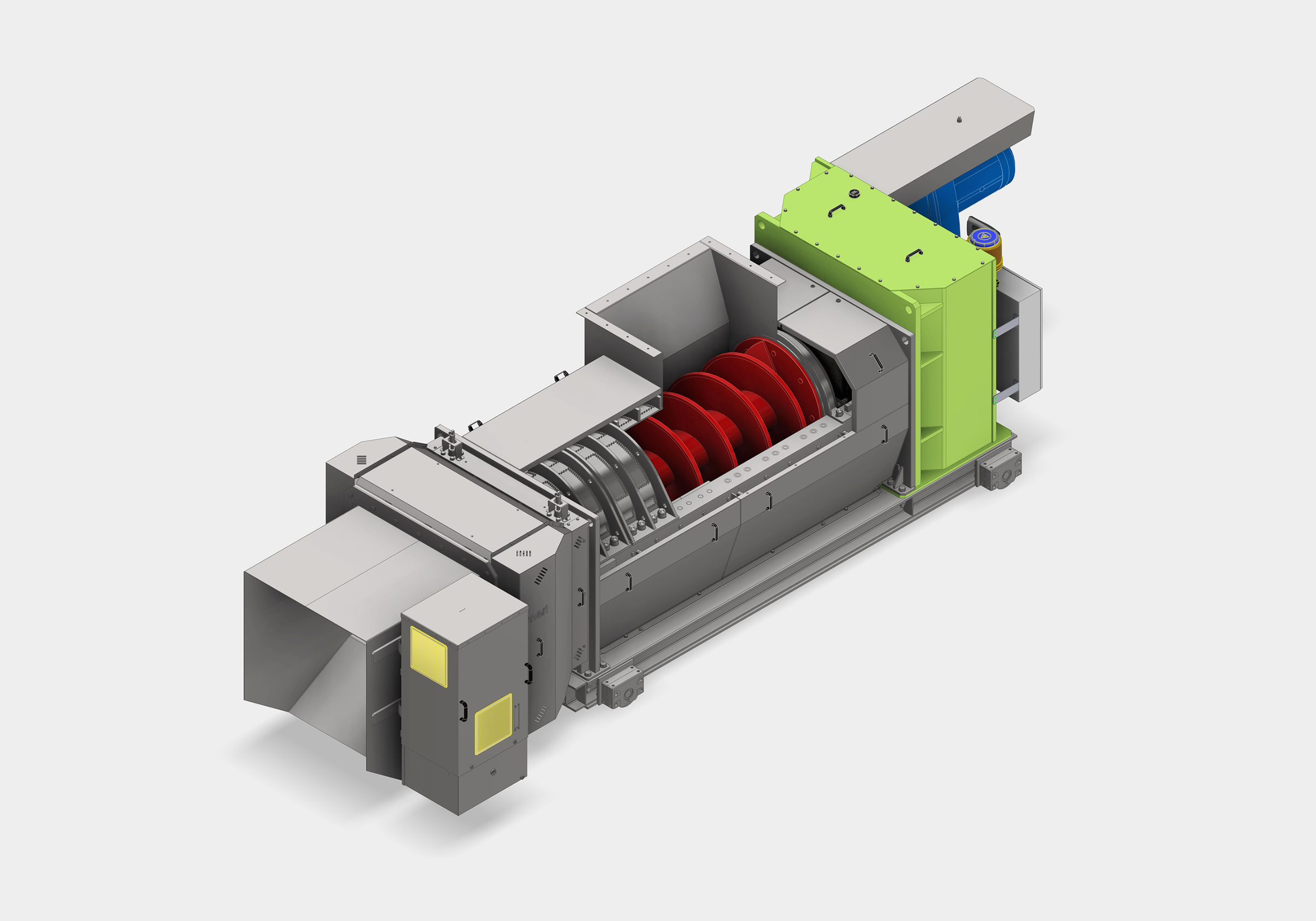

COMPAX CFX-F 80 – Screw Compactor

The Most Powerful Compactor Available On The Market

[bws_pdfprint_pagebreak]

COMPAX CFX-F 80 – Screw Compactor

The Most Powerful Compactor Available On The Market

Technology

The COMPAX CFX-F 80 dewaters all fine and fibrous lightweight reject/sludge from the stock preparation area in paper mills. Utilizing a slow-speed, high-torque screw, it presses residuals through a tube screen pipe against a hydraulically operated twin flap, creating high counter pressure. This design efficiently removes surface water through half screens, achieving up to 60% dryness (TS). A high-performance fast micro controller dynamically adjusts parameters such as screw speed and press flap angle for optimized performance with varying residual inputs. Operating 24/7 with the lowest possible and fast maintenance, it delivers reliable and cost-effective dewatering.

Features

- Left- right side Twin Press Flaps secure uniform dewatering, higher dryness and avoids Press Screw bending.

- Intelligent monitoring adjusts throughput and ensures optimal pressing results at low energy consumption.

- High throughput capacity of over 50 BDMT/d with dryness up to 60% TS.

- Durable SEW gearmotor, hydraulic twin press flaps, and modular screw design for high torque and easy part replacement.

- Wear-resistant, low-maintenance design ensures reliability and long operational hours.

- Slide-in/out configuration simplifies maintenance and minimizes downtime. Comprehensive refurbishment programs for screws, screens, and other components.

Why to buy

- Market leader with over 500 installations worldwide.

- Next-gen intelligent controls enhance performance and minimize wear.

- 24/7 automatic operation with high throughput.

- Achieves up to 60% dryness and processes over 50 BDMT/day for unmatched efficiency, reducing transport and disposal costs.

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Dewatering of Fibrous Reject mixtures

- from Cleaning & Fine Screening

- from Fine Screening

- from LC-Cleaner Rejects

See the following Products as well

- COMPAX CFX- F 50, 60 for Fibrous Residual Material.

- COMPAX CFX 80R.

- COMPAX CFX 60R and CFX 50R.

- ECOMPAX ECX.

- MBX- Belt Conveyors and MCS- Container Stations a.m.mm.

- RSP Sludge and Fiber Residual Screw Press RSP 115,80, and 65.

- Reject Pre-Dewatering with ELEPHANT Disk Thickener.

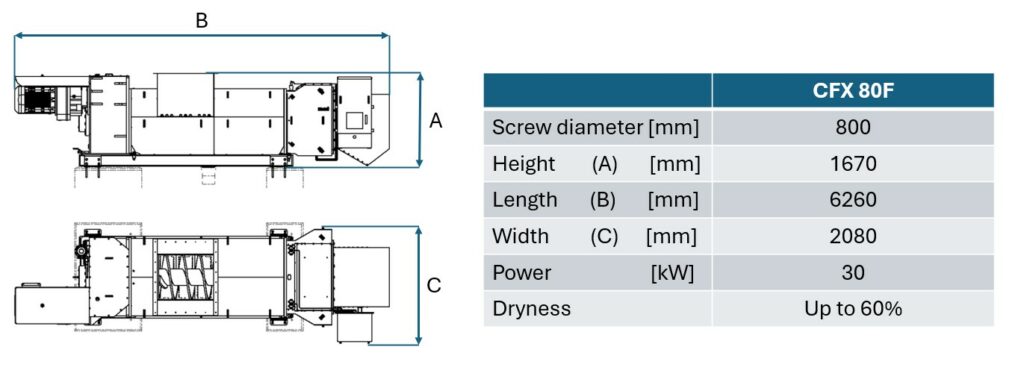

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]