meri BioSulph Biological Biogas Desulphurization

[bws_pdfprint_pagebreak]

meri BioSulph Biological Biogas Desulphurization

Technology

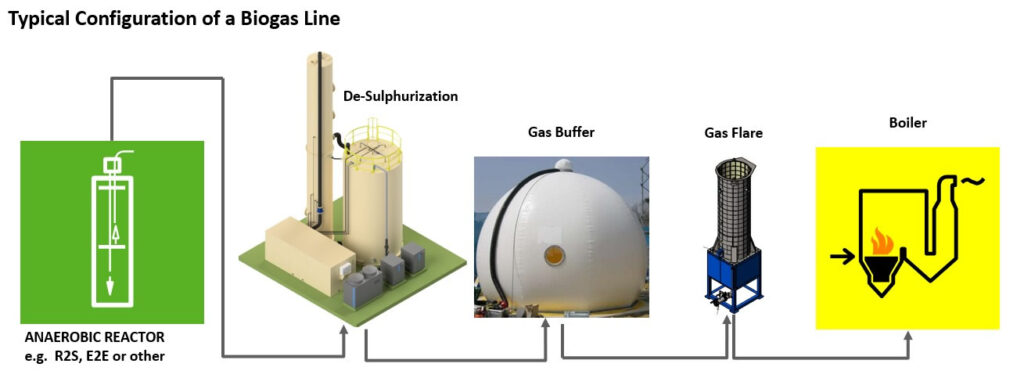

Anaerobic Reactors are today state of the art in effluent treatment for Recycled paper Mills and other Industrial Productions with high Effluent Loads (e.g. Breweries, Food Production and others). Key benefit of Anaerobic Waste Water Treatment is the Production of Biogas.

Raw biogas from Anaerobic Reactors in Effluent Treatment contains not only methane (CH₄) and CO₂, but also hydrogen sulfide (H₂S).

H₂S is toxic, corrosive, and harmful to gas engines/pipelines, therefore, it must be removed before using or upgrading biogas.

Biological methods are preferred over chemical scrubbing because they are cost-effective and environmentally friendly.

The Process comprises 2 Process Stages:

Washing in which the raw biogas is counter washed through a sprayed liquid phase (recycled water or a weakly alkaline solution). H₂S is much more soluble in water than CH₄ or CO₂, so it preferentially dissolves (H₂S (gas) → H₂S (dissolved) in the washing liquid (In slightly alkaline conditions, dissolved H₂S can partly dissociate), as a result the Biogas leaving the scrubber has significantly reduced H₂S content.

The washing liquid now contains dissolved sulfides (H₂S, HS⁻, sometimes S²⁻).

The sulfide-loaded washing liquid is sent to an aerobic bioreactor containing sulfur-oxidising bacteria (SOB), which uses oxygen as an electron acceptor to oxidise sulfides.

a) Partial oxidation to elemental sulfur (S⁰):

HS−+½O2→S0+OH−HS⁻ + ½O₂ → S⁰ + OH⁻HS−+½O2→S0+OH−

b) Further oxidation to sulfate (SO₄²⁻):

S0+1½O2+H2O→SO42−+2H+S⁰ + 1½O₂ + H₂O → SO₄²⁻ + 2H⁺S0+1½O2+H2O→SO42−+2H+

Depending on process control (oxygen availability, pH), the system can be tuned to favor elemental sulfur recovery (valuable product) or full sulfate mineralization

The washing liquid is regenerated (sulfides removed), so it can be reused for the next biogas washing cycle, and the end products are elemental sulfur (solid, can be harvested) or sulfate in solution (may be discharged with wastewater).

Features

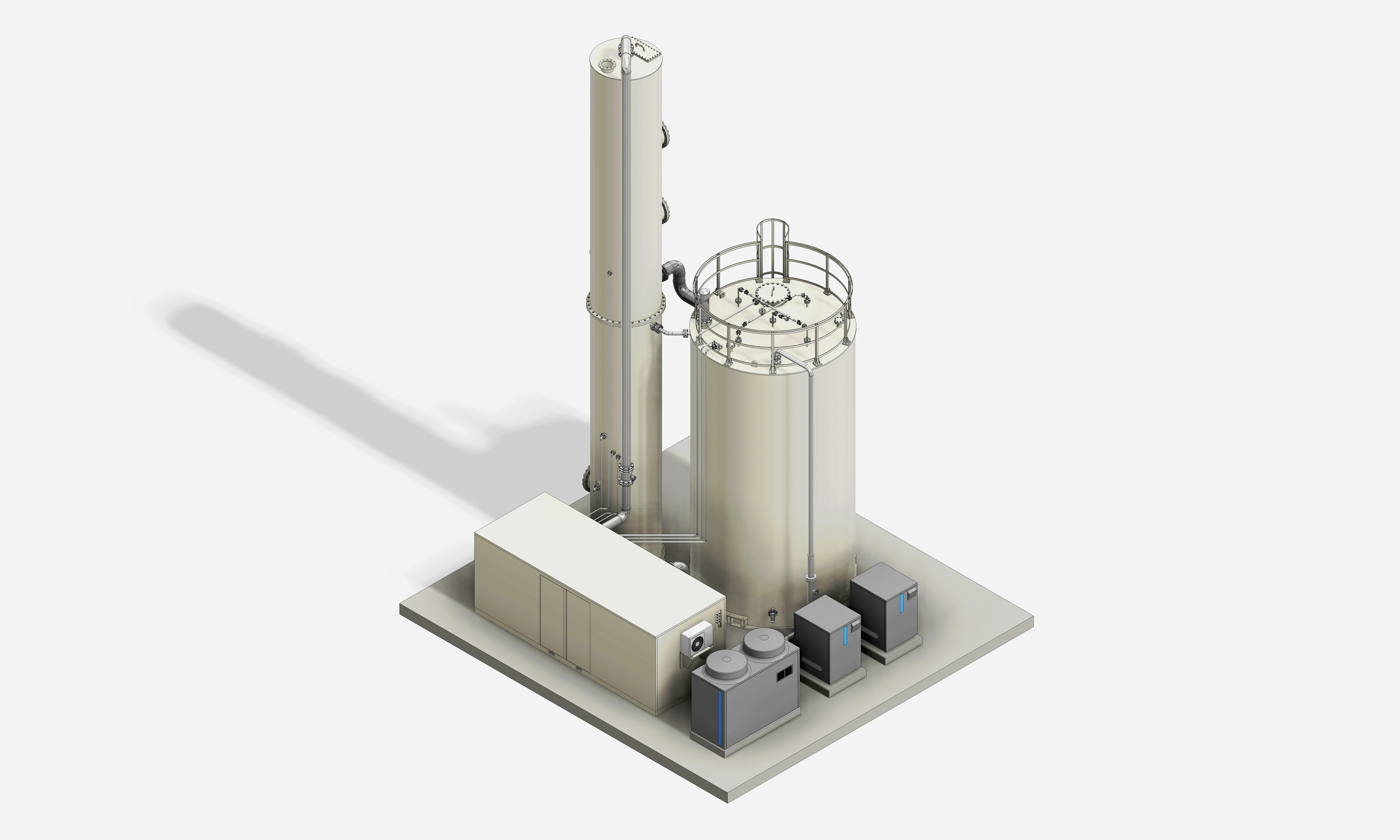

- Compact “all in one – 2 stage Desulfurization Process” with Biogas Scrubbing and sulfur oxidizing by biological bacteria in aerobic bioreactor.

- Modular design allows adaptation to different Process Characteristics and Capacities

- High Efficient Gas Scrubbing according to counterflow principal

- Efficient Compact Aerobic Bioreactor, easy to control, to reach elemental sulfur recovery (valuable product) or full sulfate mineralization.

Why to buy

- Compact pre-installed meri BioSulph Biological Biogas Desulphurization with perfect integration to meri R2s, E2E or other Anaerobic Reactors.

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Desulphurization for Biogas Streams out of Anerobic Waste Water Treatment with R2s, E2E or other Anaerobic Reactors

See the following Products as well

- R2S Anaerobic Reactor

- E2E Anaerobic Reactor Series

- MERI Flare and Gas Buffers

- Circular Sedimentation Tank

- LimeTrap

- Tauro TAL

- DeltaPurge

- Vulcano

- GyroSand

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]