BELT CONVEYOR MBX

World leading Reject Conveyor

[bws_pdfprint_pagebreak]

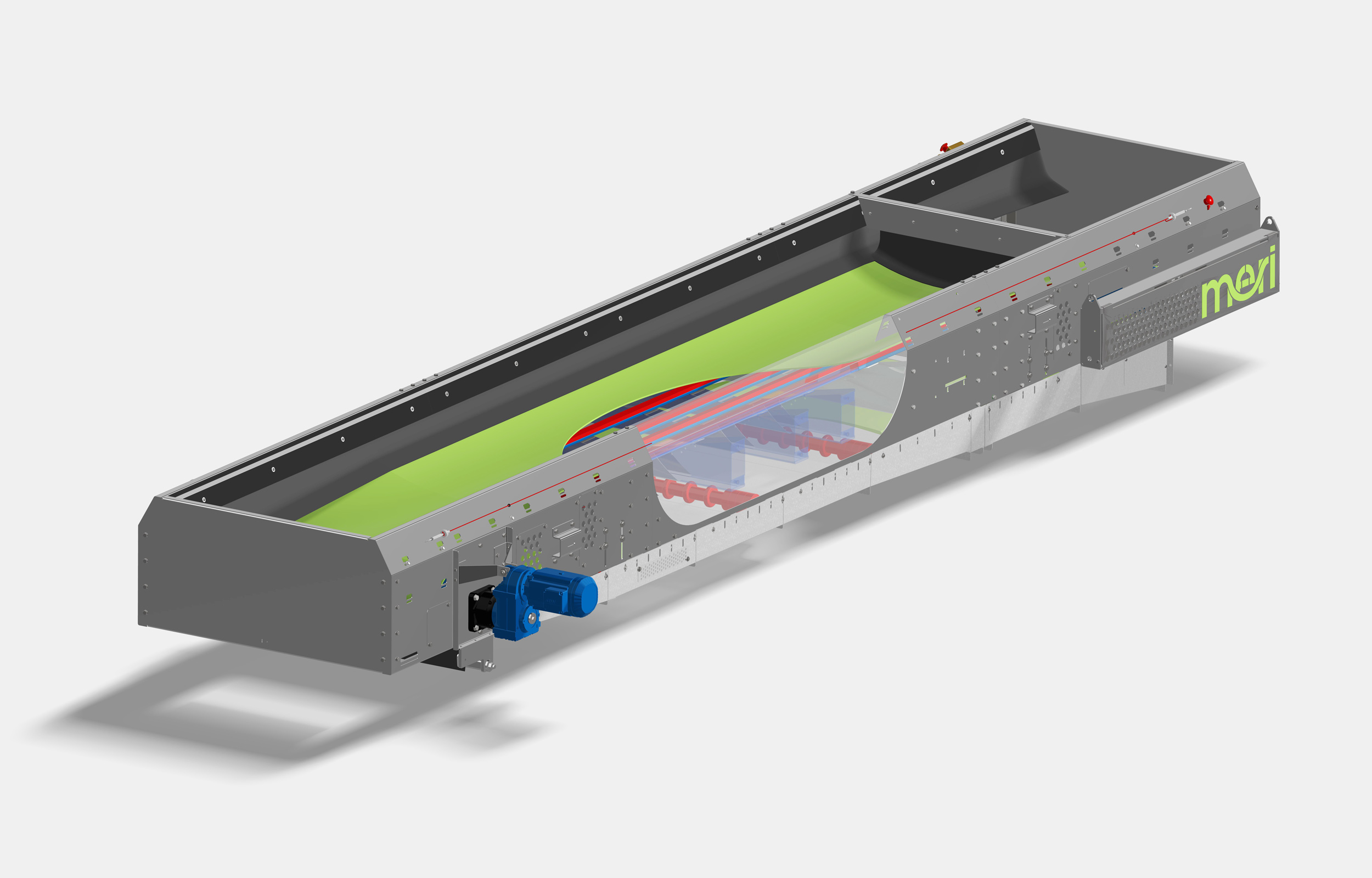

BELT CONVEYOR MBX

Technology

The Conveying of Rejects and Residuals is challenging, in most cases standard belt conveyors are inappropriate as to many moving parts spin and rollup contaminants and function is not reliable.

The MERI MBX Belt Conveyor Series is fully modular (width, length, section elements) and was specially designed for operation in the paper industry. Applications are transport of pre-dewatered rejects and other challenging residuals, as wet & dry light weight rejects & mixed heavy and light weight rejects occurring from pulpers- and washing drums.

The moulded belt runs on longitudinal sliding bars, with high side guidance which secure clean conveying without spillages. The number of turning parts is reduced to a minimum which prevents longer particles to spin around rollers and movable parts and reduces wear and maintenance effort to a minimum.

Segmented water pans ensure clean environment and easy access. Installation in- and out- door; without and with cover segments is possible. Due to modular design several frame material combinations such as galvanized mild steel or AISI304 are available.

Generous free conveyor width and variable speed drive ensures large throughput without blockage and spillages also over long distances.

Features

- Conveying on sliding bars with lowest amount of turning parts for reduced wear and prevention of spin ups by tapes and long particles as well as low power consumption

- Clean conveyor belt due to special advanced cleaning blade- technology

- Variable speed with std. SEW gearmotors for optimum velocity and low power consumption for reliable 24/7 continuous operation

- Simple tension concept with backside bearing blocks for easy adjustment

- combined perforated side covers for highest operational safety and quick cleaning access and “stable straight on”- running- behaviour”

- Segmented filtrate pans in Stainless Steel

- Multiple belts surface characteristic available to support self- clean effect

Why to buy

- Long time experienced conveying technology with over 1150 of belt conveyors in Paper Industry worldwide

- Reliable transportation of large discontinuous quantities by wide free belt width

- Moulded belt section- provides clean transport without spilling compared to flat belts

- Low belt friction on sliding bars secures lowest energy consumption and maintenance free operation

- Modular frame design and simple support feed connection for quick initial erection.

- Easy maintenance and erection due to quick exchangeable doctor blades, sliding bars, lower return idlers, clamped side rubbers, perforated side covers and modular design

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Conveying of Light weight Reject from Pulping wet or dry.

- Fibrous rejects/sludges wet or dry.

- Transportation of bulk reject, pulper rope in certain length or pre- shredded.

See the following Products as well

- Container- Stations MCS – lateral & rotating

- MSC – Spiral conveyors

- Pre- Dewatered trash/reject from TSX-SCREENEX

- LION shredders

- COMPAX CFX- R & F

- MINIPRESS MPX

- Pre- thickened residuals from Elephant- Filter, Sediphant & Screenex

- RSP- screw press sludge

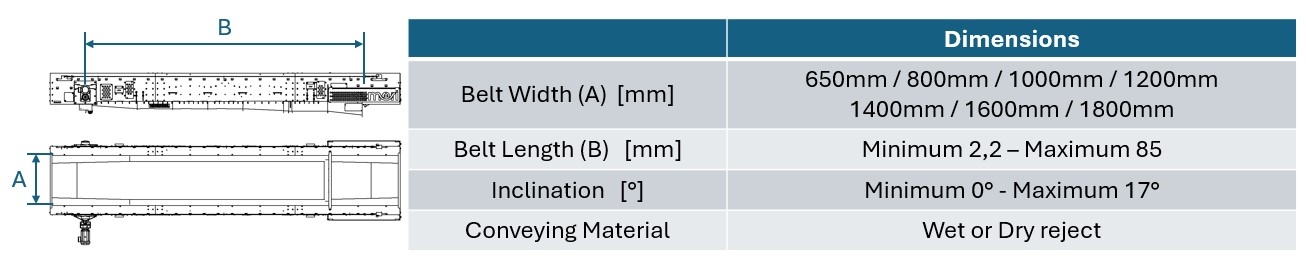

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]