CSED – Next generation of Circular Sedimentation Clarifier

[bws_pdfprint_pagebreak]

Technology

Sedimentation is used in Industrial Effluent Treatment for Pre- Clarification (chemical-physical solids removal) before Biological Treatment or as Secondary Clarification after Biological Treatment to remove Excess Bio Sludge and other Residuals.

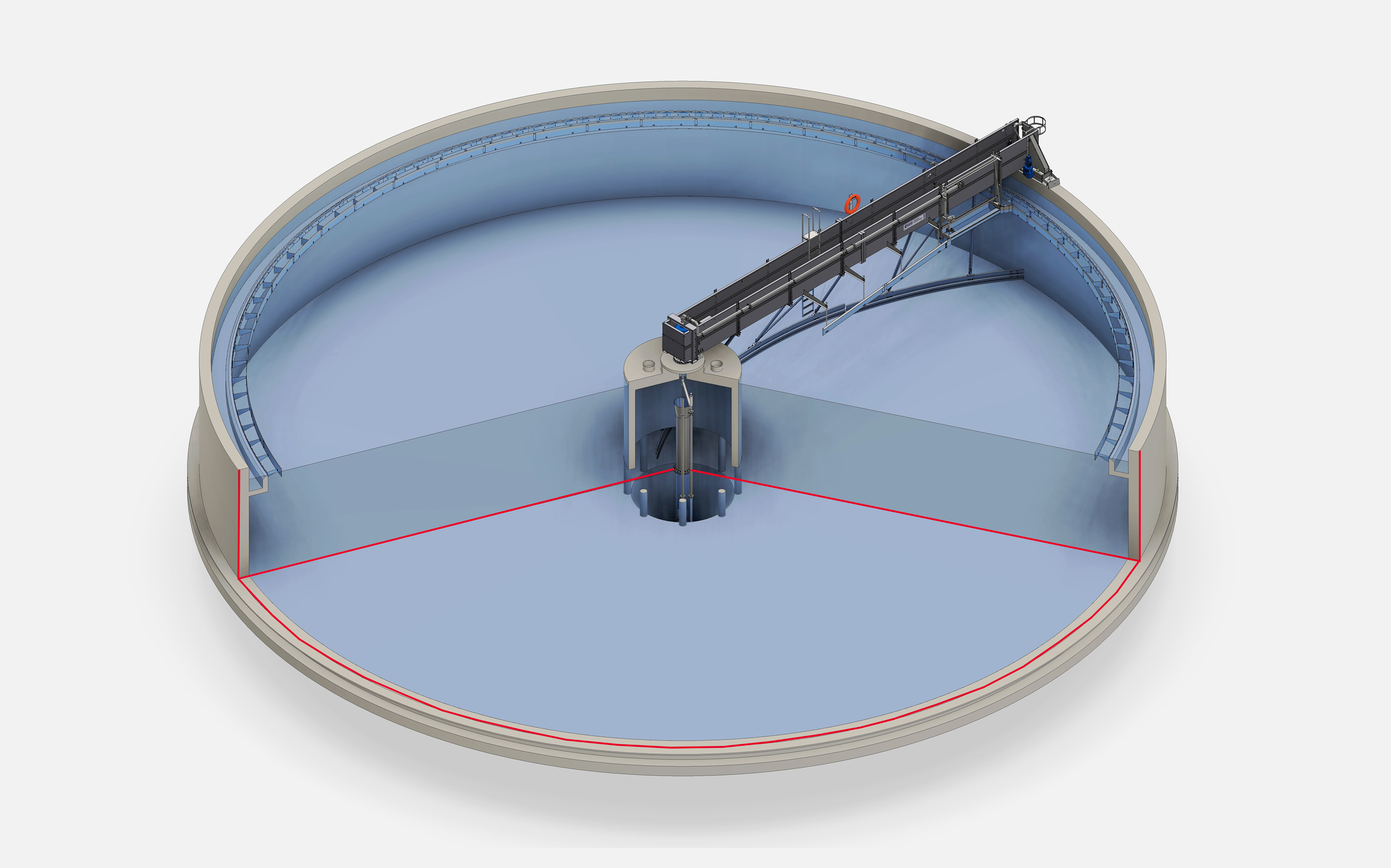

The circular Clarifier Tank is used to separate solids (sludge) from liquids through the process of gravity settling. The Inlet flows from a central feed well towards the outside wall reducing flow velocity and allowing particles / contaminants to sink and settle.

The CSED Shield Version comprises a very slow rotating bridge, which holds and pulls a helix shaped bottom scraper transporting Sediment Solids over the sloped bottom towards the discharge point located in the lowest center point. (typical application- Primary Clarifier)

The CSED Suction Version has slow rotating bridge, which has radially oriented, submerged mounted suction hoods, which tightly overrun the flat tank floor and aspirate Sediment Solids / Flocks. Aspiration can be provided by submerged pumps with speed control or gravity siphon pipe vacuum.

The clarified water overflows a weir on the outer tank rim.

Appearing floating scattered matter is collected by bridge mounted deflection skim plates and forwarded to a “Floating Skimmer Trough” which scoops a thin fluid film with the floated residuals, which is typically pumped to sludge treatment.

Features

- CSED – SHIELD Clarifier with bottom scraper and sloped tank bottom (Primary Clarification) or alternatively CSED – SUCTION Clarifier with submerged mounted radial suction hoods, which tightly overrun and flat tank floor and aspirate sediments (Secondary Clarification).

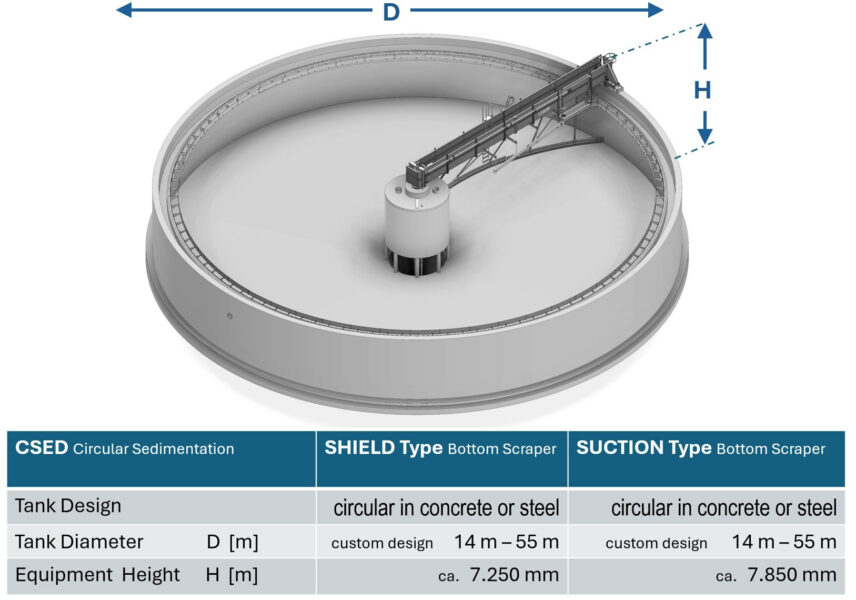

- Circular Tank Design in steel or concrete with diameters between 14 – 55 m

- “Floating Skimmer Trough” which scoops a thin fluid film with the floated residuals

- Modular design allows easy dimension customizing, and reliable functionality with minimum maintenance for best OPEX.

- CSED is available in different Material Configurations as HDG or Stainless Steel

- Extreme sturdy and reliable Design for trouble free performance

Why to buy

- Most advanced Sedimentation Technology for industrial Wastewater Treatment

- Modular 3D design allows easy customizing and cost-effective realization

- CSED design allows SHIELD or SUCTION Technology depending on application

- Modular design with pre-assembled Machine Groups secures fast and costeffective installation

- Multiple Material configurations for machine and tank components available HDG, Stainless, etc.

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Primary Clarification (chemical-physical solids removal) before Biological Treatment

- Secondary Clarification after Biological Treatment to remove Excess Bio Sludge and other Residuals.

- Special Process Applications for solids removal and thickening of FW, WW and other process streams.

See the following Products as well

- RSED Retangular Sedimentation Clarifier

- DINOSCREEN solid removal from U-drains

- Dissolved Air Flotation Clarifiers – DELTAPURGE , TAURO- Series, Basic – and Quadra- Float

- ELEPHANT Disc Thickener

- BLUEDRAIN and RSP Press for Sludge dewatering

- GYROSAND Filtration

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]