LION SHREDDER

[bws_pdfprint_pagebreak]

LION SHREDDER

Technology

The LION is a high-performance shredder developed for shredding coarse materials, including pulper rejects and other residuals. The Shredder operates with two slow counter-rotating shafts, enabling up to 8.000 hours of continuous operation before requiring knife set replacement and outperforming traditional shredders in both operational costs (OPEX) as well as in performance.

The specially designed drop-forged, precision-machined knives offer superior cutting performance, an extended lifespan, and reduced maintenance requirements. Each shredder shaft is independently powered by a dedicated hydraulic drive, ensuring optimal performance and precise torque control. A dedicated high-speed microcontroller operates and optimizes continuously the Shredder cutting performance and protects the equipment by immediate torque adjustment in the case of blockage or overload.

The LION is the ultimate solution for both coarse and fine shredding, offering exceptional strength as well as consistently monitored performance to maximize uptime and minimize operating costs.

For small throughputs, we can also supply electric instead of hydraulic drives on request.

Features

- High-quality cast iron housing designed and optimized by using FEA

- Hot-forged hardened knifes that can be resharpened

- Dual-shaft shredder with one independent drive for each cutting shaft

- Speed of each cutting shaft is adjusted independently by microcontroller to secure best throughput and cutting performance by intermediate torque control

- Smart control system that ensures a low wear shredding sequence

- Fast reaction time in case of blockage or overload

- Parameters monitoring control system allows predictive maintenance

- Wear-resistant and low maintenance design

- Slide-In/Out Installation for easy and fast maintenance access

- Exchange, refurbishment and service programs for spare and wear parts

Why to buy

- High throughput capacity, capable of handling large quantities of material efficiently

- Superior hot-forged knife quality results in low operational cost (OPEX)

- Safe and reliable operation with very low downtime

- Special pre-tensioning system for the knife set requires minimal maintenance

- Smart shredding sequence which adapts to the operating conditions

[bws_pdfprint_pagebreak]

Typical & Proven Process Applications for the paper industry

- Pulper ragger rope shredding (paper industry)

- Coarse reject shredding (paper industry)

- Fine reject shredding (paper industry)

- Residual non-metallic materials shredding

- Wood scrap shredding

- Special shredding applications (on customer request)

See the following Products as well

- Bale dewiring machine

- COMPAX CFX 60R and CFX 50R

- COMPAX CFX- F 50,60 for Fibrous Residual Material

- ECOMPAX ECX the Simplified Version

- MBX- Belt Conveyors and MCS- Container Stations a.m.mm

- RSP Suldge and Fiber Residual Screw Press RSP 1150,800, and 650

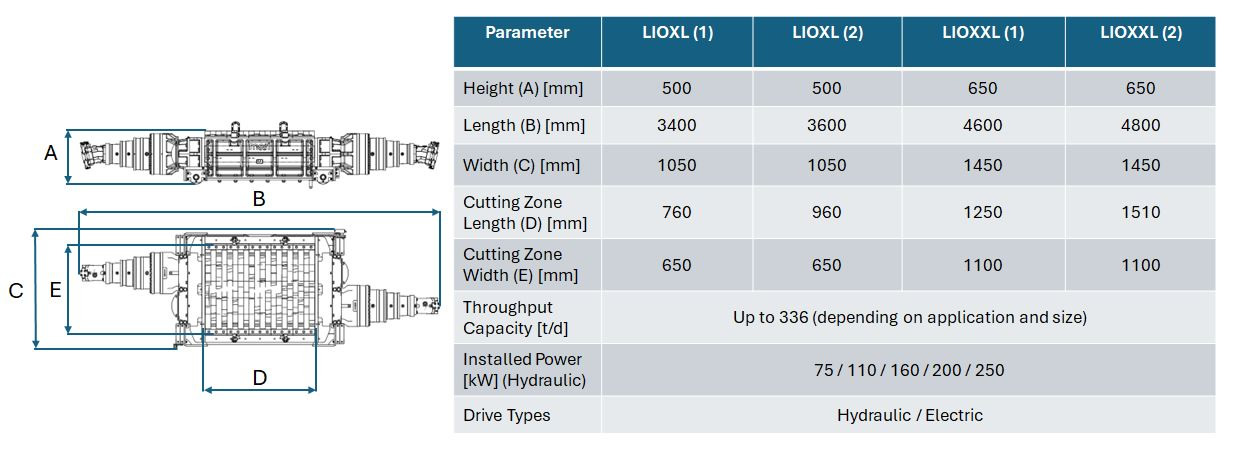

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]