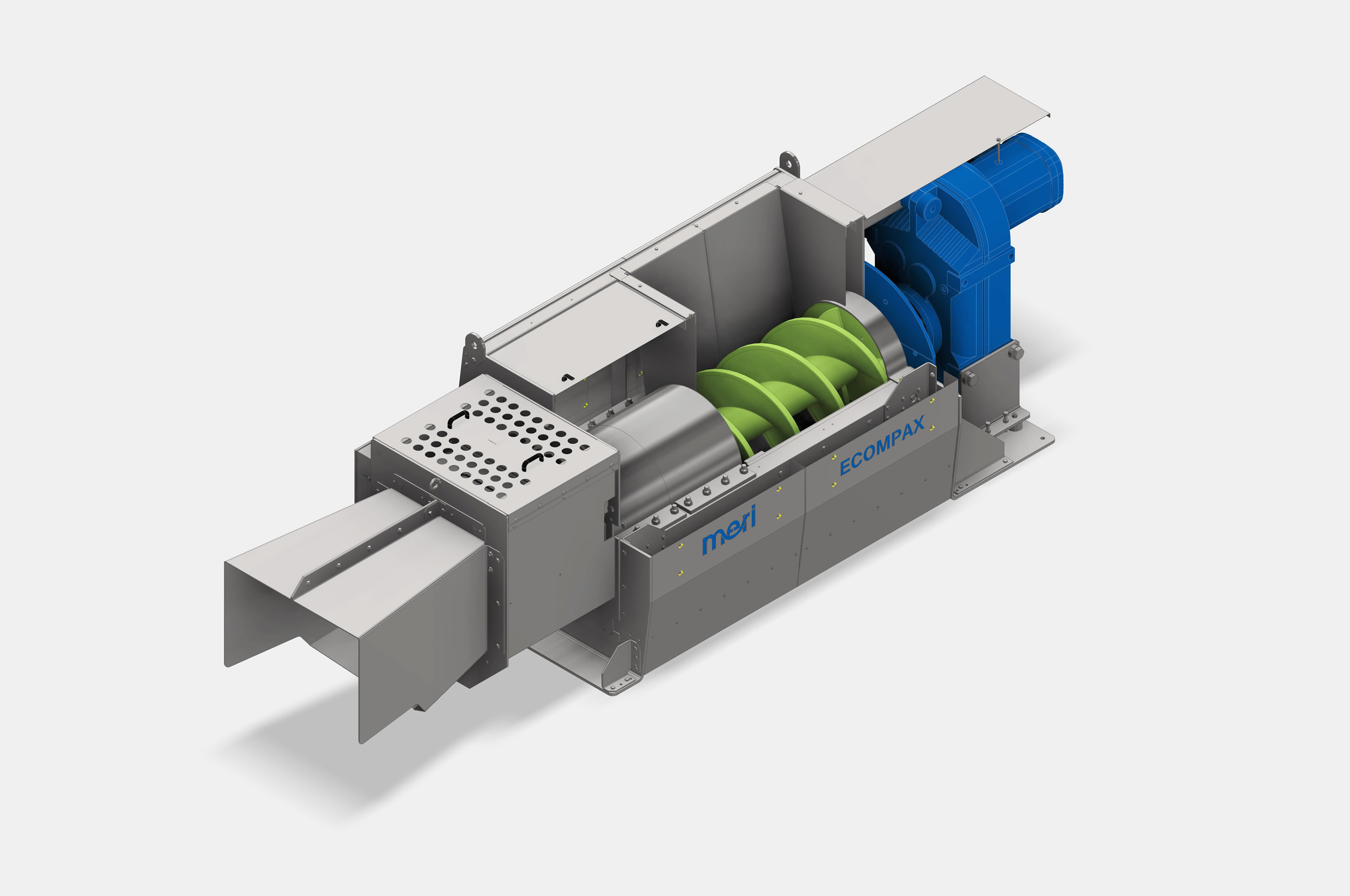

E-COMPAX

Cost Effective Lightweight Reject Dewatering Solution

[bws_pdfprint_pagebreak]

E-COMPAX

Cost Effective Lightweight Reject Dewatering Solution

Technology

The Ecompax is a compact screw press designed to dewater lightweight coarse rejects, reducing handling, transport and disposal costs for paper recycling industries. The material is initially dewatered by means of gravity and then pressed against a press nozzle actuated by a pneumatic cylinder.

The SEW standard gear drive is operated with a Frequency Converter (MCC) simple speed adjustment depending on volume in inlet hopper. The Pneumatic Counter Pressure is adjusted manually. The ECOMPAX provides Simple and Basic dewatering / Pressing Operation achieving dryness levels between 45 to 55% of dryness.

Its open discharge design prevents plugging, ensuring smooth and cost-effective operations.

Features

- Simple Operation, and reliable functionality for basic dewatering and pressing operation

- Throughput capacity between 25 and 40 t/d

- Compact design lowers investment costs, ideal for small and mid-sized plants.

- Easy refurbishment programs for screws, screens, and other wear parts, ensuring long-term sustainability.

Why to buy

- Cost-effective design reduces initial CAPEX.

- High availability and easy maintenance with flanged screw minimize downtime.

- Sustainable operation with optimized Reject-Handling and reduced landfill costs.

- Low OPEX due to efficient and reliable performance.

- Reduction in disposal and transport costs with high dryness levels.

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Dewatering and Pressing Lightweight Reject from Pulping.

- Dewatering and Pressing Lightweight Reject from Hole Screening.

See as well the following Products

- COMPAX CFX 60R and CFX 50R.

- COMPAX CFX- F 50, 60 for Fibrous Residual Material

- COMPAX CFX 80R

- MBX- Belt Conveyors and MCS- Container Stations a.m.mm

- RSP Sludge and Fiber Residual Screw Press RSP 1150,800, and 650

- Reject Pre-Dewatering with ELEPHANT Disk Thickener

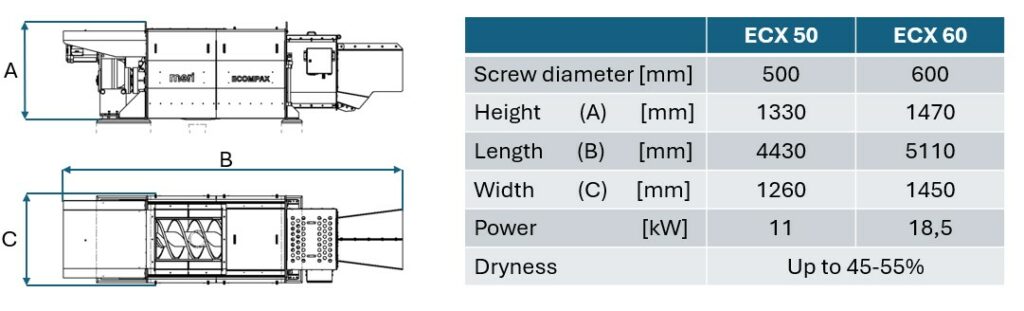

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]