Reject and Residual Handling / Waste to Energy

MERI Environmental Solutions your Partner for Waste-to-Energy (WtE) in Recycled Fiber Paper Mills

Recycled fiber mills sort out / produce form the main raw material stream non-recyclable rejects & residuals (e.g. plastics, metals, stickies, grit) and large volumes of primary/secondary sludge from non-usable fiber and fillers and form the effluent treatment plant.

Instead of costly landfilling these waste streams, they are processed into a Refuse-Derived Fuel – RDF or Sludge-Derived Fuel – SDF.

The prepared fuel is then incinerated in dedicated boilers or co-fired in multi-fuel boilers, generating steam, heat, or electricity that can be used within the mill.

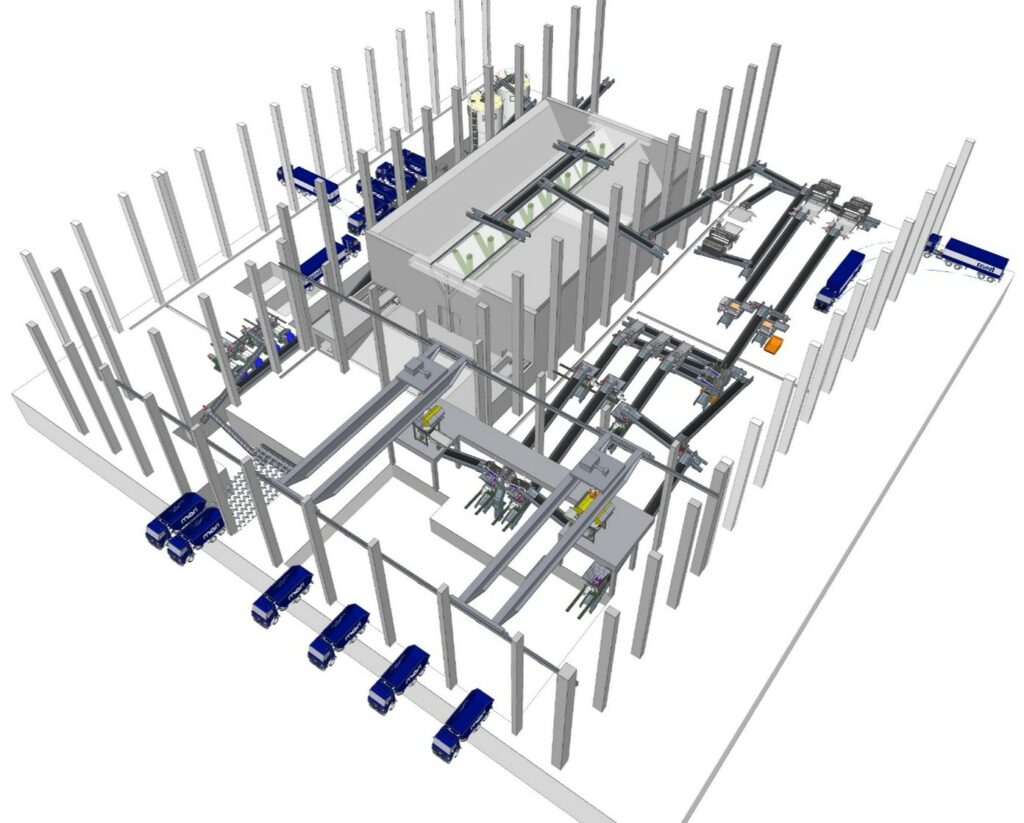

Depending on the paper mill and the respective stock preparation, in modern plants, Reject, Residuals and Sludge are already processed in WSR (Water-Sludge-Reject) Sub-Systems.

WSR Sub-Systems provide Rejects, Residuals and Sludge preconditioned, to be ready after Waste to Energy Treatment for Refuse-Derived Fuel – RDF use.

Waste to Energy Treatment integrates e.g. further shredding, sorting, Fe & AL removal, storage and controllable, constant material flow of conditioned Refuse-Derived Fuel – RDF to the Incineration Boiler.

This reduces disposal costs, replaces fossil fuels, and strengthens sustainability. With growing landfill restrictions and energy price volatility, WtE is both an economic opportunity and an environmental necessity for modern mills.

Meri Environmental Solutions can provide for Your mill / power plant customized solutions for:

- Internal de-central- and centralized- transport and storage of Rejects and Residuals and RDF.

- Conditioning of Rejects and Residuals according to requested Incineration Preconditions as:

- Internal and external (e.g. for trucks) reception bunkers and walking floors

- Shredding and sorting to target material size

- Detection and removal of bulk materials

- Elimination of Fe- and Non- Fe Metals (AL, etc.)

- Storage and conditioned fuel dosing

Advantages of Waste-to-Energy in Paper Mills

Environmental Advantages

- Reduces landfill volumes → cost savings, lower land use and methane emissions.

- Closes the loop by treating mill waste internally.

- Improves sustainability → supports ISO 14001, circular economy, and eco-label compliance.

Operational Advantages

- Reduces fossil fuel dependency → partial replacement of coal, oil, or natural gas.

- Stabilizes waste disposal → predictable, in-house solution for sludge and rejects.

- Volume reduction → >70% reduction in sludge/rejects mass after incineration.

Energy Advantages

- Sludge (after drying) has a calorific value of ~2,000–3,500 kcal/kg.

- Rejects (plastics, stickies) have higher CV, ~8,000–14,000 kcal/kg.

- When blended → a stable derived fuel with usable energy for the mill.

Economic Advantages of Waste-to-Energy

Cost Savings

Landfill Avoidance

- Landfilling sludge & rejects is costly and increasingly restricted.

- WtE eliminates tipping fees and transport costs.

Fuel Substitution

- Offsets coal/gas purchases.

- Example: If 1 ton of sludge/reject fuel replaces ~0.3–0.5 tons of coal, significant annual savings.

Energy Self-Sufficiency

- Reduces exposure to volatile energy markets.

- Ensures continuous supply of steam/power for paper drying.

CAPEX & OPEX

- CAPEX → Incinerators, dryers, shredders, fuel preparation units, emission control systems.

- OPEX → Maintenance, labor, electricity for drying, consumables (lime, urea for flue gas cleaning).

- Typically, payback period = 3–6 years, depending on mill size, waste volume, and local fuel/landfill costs.

Possible By-product Revenue

- Ash may be used in cement or construction industries.

- Carbon credits possible under renewable energy and circular economy schemes.