BASIC FLOAT – Dissolved Air Flotation (DAF) Clarifier

[bws_pdfprint_pagebreak]

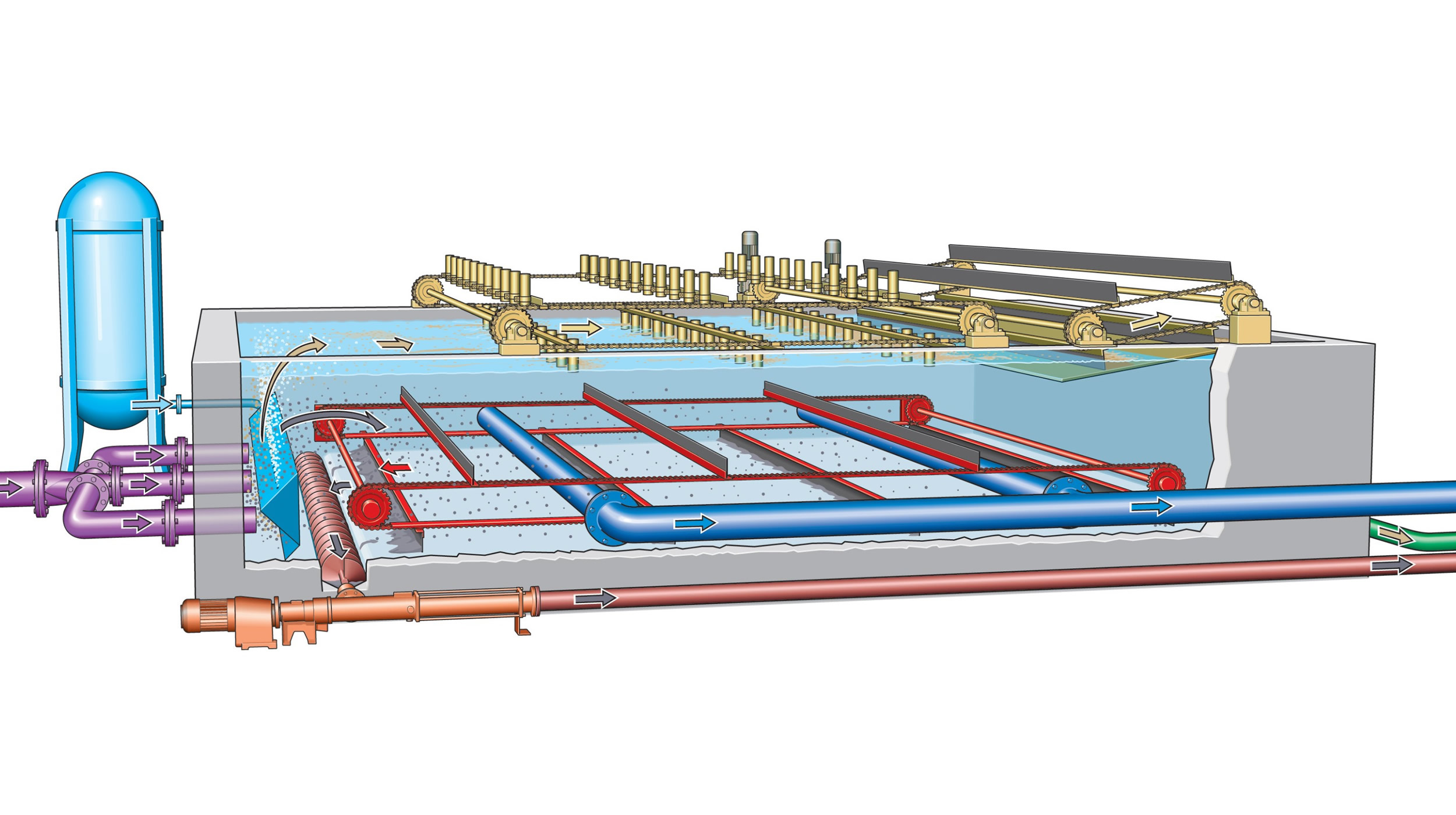

BASIC FLOAT Dissolved Air Flotation (DAF) Clarifier

Technology

The Basic Float is a conservative standard Dissolved Air Flotation (DAF) Clarifier for which the tank can be executed in concrete or steel.

A portion of the treated stream is saturated with pressurized air in a saturator (dissolving vessel). When that saturated stream is returned and released to the flotation tank at atmospheric pressure, the dissolved air comes out as a cloud of fine micro-bubbles. Those bubbles attach to flocs (coagulated/flocculated solids) and lift them to the surface where they form a sludge blanket. Floated sludge is removed by a surface paddle/scraper while any heavier settleable solids are removed by a bottom scraper to a sludge hopper.

Features

- Rectangular concrete or fabricated steel tank.

- Typical compartments (in flow order): influent inlet/flocculation (sometimes external rapid mix + floc), DAF flotation zone, surface floated sludge collection by paddle scraper

- Length-to-width ratio depending on layout and installation space

- Diffused inlet baffle and distributor header to reduce velocity and distribute flow uniformly across the cell width

- Recycle stream is introduced to the flotation tank through a pressure-reduction valve and a fine-bubble distribution

- The slow-speed rotating arm with paddle blades/flights gently skims the floating sludge toward longitudinal sludge troughs/hoppers located on the tank end

- Collected surface floated sludge drops into a collection trough and is pumped (sludge pump) or gravity-conveyed to a sludge holding tank or dewatering unit

- Bottom scraper executed as continuous chain scraper or rake running near the tank bottom to collect any heavier, settleable sludge and to prevent dead zones

- The bottom scraper sweep solids to a central longitudinal hopper or to end hoppers where a sludge pump (submersible or dry pit) evacuates sludge

Why to buy

- Classical Dissolved Air Flotation clarifier for execution with concrete or steel tank

- Cost Effective Equipment if large installation space is available

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Water Clarification applications for Paper and other Industries.

- Closing of water loops and reduction of freshwater consumption

- Clarification of primary and secondary mill effluent

- Other industrial applications for food, oil, or chemical industry – please ask for details

See the following Products as well

- Universal Dissolving System

- Circular Sedimentation Tank

- Tauro TAL

- Elephant

- Dinoscreen

- LimeTrap

- DeltaPurge

- Vulcano

- GyroSand

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]