DELTAPURGE NG

[bws_pdfprint_pagebreak]

DELTAPURGE NG

Technology

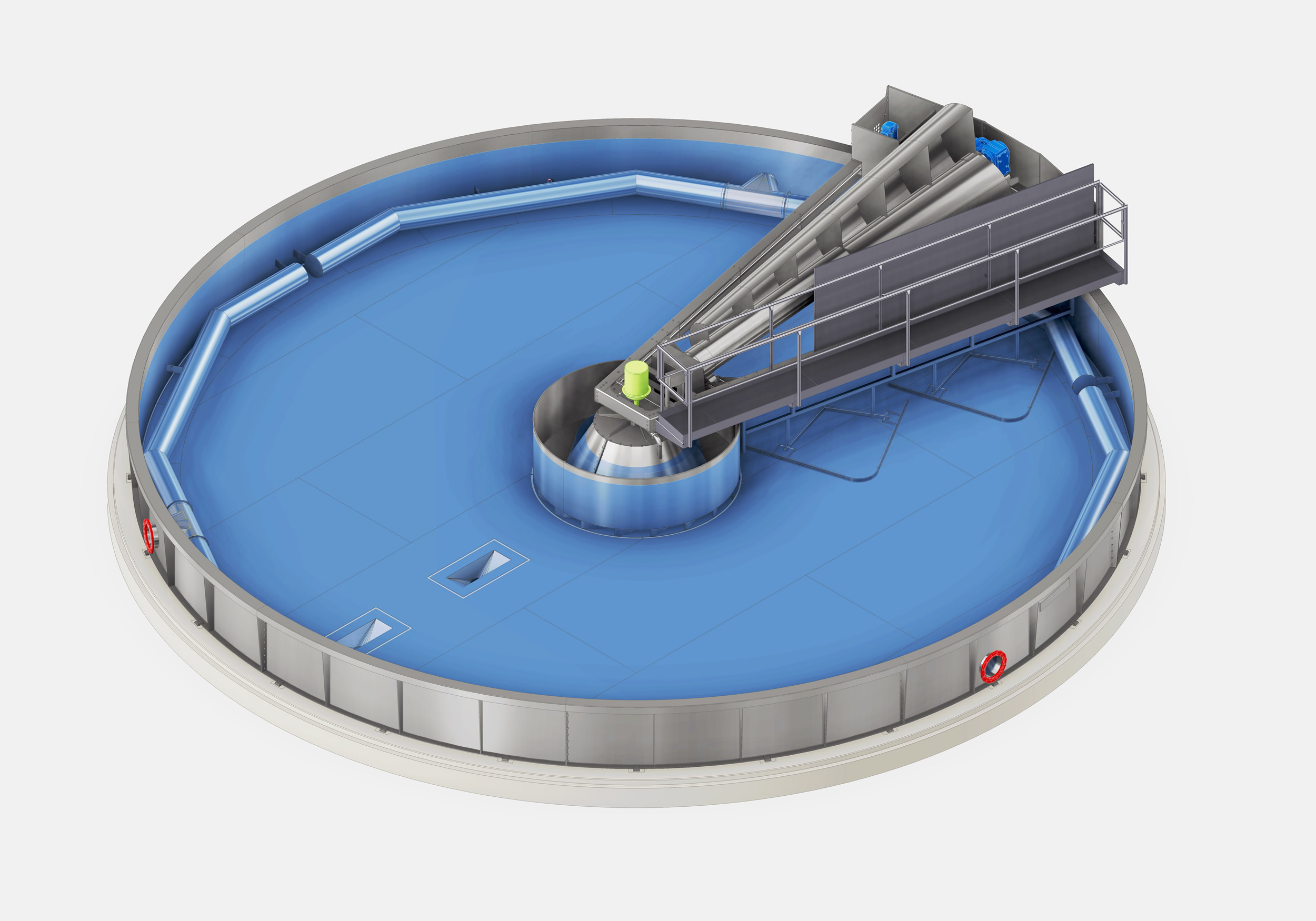

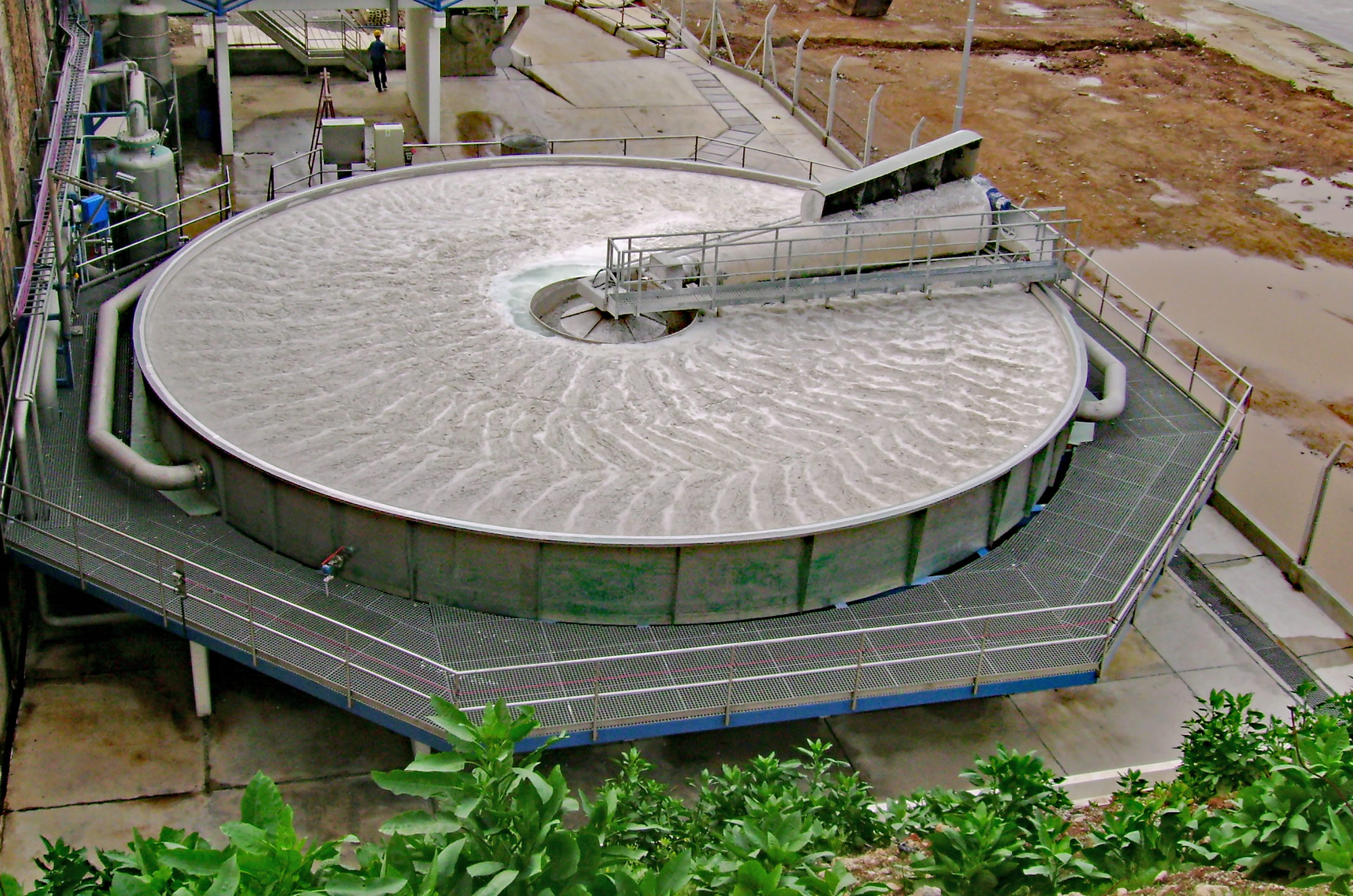

The Deltapurge is a highly efficient circular dissolved air flotation system designed for the water clarification and the removal of solids in paper industry water circuits. The circular design provides clean open flotation area and improves the removal of suspended solids, equipped with a circulating bridge, spiral scoop and a reinforced bottom scraper. The Universal Dissolving System (UDS) generates small air bubbles that are added to the feed stream before it enters the Deltapurge to enable solids separation in the flotation process. Solid removal can be enhanced by multiple combined process steps as coagulation, flocculation or adsorbtion for binding (dissolved) solids to floating micro bubbles. The self-cleaning tank ensures high reliability, low maintenance and continuous operation.

Features

- Circular flotation setup with round tank design ensures optimized hydraulic flow for solid separation and avoids buildup in dead corners.

- Equipped with a spiral scoop bridge for effective flotation sludge skimming at highest consistency and sturdy bottom scrapers for heavy sludge removal.

- Clear Water Wall allows good access and easy cleaning

- Low turbulence flow concept avoids shareforces to flocs and provides lowest chemical consumption for sustainable operation

- Suitable for various flow rates without requiring constant flow

- Central bearing with only six moving parts for high reliability and minimal wear

Why to buy

- Consistently removing solids from process water leads to improved operation and extended equipment life in more than 500 DAF installations worldwide

- The Deltapurge allows wastewater reuse and helps to decrease freshwater consumption

- Durable components and efficient design minimize maintenance and OPEX

- Effectively reduces odorous emissions, creating a cleaner, more compliant work environment

- Self-cleaning feature and sludge flotation by micro-bubbles prevent downtime and ensure continuous operation

- inside or outside installation allows flexibility and scaling for different mill sizes

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Clarification of filtrate and process loops

- Removal of colloidal contaminants, dissolved particles, ash and micro stickies

- PM White Water treatment and washer filtrate clarification

- Closed-loop water recycling to reduce freshwater demand

- Clarification of primary and secondary mill effluents

See the following Products as well

- Universal Dissolving System

- POLYMERI & DOSING STATION

- TAL & TAM TAURO

- ELEPHANT

- RSP Sludge Press

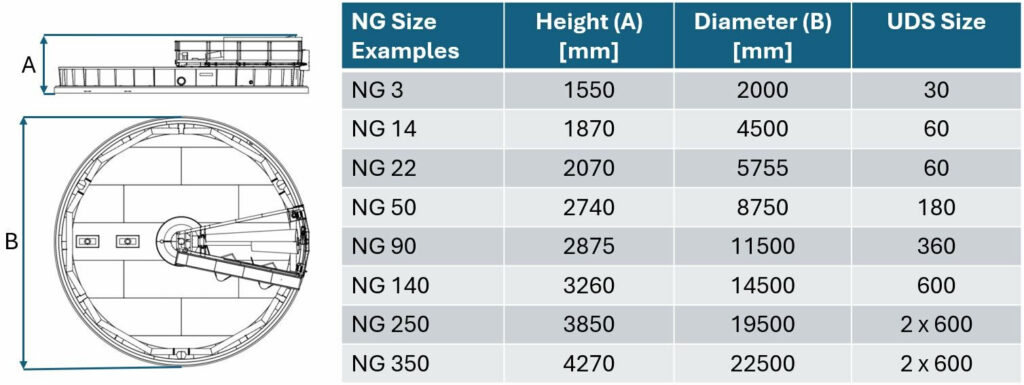

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]