EDDY CURRENT SORTER (ECS) for removal of non-ferrous metal of shredded Reject & Residual streams

[bws_pdfprint_pagebreak]

EDDY CURRENT SORTER (ECS)

Technology

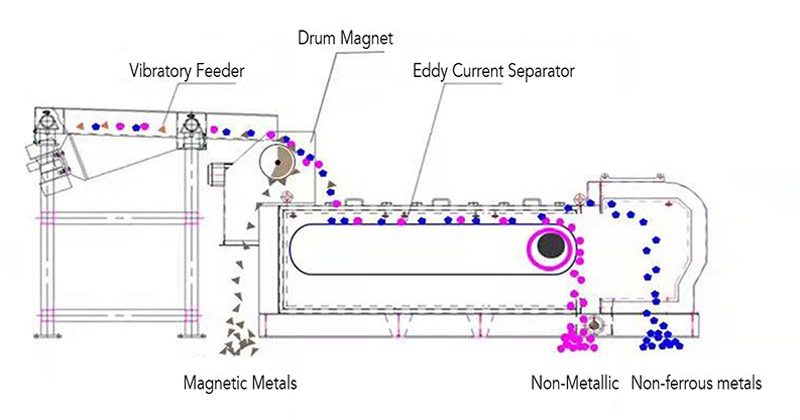

The Eddy Current Sorter (ECS) is a non-ferrous metal separation machine. It uses the principle of electromagnetic induction it is often combined with a first stage magnetic ferrous metal separation. Inside the machine, a fast-rotating magnetic rotor is mounted at the end of a conveyor belt. As waste material is carried over the rotor, the rapidly changing magnetic field induces eddy currents in conductive (non-ferrous) metals such as aluminum, copper, brass, zinc, etc.

These eddy currents create their own magnetic field, which produces a repelling force, as a result, non-ferrous metals are “thrown” forward into a separate trajectory, while non-metallic material (plastics, glass, organics) falls normally.

Features

Modern ECS units offer several advanced technical features:

- Feed via vibrating conveyor to spread material into a thin, uniform layer across the full width of the ECS belt, reduces clumps and overlapping pieces (which could shield metals and lower recovery efficiency)

- Pre-sorting of Ferrous Metals -since the ECS works only on non-ferrous metals, any ferrous metals (iron, steel) must be removed beforehand by magnetic head pulley, the conveyor belt passes over this magnetic roll, the magnetic field attracts ferrous metals (steel, iron, tinplate, etc.) and the conveyor belt itself carries the ferrous items past the normal discharge point

- Neodymium rare-earth magnets for strong magnetic fields

- Belt conveyor with adjustable speed for controlling throw distance

- Split housing for easy maintenance and rotor replacement

- Robust construction to withstand abrasive waste streams

- Adjustable splitter plates to fine-tune separation efficiency

Why to buy

High-value recovery – Extracts aluminum, copper, and other non-ferrous metals that can be sold.

- Revenue generation – Pays for itself through recovered metals

- Waste stream purification – Produces cleaner non-metal fractions (plastic, RDF, glass, aggregates)

- Low operating cost – Only needs electricity for belt and rotor motors

- High throughput – Can process several tons per hour, scalable for plant size

- Environmentally beneficial – Diverts recyclable metals from landfill or incineration

- Proven technology – Widely adopted in recycling, reliable with predictable ROI

Typical & Proven Process

- recovering aluminum cans, foils, and non-ferrous scrap from Reject and Incineration Derived Fuels Streams, to avoid AL corrosion in incineration vessels

- Recycling Plants (MRFs): improving metal recovery from mixed recyclables.

- Electronic Waste (WEEE): extracting valuable non-ferrous metals (copper, aluminum).

See the following Products as well

- Lion Shredder

- Finger Sorter

- Meri Belt Conveyor

- COMPAX screw compactor Series

- ECOMPAX and Minipress

- MSC Meri Screw Conveyors

- RSP Sludge Press

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]