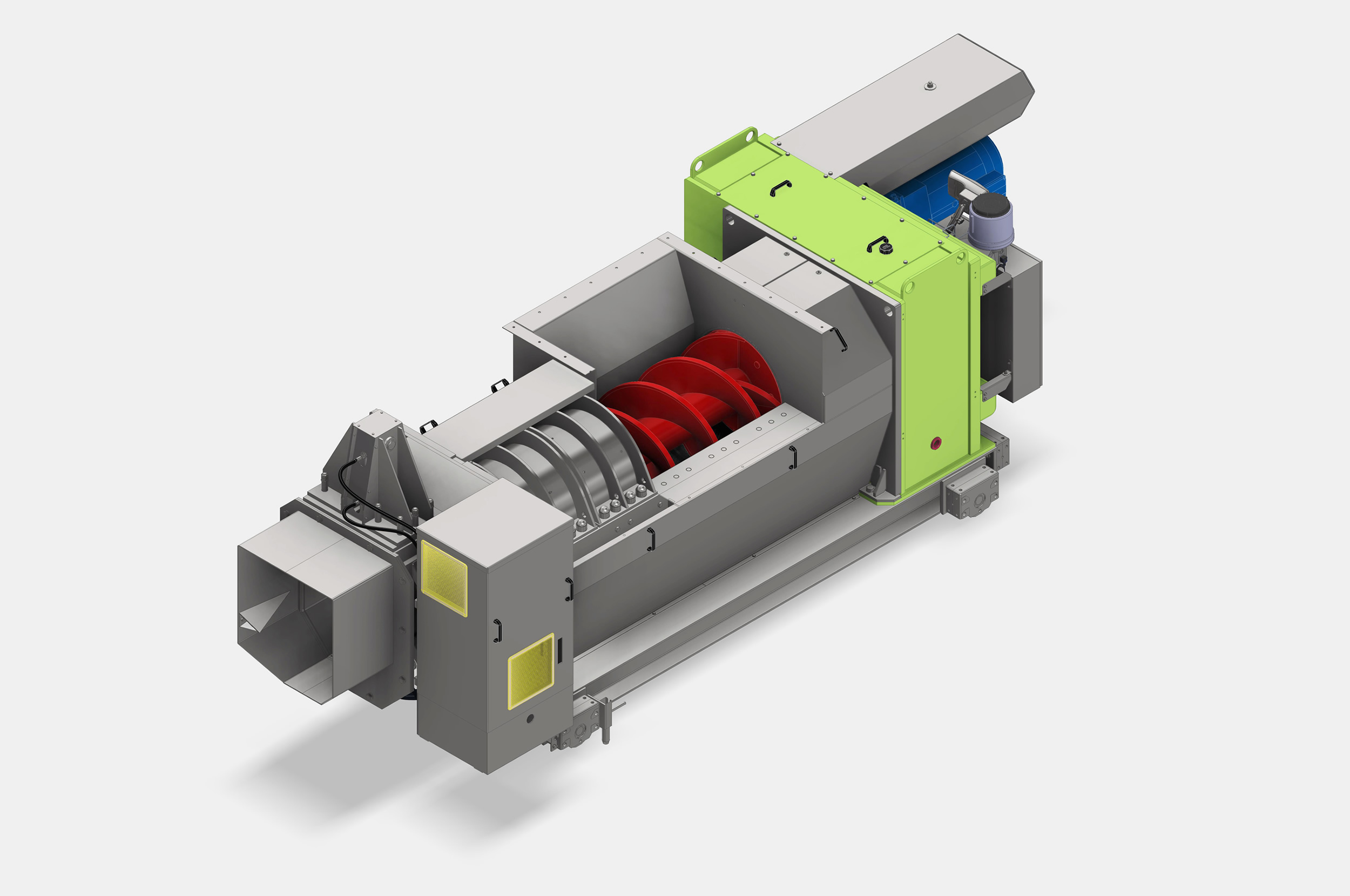

COMPAX R – Screw Compactor

High-Performance Lightweight Reject Dewatering Solution

[bws_pdfprint_pagebreak]

COMPAX R – Screw Compactor

High-Performance Lightweight Reject Dewatering Solution

Technology

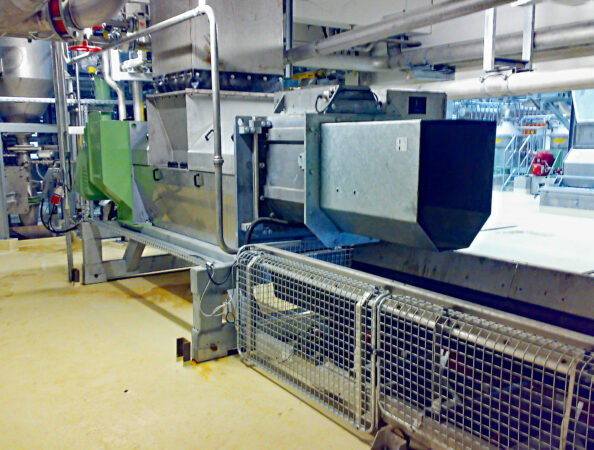

The Compax R is a sturdy high-performance screw press designed to dewater lightweight coarse rejects, reducing handling, transport and disposal costs for paper. Utilizing a slow-speed, high-torque screw, the reject gets first dewatered by means of gravity, and then pressed against the press nozzle flap. The high-pressure single flap hydraulic cylinder regulates the counter-pressure, maintaining dewatering and high dryness in all opersting condtions. A high performance fast micro controller optimizes operation with varying throughputs, by keeping constant torque and varialble screw speed minimizing wear and low maintenance.

Features

- The fast micro controller adjusts screw speed, torque, and press flap angle for optimized dryness up to 70%.

- High throughput capacity up to 50 BDMT/day Sturdy SEW gearmotor ensures high torque and durable performance.

- Wear-resistant components with fast slide-in/out installation for minimal downtime.

- Designed for 24/7 operation with low maintenance andeasy accessable components

- Refurbishment programs for screws, screens, and other wear parts, ensuring long-term sustainability.

Why to buy

- High return on investment through highest final discharge dryness.

- Low OPEX due to efficient and reliable performance.

- Minimal downtime with fast and easy maintenance access through slide in / out.

- High availability for 24/7 operation, achieving up to 10,000 continuous hours.

- Sustainable design with refurbishable components

- Industry-leading performance with over 500 proven installations worldwide.

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Dewatering and Pressing Lightweight Reject from Pulping.

- Pressing “Pre- Treated” Lightweight Reject from Drum Pulper.

- Pressing Lightweight Reject from De-Trashing / Sorting Drum.

- Dewatering and Pressing Lightweight Reject from Hole Screening.

See the following Products as well

- COMPAX CFX 80R

- COMPAX CFX- F 50, 60 for Fibrous Residual Material

- ECOMPAX ECX

- MBX- Belt Conveyors and MCS- Container Stations a.m.mm

- RSP Sludgeand Fiber Residual Screw Press RSP 1150,800, and 650

- Reject Pre-Dewatering with ELEPHANT Disk Thickener

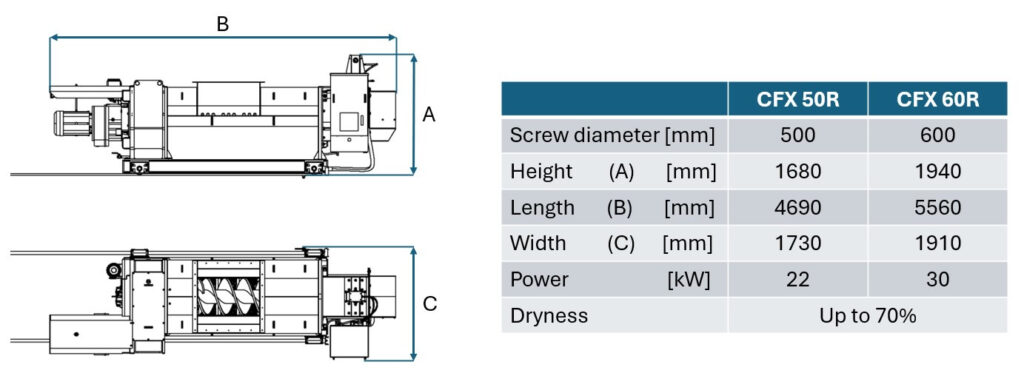

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]