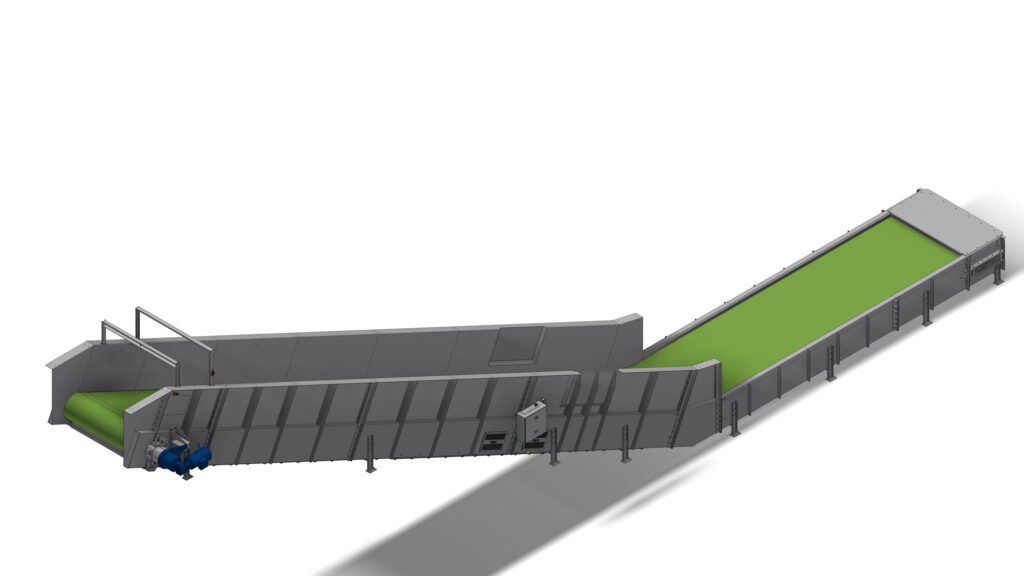

MMH-FC – Meri Material Handling Feed Conveyor

The Feed Conveyor is designed for ease of maintenance, efficient erection, low installation costs, and superior durability

[bws_pdfprint_pagebreak]

MMH-FC – Meri Material Handling Feed Conveyor

Technology

The Feed Conveyor transports loose or baled material to pulper.

The machine build is robust formed, welded and bolted frame promotes long machine life and maximum uptime.

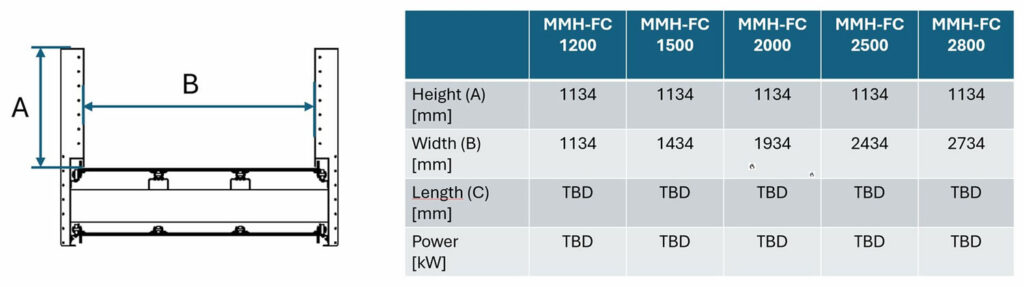

These conveyors are built for harsh applications: millsites, indoor or outdoor installations, Five standard widths are available (1200mm,1500mm, 2000mm, 2500mm, 2800mm), with special widths available upon request.

The Feed Conveyor includes a high torque, low rpm planetary gear drive enabling accurate material flow.

Features

- Available auto lubrication system prevents need for manual lubrication

- Integrated rope e-stop for personal safety

- Scraper station prevents material wrap-around

- 4,5-6m sections for fast erection

- Underbelly pans to keep area clean and safe

- Split sprockets on Drive so shafts don’t need to be removed

- SKF bearings for durability

- High strength roller chain

- Slat accessories available, including pins for dewiring & cleats for loose material transfer

Why to buy

- Many installations in field (300+)

- Our slat conveyors are custom designed to meet the exact requirements of your application but are still built from standard sections to save cost and time.

- Minimum maintenance required

- Lubrication points are accessible without machine disassembly

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Pulper Feed System

- Slat conveyors have applications for all material transporting, from recycling plants to the paper industry, for carrying loose and baled raw material

- Flexibility of design makes our slat conveyors suitable for outside and inside installation, continuous or batch operation, and in various arrangements

- Slats and side walls work together to form a labyrinth seal, preventing material from escaping the conveyor bed and keeping your millsite clean from loose material.

See the following Products as well

- MMH-WCMA – Meri Material Handling Wire Cutter

- MMH-DLAT

- MMH-DMOB – Meri Material Handling Mobile De-wiring

- MMH-DTOP – Meri Material Handling Automatic De-wiring Machine

- MMH-WCOI

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]