Integrated Recycled

Paper Mill & WSR

Environmental Interfaces and Sustainability as Factor for Efficient Production and Profitability and the Integrated Recycled Paper Mill (IRPM)

Using recycled paper as raw material is state-of-the-art since decades.

Aspects as Sustainability and Environmental Interfaces have gained importance not only because Paper Producers are looking for better image, or have to follow tougher regulations, but also because ”Environmental Interfaces” of became a significant economical factor for the Paper Recycling respectively Paper making Process.

It can be expected, that in the future Environmental Aspects will gain further in importance, in some l geographical areas already discussions are going on to introduce sustainability ratings for paper mills and make them available for the public.

Labeling of paper products with special benchmarks for Sustainability and “Environmental Friendliness” will be a next step.

What do we need to consider as Environmental Interfaces

Beside the fact how new mills should conceptually be planned to minimize impacts of nature and environment at a minimum possible, these operational environmental interfaces are important:

- The use of resources water, energy, consumables, chemicals.

- The discharge of waste water, sludge, reject and residuals and

- The possible 2ndary reuse instead of final discharge and disposal

- Optimized logistics and transport of raw material, residuals and paper as product.

A challenge to be faced by engineers and managers is, that every paper mill has individual parameters and conditions, which will determine ROI and TCO of appropriate Environmental Technologies and Sustainability Management.

So in any case respective concepts need to be individually determined and engineered to achieve best economic advantages and better profitability.

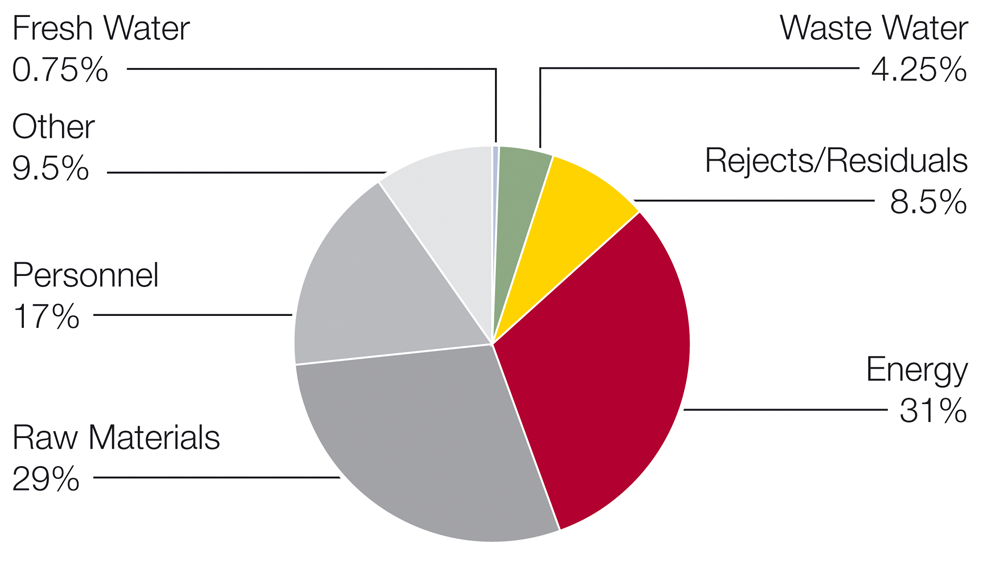

To understand the economic importance of Environmental Interfaces, a “typical North European Recycled Paper Mill” producing low weight packaging paper should be used as reference:

Production 1500-2000 t/d, raw material 100% Waste Paper, Yield 90%, In-house freshwater preparation, conventional effluent treatment.

Costs are shown as % of total operational production cost compared to other main cost factors:

Fresh Water 0,75 %, Waste Water 4,25 %, Reject & Residuals 8,50 %,

Energy 31 %, Raw Material 29%, Personal 17%, other 9,5%

Costs for Environmental Interfaces have an impact of 13,5 % of the total operational cost.

How to reduce cost and gain Profitability:

- Reduce freshwater consumption and waste water discharge by improved water reuse.

- Avoid disposal fees by 2ndary use of residuals e.g. generate replacement fuel

- Use own and 3rd parties replacement fuels for energy generation by incineration

- By changing to Anaerobic waste water treatment produce biogas and reduce energy consumption- and sludge disposal- cost of WWT

The Integrated Recycled Paper Mill (IRPM), Subsystems and Peripheral Systems

The Integrated Recycled Paper Mill (IRPM) is the evolution in further integrating peripheral processes to reduce Environmental Interfaces, safe Resources improve Operation and Profitability and gain Sustainability.

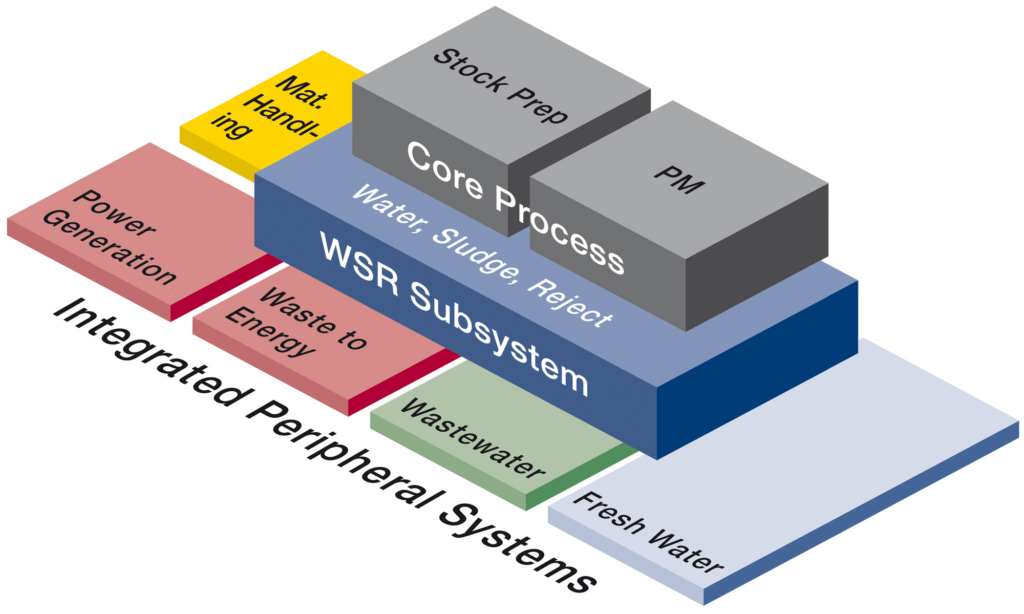

The IRPM Core Process

Stock Preparation and Paper Machine

The WSR Subsystem (Water, Sludge, Reject)

Consists of internal Water Loops around the paper machine and stock preparation which are directly connected and significant for the core process e.g. through selective clarification.

Pre- thickening and pressing of Sludge to remove non productive solids and contaminants allowing filtrate reuse.

The save handling of mostly discontinuous Reject streams which need to be separated, in 2ndary usable material streams and condioned, e.g. shredded and pressed to allow subsequent use as replacement fuel or similar.

The Integrated Peripheral Systems (IPS)

Which allow the continuous operation of the Core and WSR process, IPS modules are:

- Automated Material Handling of Wastepaper, bale opening and waste paper conditioning and feeding to the pulping process

- Freshwater Preparation from own or external source, Freshwater Management and conditioning for different process purposes as steam generation, sealing waters, chemical preparation and supply for high pressure felt showers.

- Wastewater Treatment considering pre- treatment, anaerobic biological treatment generating biogas, aerobic and secondary treatment with the possibility of clarified water recirculation.

- Chemical Preparation of process chemicals used e.g. in stock preparation, water treatment, dewatering and on the paper machine

- Fuel Storage and Conditioning to feed incineration with fuels form own residuals and/ or external supply as e.g. bio mass, replacement fuels, MRF or garbage.

- Power Generation e.g. by incineration