E2E ANAEROBIC REACTOR

[bws_pdfprint_pagebreak]

R2S ANAEROBIC REACTOR

Technology

The E2E Anaerobic Reactor is a fluidized bed reactor specifically designed for the anaerobic treatment of industrial wastewater. The E2E transforms organic waste loads in the wastewater anaerobically and produces biogas. Active granular biosludge pellets, consisting of anaerobic microorganisms, have contact and effective interaction with wastewater due to extensive mixing regulated by upflow velocity via external flow recirculation. This surface exchange provides optimal access to degradable contaminants and nutrients for the microorganism in order to remove COD Load.

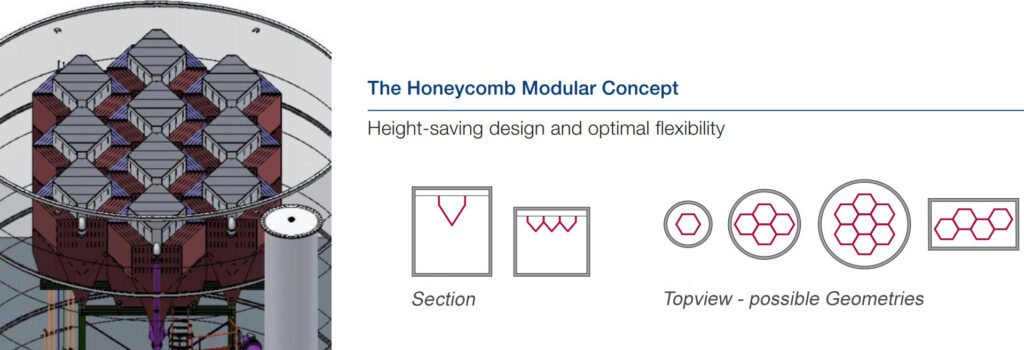

The E2E design provides efficient biogas separation and reliable pellet retention through 3-phase hexagonal “honeycomb” separators supplied in single modules.

The reactor is fully gas tight to prevent odor emissions, corrosion and minimizes sulfur deposits, ensuring long-term reliability and low-maintenance operation.

Features

- Fluidized bed reactor designed for the anaerobic treatment of industrial wastewater

- Innovative settler hexagonal “honeycomb” design for modular installation in existing or new tanks, allowing a wide range of wastewater flows and COD concentrations.

- handling a wide range of wastewater concentrations

- Robust and easy-to-maintain distribution system, cost-saving flat-bottom tank design

- Adjustable up-flow velocity through external clarified flow re-circulation

- Simple assembly of hexagonal “honeycomb” three-phase separators on existing or new support structure, easy installation and piping

- Biogas collected in the reactor headspace and transported to the gas line

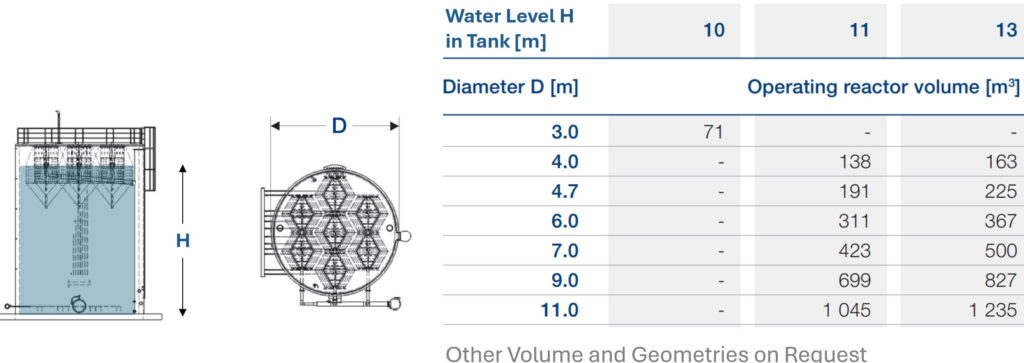

- Proven reactor sizes, suitable for varying industrial applications

Why to buy

- Cost-effective design with higher active reactor volumes, reducing the need for larger, more expensive tanks

- Hexagonal “honeycomb” settler design can be installed in existing tank geometries

- Simple, reliable operation and low maintenance

- Efficient biogas collection and transport system for optimized energy recovery

- Flexible design options with concrete, welded and bolted tank configurations

- Proven reliability and efficiency, supported by a range of available reactor sizes

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Anaerobic treatment of industrial wastewater, including paper production (DIP, Virgin), food, and beverage industries (brewery, dairy, sugar, etc.)

- Biogas production effluents with high COD loads

- Efficient sludge management and sludge growth

See the following Products as well

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]