GAS FLARE and GAS BUFFER – key process elements for Biogas Handling

[bws_pdfprint_pagebreak]

GAS FLARE and GAS BUFFER – key process elements for Biogas Handling

Technology

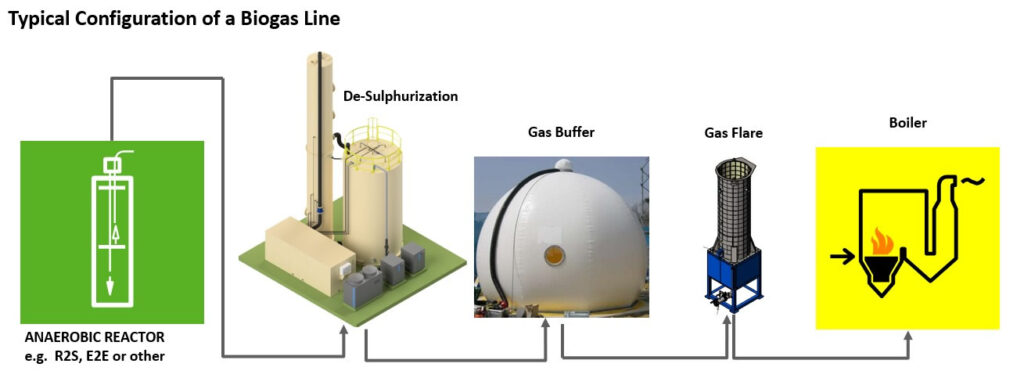

Anaerobic Reactors are today state of the art in effluent treatment for Recycled paper Mills and other Industrial Productions with high Effluent Loads (e.g. Breweries, Food Production and others). Key benefit of Anaerobic Waste Water Treatment is the Production of Biogas, which is not generated at a perfectly steady rate, nor is demand (e.g., CHP or boiler) always constant. Therefore a biogas buffer tank provides temporary storage to equalize fluctuations in production and consumption and maintains stable gas pressure.

In order to prevent emergency venting due to Biogas overproduction, and especially when the Biogas Buffer storage capacity has reached the maximum, a controlled Flare safely burns the surplus gas, and acts so with as safety device and it must not be vented directly to the atmosphere (methane is a potent greenhouse gas).

Features

- Compact Biogas Buffer provides pressure regulation as Flexible Membrane Gas Holder, with “Double Membrane Domes” mounted on a flat concrete foundation.

- Automatic starting Biogas Flare with adapted gas burning capacity to burn surplus Biogas and acts so with as safety device up to the maximum gas flow at full operation of Anaerobic Reactor.

- Flare operates as Fully Cover Flare to avoid Flare Light disturbance and better heat control

Why to buy

- Balancing of Gas Production & Consumption – Biogas production is continuous (microbes never stop working) – Consumption (CHP, boiler, grid injection) is variable

- Provides a steady gas pressure to Incineration Power Plant

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Biogas Storage and Excess Biogas Burning

See the following Products as well

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]