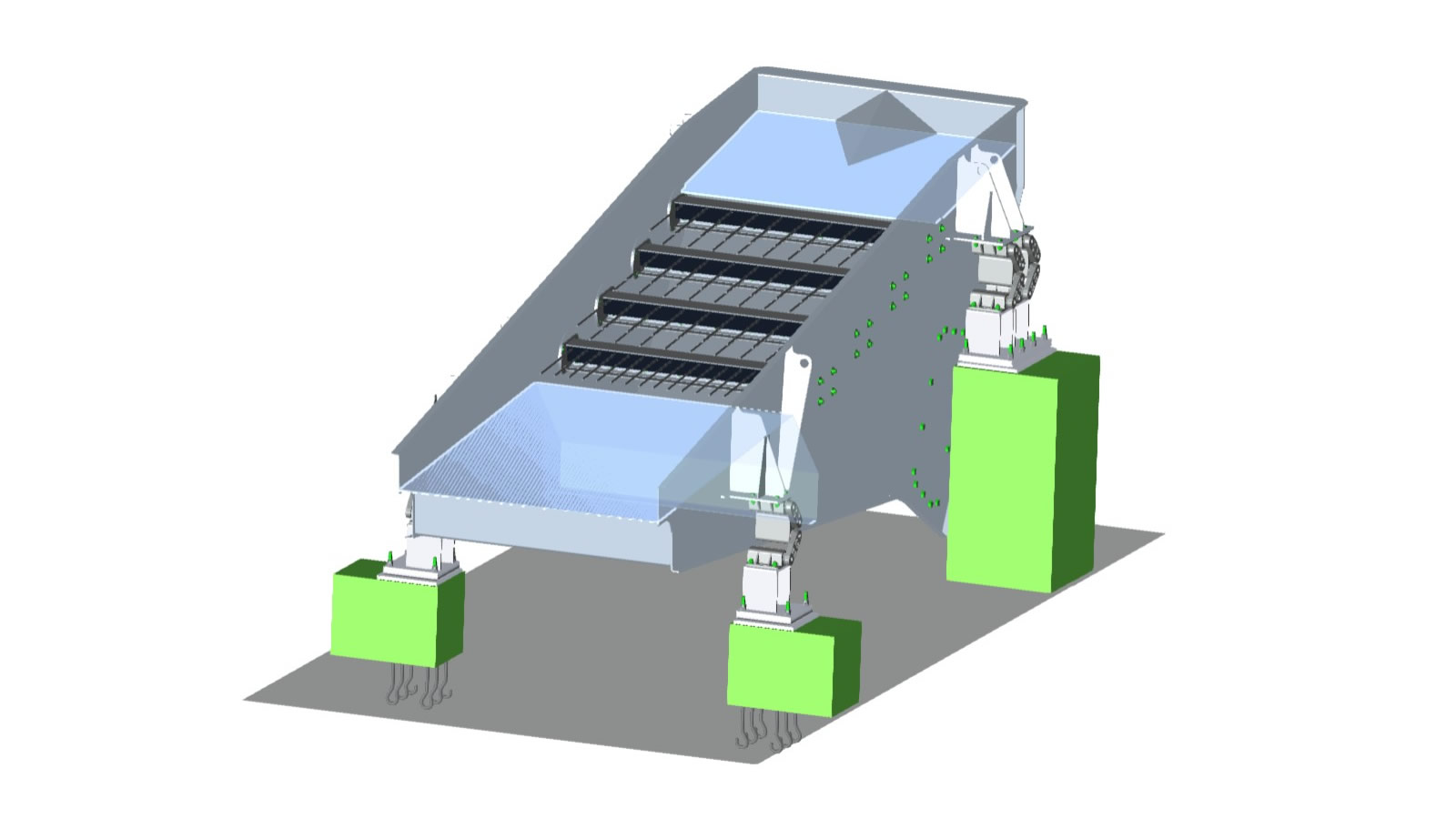

VIBRATING FINGER SORTER

For classification of shredded Reject & Residual streams

[bws_pdfprint_pagebreak]

VIBRATING FINGER SORTER

For classification of shredded Reject & Residual streams

Technology

The VIBRATING FINGER SORTER is essentially a vibrating deck / conveying trough with staggered, interlaced metal “fingers” instead of a flat screen surface.

The Working Principle: Material is fed onto the vibrating deck / conveying trough which vibrates with controlled frequency and amplitude and so with conveys the loaded Reject Materials. The interlaced fingers create self-cleaning openings that allow smaller fractions to fall through. Larger, bulky, or flat items (e.g. plastic films, larger Reject agglomerations) are forwarded (or rewarded) to further (or previous) Shredding Stages.

Features

- Key Difference vs. Conventional Screening are, no flat mesh to clog Fingers flex and vibrate, preventing jamming or wrapping and Handle irregular, wet, or sticky materials better

- Self-cleaning finger deck (prevents clogging, low maintenance)

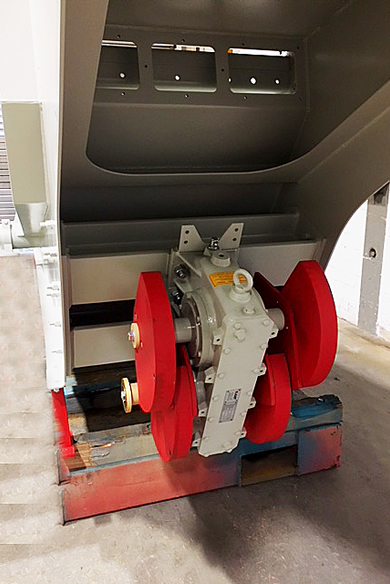

- Adjustable vibration parameters (frequency & amplitude for tuning performance)

- Heavy-duty construction (handles abrasive and high-volume waste)

- Scalping ability (removes fines early, reducing wear on downstream machines)

- Customizable finger spacing (to define cut size, e.g., 40 mm, 60 mm, etc.)

- Modular decks / conveying troughs (easy replacement and flexible configurations)

- Low power consumption compared to rotary trommels

- Capability to handle wet, sticky, or irregular material without downtime

Why to buy

- High uptime – Self-cleaning design reduces blockages, unlike trommels or mesh screens

- Versatility – Handles mixed waste streams, including wet and sticky fractions

- Improved downstream efficiency – Removes fines and contaminants early, extending life of optical sorters, air classifiers, and conveyors

- Low operating costs – Less energy and maintenance compared to other screening technologies

- Scalability – Modular design allows customization for throughput

- Durability – Robust build tolerates heavy-duty waste streams (C&D, bulky waste)

- Cleaner product streams – Better separation of fines vs. oversize improves material recovery rates

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Secure Max Size of Shredded and Sorted Reject Materials (gate)

- Sort Oversize Reject Materials to be recycled back to previous Shredding Stage

- Preparing feed for optical sorters, eddy current separators, and air classifiers

- Front-end screening of mixed Rejects and Recyclables

- Protecting downstream equipment (e.g., optical sorters) from contamination

See the following Products as well

- Lion Shredder

- Eddy Current

- Meri Belt Conveyor

- COMPAX screw compactor Series

- ECOMPAX and Minipress

- MSC Meri Screw Conveyors

- RSP Sludge and Residual Press

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]