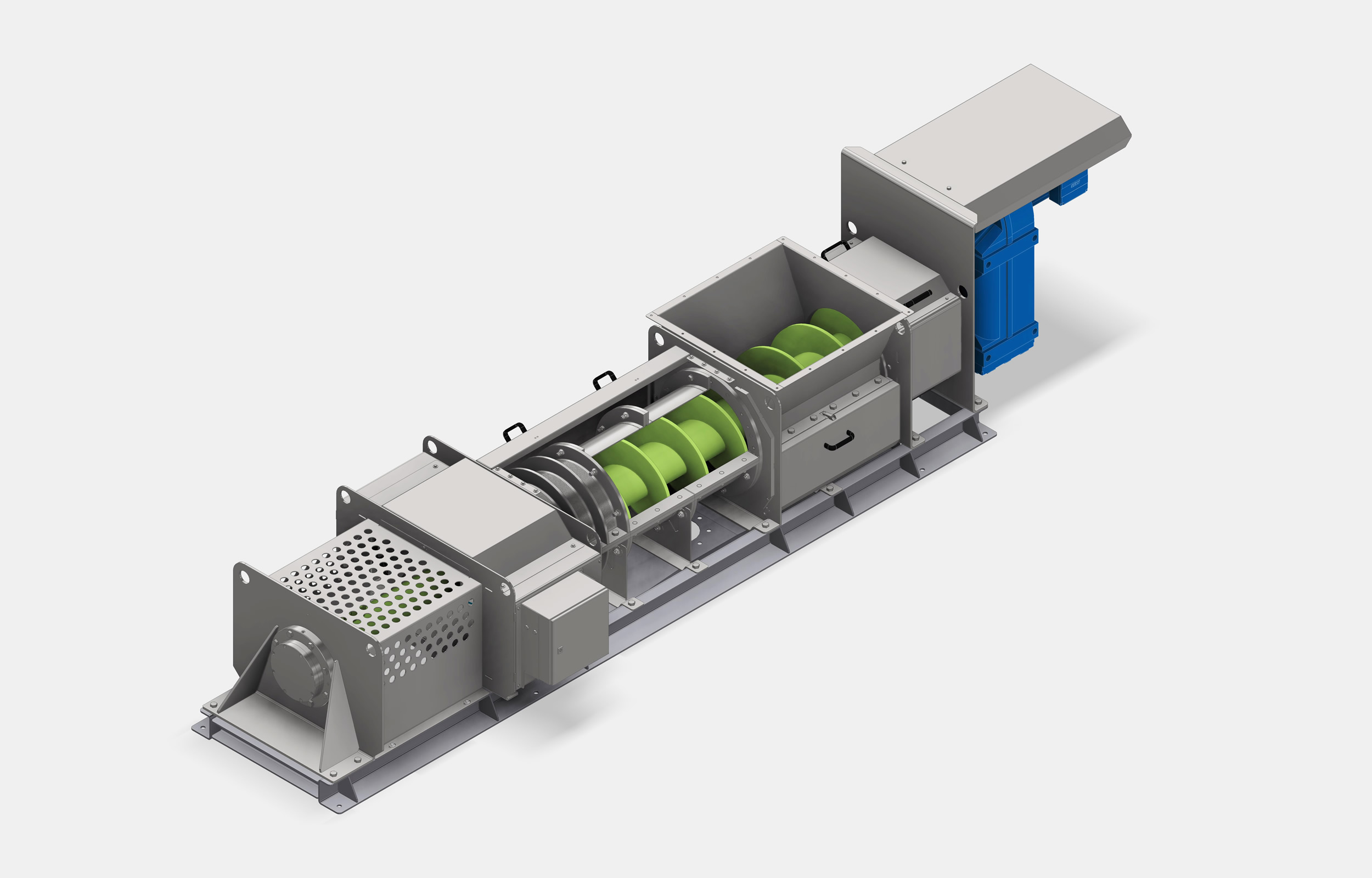

MINIPRESS MPX Screw Press

Cost Effective Screw Press for Fibrous Rejects and Sludges

[bws_pdfprint_pagebreak]

MINIPRESS MPX Screw Press

Technology

The Minipress is a compact screw press designed to dewater fibrous sludges, reducing handling, transport and disposal costs for paper and plastic recycling industries. It operates by feeding the fine rejects/sludges onto a press screw with cylindrical shaft and constant pitch. The material is initially dewatered by means of gravity and agitation of the screw, and then pressed against the plug formed by the preceding material at the press nozzle, achieving the final dryness. A twin-flap pneumatic system regulates the counter-pressure, maintaining even dewatering and high dryness at the discharge end. Its modular design allows customization based on material characteristics, like fiber content, consistency, and dewatering properties, enhancing operational efficiency and adaptability for varied industrial needs.

Features

- Single flight screw with bearings on both ends and cylindrical shaft.

- Press nozzle with twin flaps for uniform counter pressure operated by air bellows.

- Torque control (by proportional valve) for constantly high discharge dryness.

- Modular exchangeable half screens with different hole patterns allow adaptation to various sludge types.

- Compact, low-maintenance design with accessible screens for easy servicing.

- Machine body and base frame in HDG or stainless steel. Half screens and screw in wear-resistant or stainless steel depending on the application.

Why to buy

- Low capital and installation costs allow multiple de-central installations.

- Low OPEX and minimal maintenance due to screen design with halve screens and minimized amount of wear parts.

- Constantly high discharge dryness up to 55 % due to torque control.

- Low energy consumption.

- Various available press screw diameters and length allow machine adaption to wide range of feed loads and consistencies (1 – 25 bdt/day; 2 – 15 %).

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Dewatering of thickened Sludge & Reject mixtures

- from Cleaning & Fine Screening

- from Coarse Screening

- from Water Clarification

- from Effluent Water Pre-Treatment (DAF units, Primary Clarifiers, …)

- Dewatering of Residuals

- from Process Water Treatment of Plastic Recycling Plants, of Air Washers in MDF Production,

See the following Products as well

- Sludge/Reject Pre-Dewatering by ELEPHANT, BlueDrain Belt Thickener.

- Sludge Press RSP 65, 80 & 115

- COMPAX CFX-F 50, 60 & 80

- MSC- Spiral conveyors and related bunker- & container filling- & distribution systems

- POLYMERI Polymer Preparation Unit

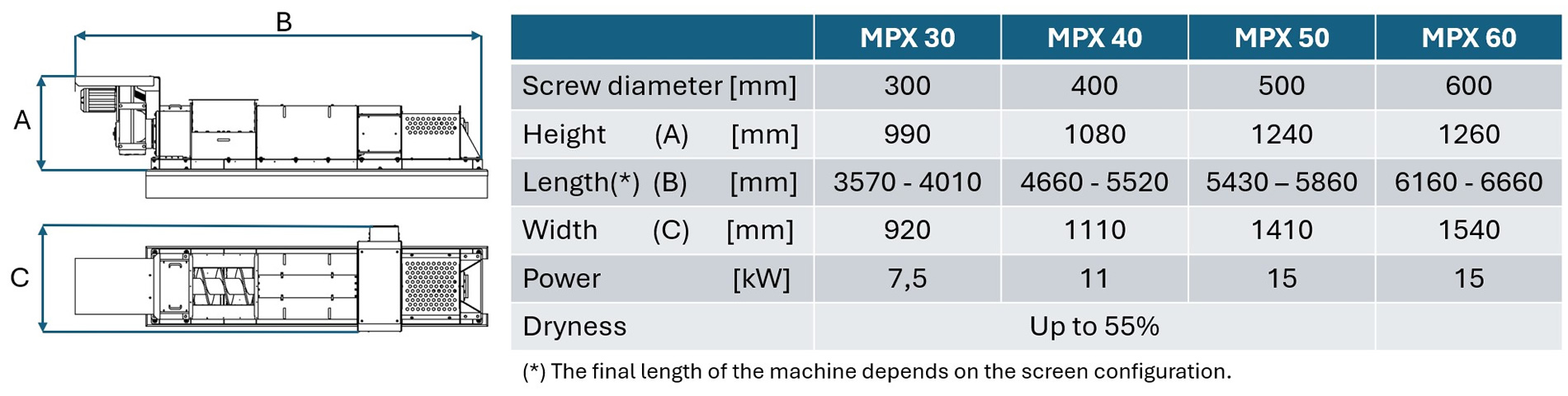

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]