DINOSCREEN – keep your U-Drain Channels clean

[bws_pdfprint_pagebreak]

DINOSCREEN – keep your U-Drain Channels clean

Technology

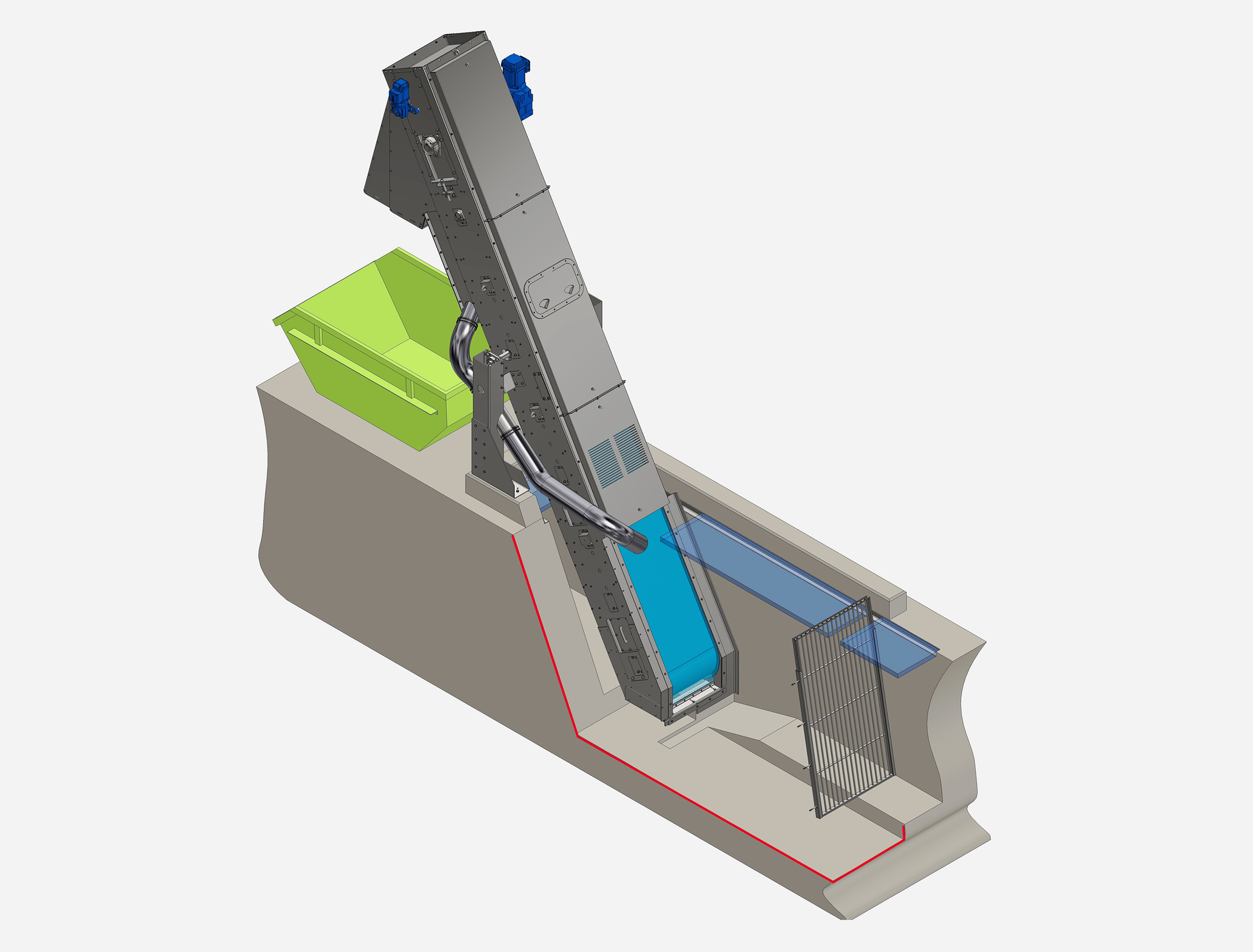

In existing and new green field Paper Mills spilling- and waste waters are collected in U-Drain- / Sewer Channels. Very often Coarse Contaminants such as plastic foils, wood residuals, polystyrol and many others accumulate in these Sewer Channels and consequently plug pumps and discharge pipes.

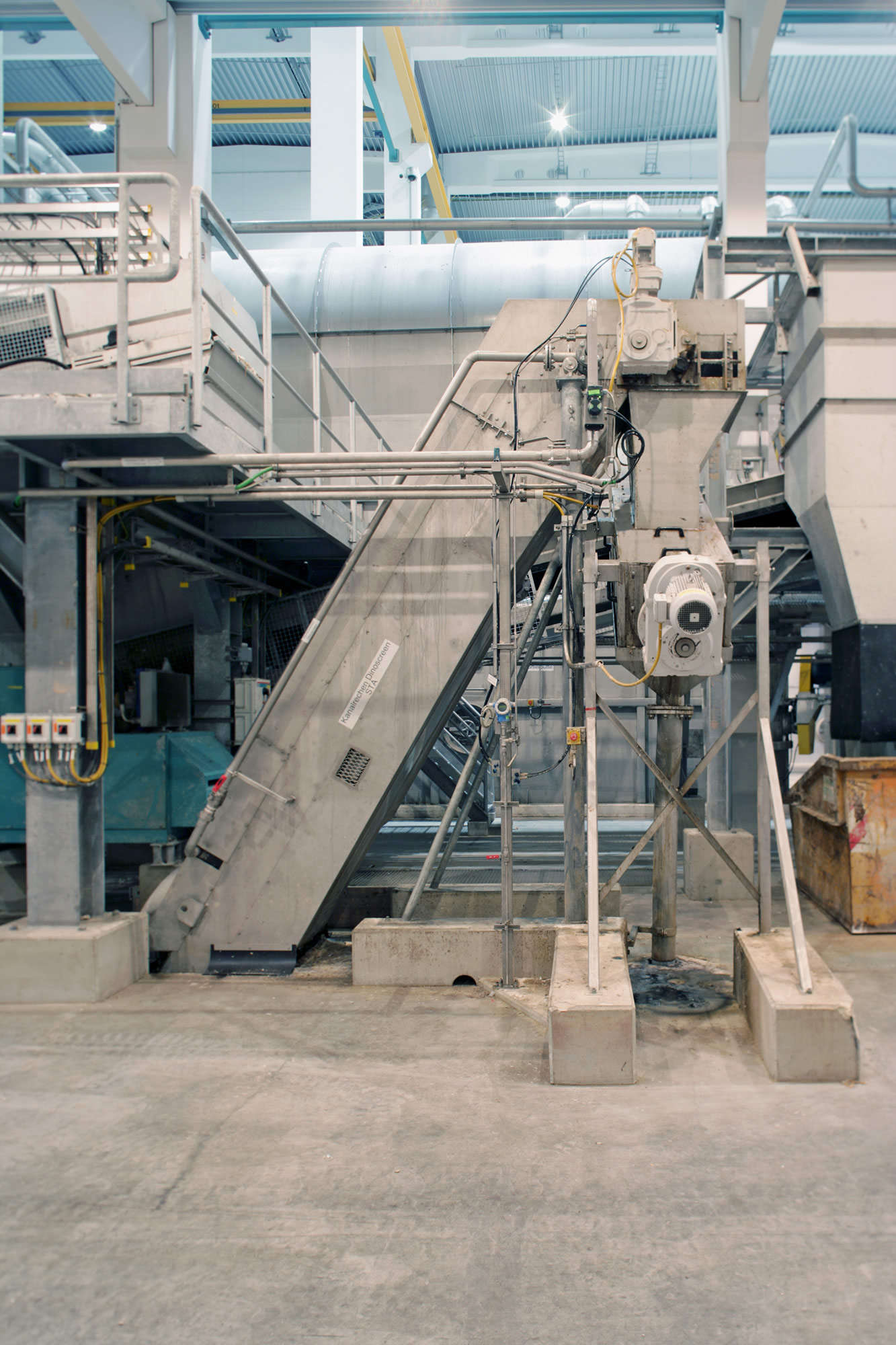

The DINOSCREEN is a travelling screen designed for continuous operation, which is submerged in the Sewer Channel. For filtering and back hold of Contaminants an upwards travelling screen chain is used, this 30 degrees inclined Screen Chain consists of single fiber reinforced composite Rake Fingers with 3 or 6 mm vertical gap in between.

Filtered contaminant material is so with in continuous operation slowly conveyed out of the U-Drain water stream and discharged to a container for disposal.

The upward moving Screen Chain is cleaned by spray Nozzles and a rotating brush element.

The DINOSCREEN Equipment is hinged and can be lifted out of the “U- Drain operating position” within minutes for Inspection or Maintenance.

Features

- Continuous slow operating Screen Chain to clean U-Drain- / Sewer Channels, consisting Rake Fingers with 3 or 6 mm gap

- Body and mechanics built fully in Stainless Steel; fiber reinforced composite Rake Fingers

- Special hinged Design allows to lift DINOSCREEN out of the “U- Drain operating position” without crane

- Designed for deep U-Drain- / Sewer Channels and high Volume through put

Why to buy

- Market Leading Travelling Screen with 150 Industry Installations WW

- Keeps U-Drain- / Sewer Channels clean and secures reliable sewer pump operation

- Easy Access und maintenance thanks to hinged Design

- Simple, Energy Efficient low OPEX

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Detrashing and removal of Coarse Contaminants from U-Drain- / Sewer Channels

- Contaminant protection and removal for Fresh Water intake from Surface Water as Rivers and Lakes

See the following Products as well

- Elephant Filter

- MSC Screw Conveyors

- MBX Belt Conveyors and Container Stations

- COMPAX CFX and ECOMPAX ECX Trash and Reject compactors

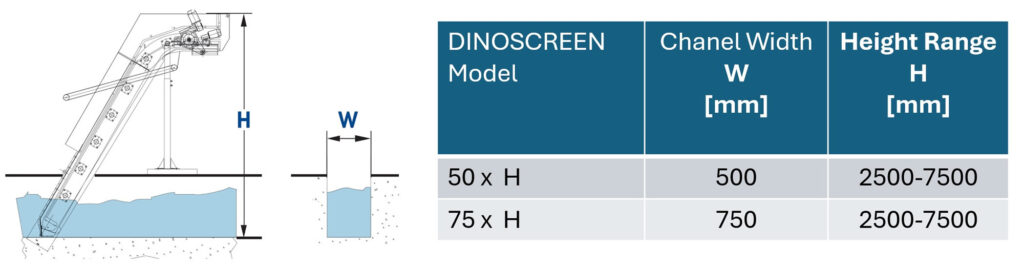

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]