SEDIMATOR SMF

[bws_pdfprint_pagebreak]

SEDIMATOR

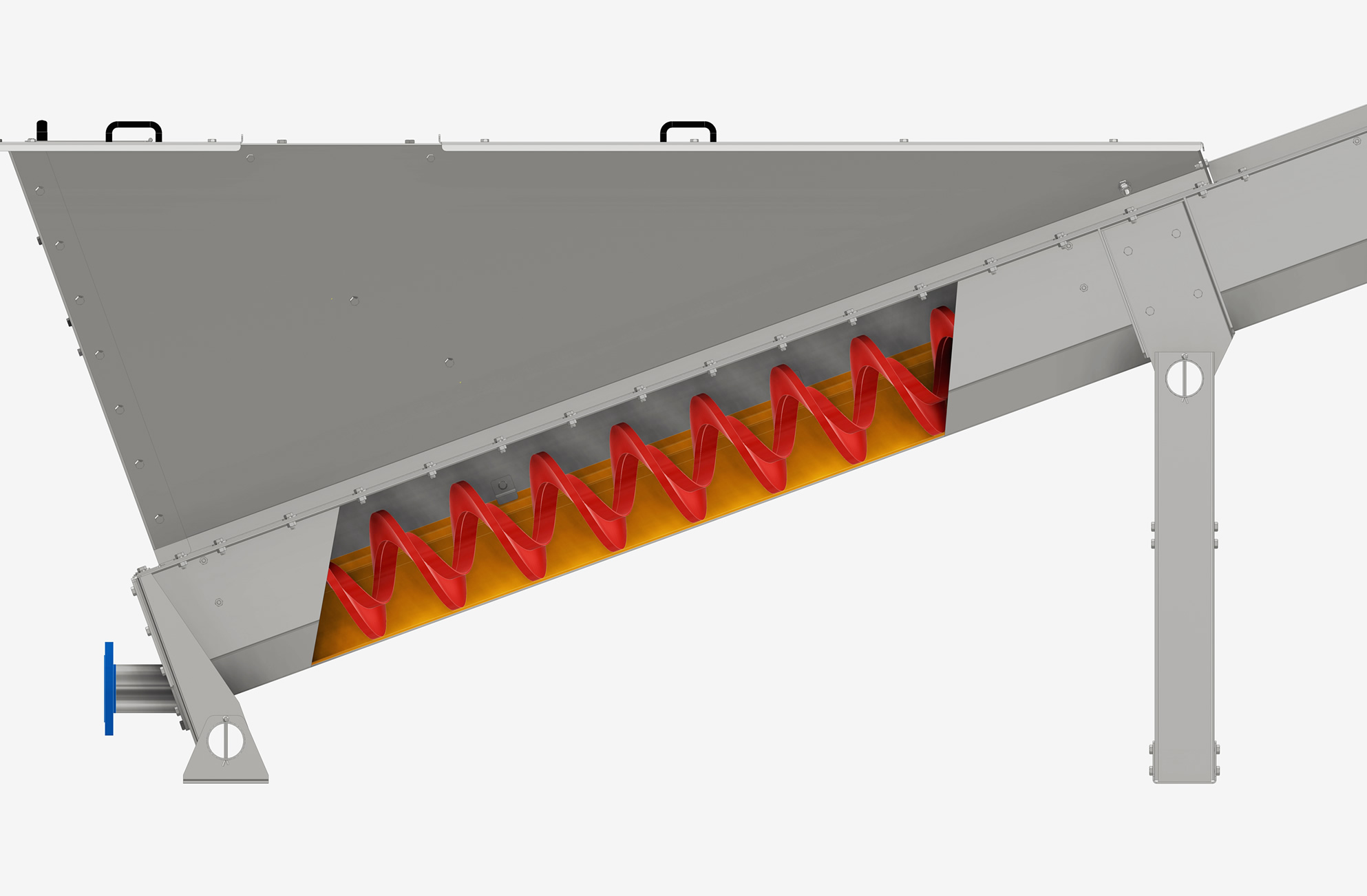

Technology

The SEDIMATOR SMF separates small sediments and small heavy weight reject (coarse sand, small stones, glasses & staples) from High- Consistency Cleaners

The entering reject flow is discharged onto a deflector plate which separates the suspension into heavy particles, which are settling to the bottom of the sedimentation tank and into water which overflows the large barrier at the backside before being discharged. The settled heavy weight particles are conveyed and discharged at the upper spiral frontside.

The large sedimentation area combined with the continuous slow speed turning conveying spiral secures an equal sedimentation process without disturbing the flow pattern of the sedimentation process providing nearly fibre free reject discharge.

Features

- Large sedimentation- tank and generous overflow barrier secures save operation without spillages also at variating inlet folws

- Slow turning spiral and special resistant wear lining for longest life- time and low maintenance efforts of active and static parts

- Special flow pattern with guide plates to reduce turbulence and improve the settling process

- Hing able support joint for simple and quick installation

- Large inspection openings for easy access and monitoring

- Sturdy SEW gear motor with flanged shaft and slow speed ensures low energy consumption and high reliability in 24/7 continuous operation

- Refurbishment service available for spiral

Why to buy

- SEDIMATOR technology with 300 installations WW.

- Reliable handling of large throughputs by big tank and large overflow barrier

- Slow spiral- speed for smooth sedimentation process ensures nearly fibre free discharge and lowest maintenance at lowest Energy consumption

- High 24/7- hour continuous performance and clean environment also with varying inlet flow

- Applications in “up to 1400 BDTPD stock preparation lines” with only one unit are possible

- Easy maintenance design with possibility to refurbish spiral combined with quick access and fast exchangeability of spiral, wear lining and std. gear motor

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Sedimentation and discharge dripping wet of “Small Heavy weight” rejects in stock- prep.- lines

- from HD/HW- Cleaners directly after pulping

- from HD/HW- Cleaners inside hole screening process, Combisorter- Cleaners or from junk traps of Moduscreens or similar

- Sedimentation of “Small Sand” from HD/HW Cleaners in filtrate cleaning applications

- HD/HW- Cleaners in filtrate of disk- thickeners

- HD/HW- Cleaners in filtrate of gravity- tables

See as well the following Products

- Sedimentation and pre- thickening by SEDIPHANT

- MSC- Spiral conveyors and related bunker- & container filling- & distribution systems

- Reject Pre- Dewatering with ELEPHANT Disk thickener

- Reject Pre- Dewatering with BLUE DRAIN Gravity table

- COMPAX CFX-F 50,60 & 80

- MINIPRESS MPX40, 50

- RSP- Sludge and Fiber Residual Screw Press RSP1150,800 & 650

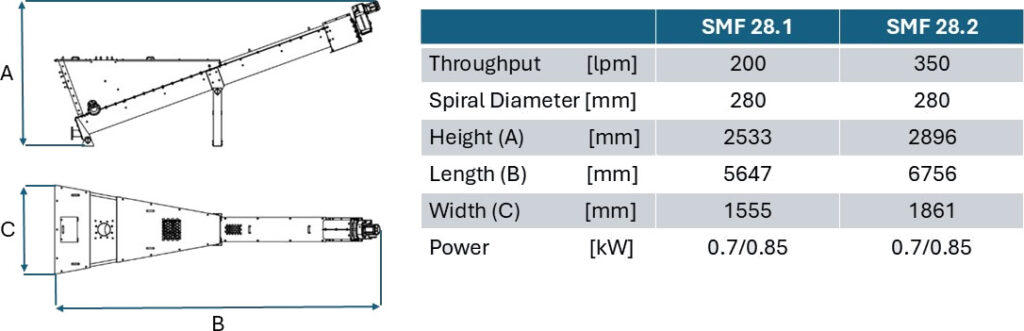

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]