MERI CONTAINER STATION R

[bws_pdfprint_pagebreak]

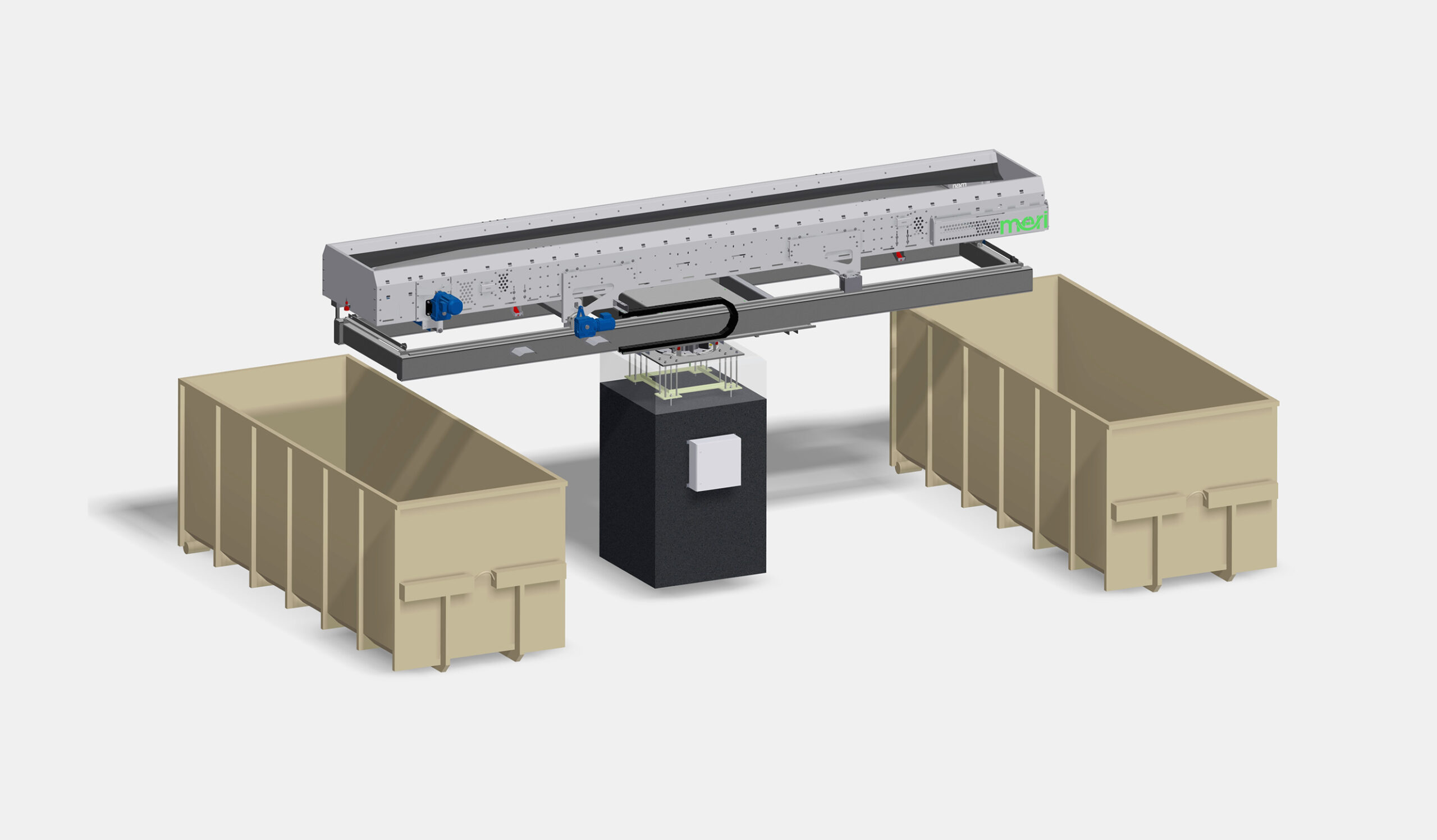

MERI CONTAINER STATION R

Technology

The Meri Container Station R is suitable to fill and distribute un- or pre-treated Rejects & Sludges into commercial or custom-made Containers or bunkers. In consideration of the space conditions, the daily reject amount and other requirements, it is possible to fill fully automatically 2 – 4 containers. The Meri Container- Station R uses MBX meri belt conveyor modules for material transport. The Meri Container- Station R is a well-established reliable equipment, proven in many applications. Up to 5 discharge points per container are possible in strictly order one after the other as well a “special”- filling shop with manual pre- selected independent filling points. The fully automatic sliding- and rotating movements, which are initialized by hight- detection monitoring are allowing also to recognise a missing container and to aim for the next one.

Features

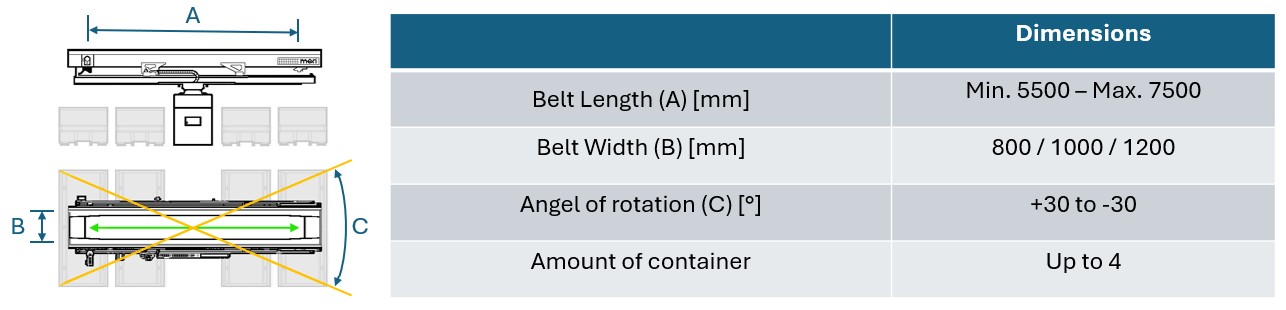

- Stepless position change in lateral direction by 4 flanged rail wheels and 1 gear motor fixed underneath the frame of a MBX conveyor

- Turn movement by central bearing to carry the lateral sliding frame and belt conveyor with gear wheel, which is turned by a drive pinion including gear motor.

- Height detection to monitor filling level and recognise missing containers

- Automatic farther movement to next available filling point under position replication by lateral, & circular position measurement

- Variable speed with std. SEW gearmotors for conveyor, lateral- and circular- movement for optimum power consumption reliable in 24/7 continuous operation

Why to buy

- Long term experienced distribution technology in many container stations worldwide

- Precise distribution onto up to 5 points per container to use storage capacity most efficiently.

- Reliable container filling under keeping of clean- environment

- Distribution of large amounts by generous free belt width & vat moulded section design. (see also MBX- belt conveyor).

- Fully automatic system including filling monitoring & detection of missing containers.

- Several filling sequences (Standard- & manual- pre- selected special job) possible

- Easy maintenance and erection due to quick exchangeable doctor blades, sliding bars, lower return idlers, clamped side rubbers, perforated side covers and modular design

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Distribution of Light weight Reject from Pulping, wet or dry.

- Fibrous rejects/sludges, wet or dry.

- Transportation of bulk reject, pulper rope in certain length or pre- shredded.

See as well the following Products

- Container- Stations MCS- lateral

- MBX- belt- conveyor

- MSC – Spiral conveyors

- Pre- Dewatered trash/reject from TSX-SCREENEX

- LION shredders

- COMPAX CFX- R & F

- MINIPRESS MPX

- Pre- thickened residuals from Elephant- Filter, Sediphant & Screenex

- RSP- screw press sludge

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]