BLUEDRAIN BDL – Belt Thickener

High Performance gravity table

[bws_pdfprint_pagebreak]

BLUEDRAIN BDL – Belt Thickener

High Performance gravity table

Technology

The BlueDrain gravity table is a high-performance continuous belt thickener for the pre-dewatering/ thickening of suspensions e.g. sludge from paper production process & other industries. The flocculated sludge is fed through the head box and distributed over the entire working width of the filter belt. Water flows by gravity through the filter belt while the solids in the water are retained & thickened on its surface. Multiple rows of sludge chicanes and a pressure drum before the discharge end of the table improve the dewatering of the sludge layer. The thickened sludge cake is lifted off by a pressure adjustable take-off doctor blade. A shower with flat jet nozzles is cleaning the filter belt in a washing box.

Features

- Modular Design (width up to 4 m, length up to 12 m) allows adaption to wide range of inlet consistencies and sludge quantities

- Effective belt cleaning with flat jet nozzles (Stamm Shower Pipe)

- Pneumatic belt centering/ tracking system with limit switches

- Pneumatic belt tensioning system to avoid belt slipping

- Multiple chicane rows and floating dewatering roll ensure highest possible thickening efficiency

- Adjustable take-off doctor blade pressure by counterweight system

- Ring Injector – Static mixer & Injection point for efficient polymer mixing achieving lowest possible Chemical Consumption

Why to buy

- Multiple chicane rows and dewatering roll ensure highest possible thickening efficiency &discharge dryness up to 20% at lowest Chemical consumption

- Low OPEX by long life filtering belt & reliable mechanical components

- 24/7 trouble free operation supported by highly reliable belt tracking and belt tension adjustment system

- Highest Throughput up to 180 bdt/d

- Easy installation due to pre-assembled machine elements and modular design

- Safe and clean operation due to closed frame design & optional covering hood

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Thickening/ Pre-Dewatering of thin sludge & reject suspension

- from Cleaning & Fine Screening

- with or w/o defined content of excess bio sludge from Effluent Water Treatment

- from Water Clarification (DAF units, Primary Clarifiers, …)

- from De-Inking Plants

- Filtration/ Fibre Recovery Unit for Process Waters

- White Water from Decor Paper Manufacturing

See the following Products as well

- Sludge/Reject Pre-Dewatering by ELEPHANT

- COMPAX CFX-F 50,60 & 80

- MINIPRESS MPX 30, 40 & 50

- RSP- Sludge and Fiber Residual Screw Press RSP 1150, 800 & 650

- MSC- Spiral conveyors and related bunker- & container filling- & distribution systems

- POLYMERI Polymer Preparation Unit

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]