SPIRAL CONVEYOR and DISTRIBUTION SPIRAL for Reject and Residuals Streams

[bws_pdfprint_pagebreak]

SPIRAL CONVEYOR and DISTRIBUTION SPIRAL for Reject and Residuals Streams

Technology

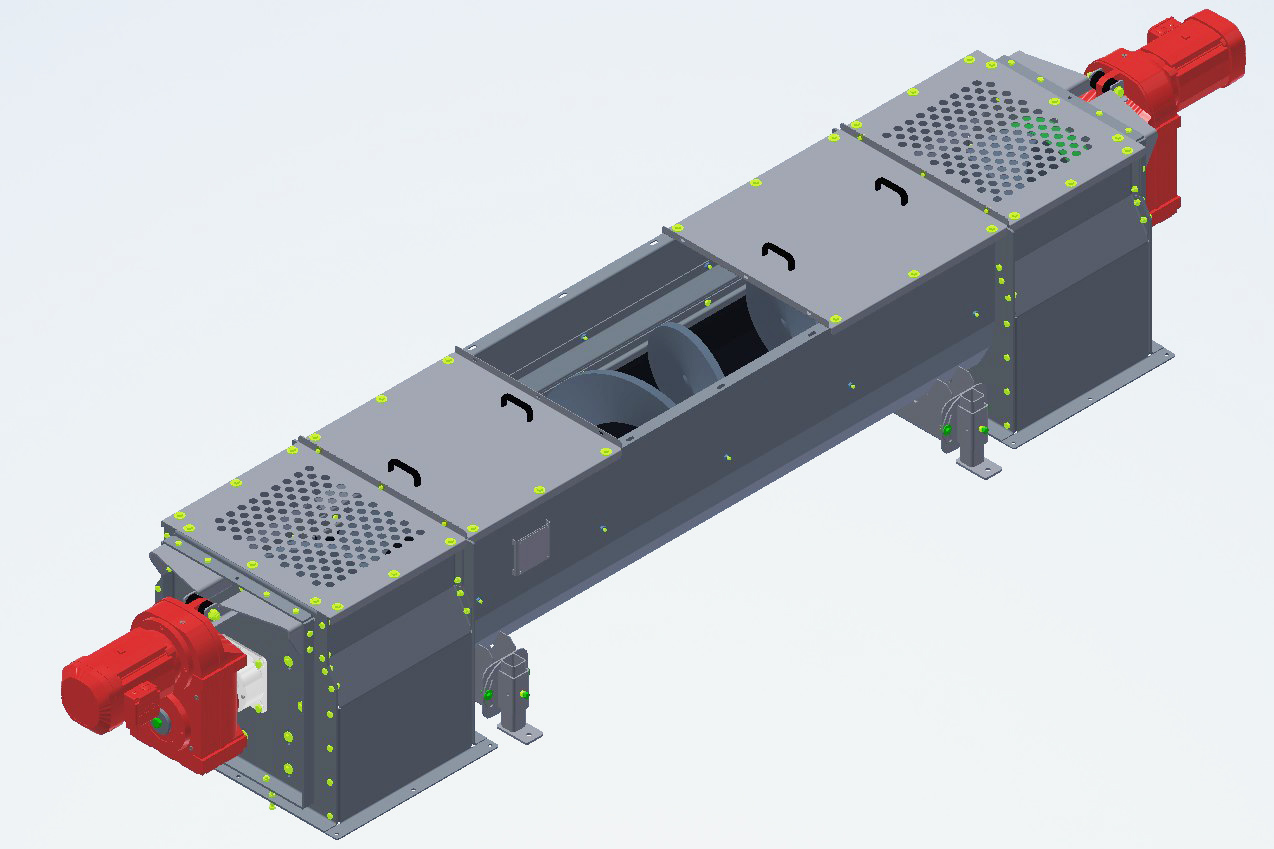

The MERI Spiral Screw Conveyor (MSC) uses a rotating helical screw blade inside a trough, as the screw rotates, pre-treated Reject and Residual material is pushed forward (or backward, depending on rotation direction) working on the principle of friction + gravity, keeping material moving in a controlled flow.

The MERI Spiral Screw Conveyor provides a closed transport and is suitable for dry or wet materials (Reject and Sludge), can operate in steep inclination (30 Deg. and more).

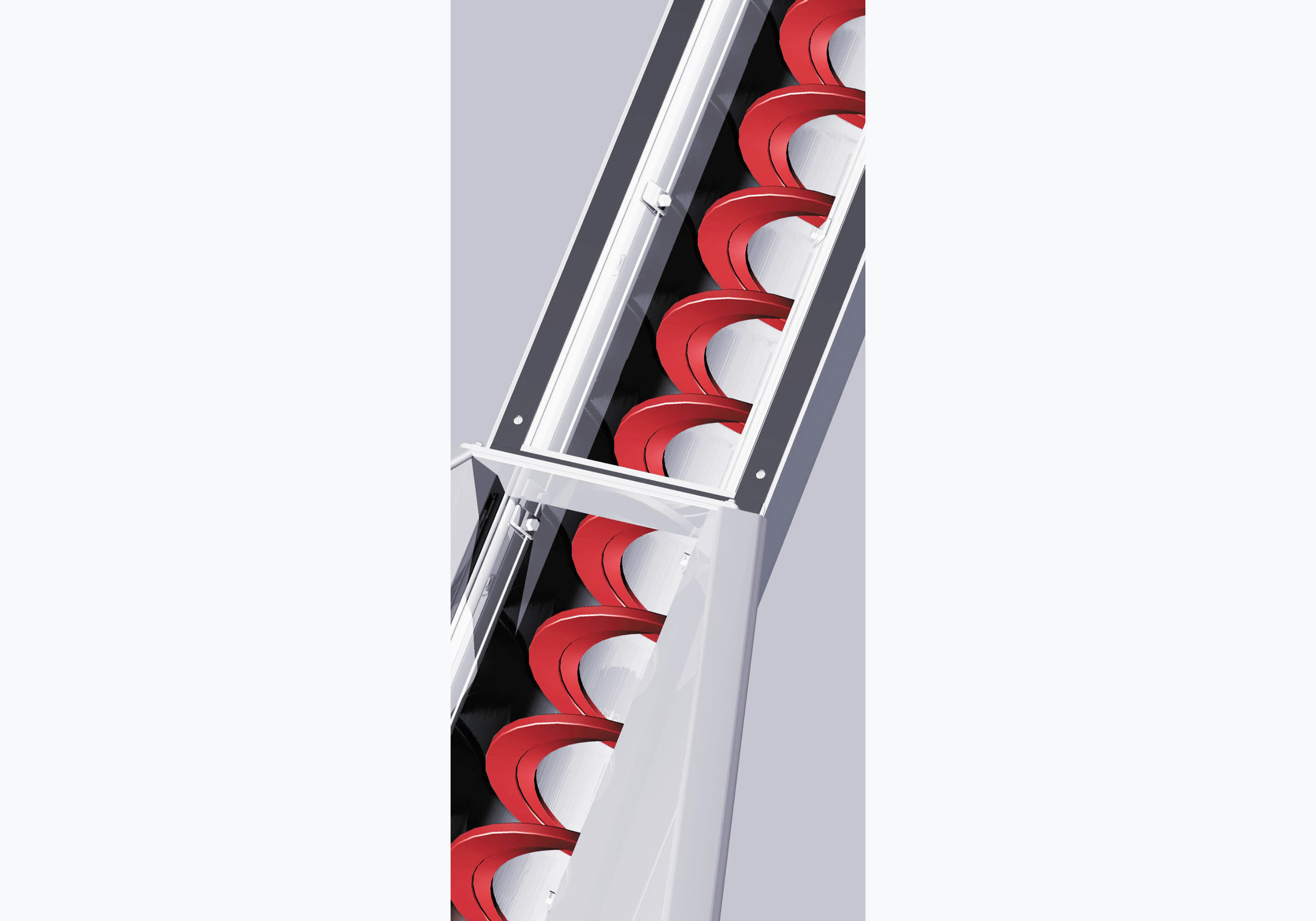

A special version of the MSC is the Distribution Spiral (MDS) which consists of 2 Open Half- Spirals (right and left) and 2 opposite Discharge Points.

The Distribution Spiral (MDS) is loaded from top in the Center and depending on “Rotational Speed and Direction” of each screw the material flow can divided (un-) evenly to the 2 Discharge Points or agglomerated to only 1 Discharge Point.

Features

The MERI Spiral Screw Conveyor (MSC) and the Distribution Spiral (MDS) offer several advanced technical features:

- Closed dust free Transport of pretreated materials.

- Heavy-duty steel flights for abrasive Rejects and Residuals combined with Wear- and guide bars or inlays provide optimal functionality and reliablity

- Enclosed trough which is dust-tight, or for wet materials secures odor containment.

- Variable speed drive for adjustable throughput.

- Horizontal, inclined, or vertical (special applications only) configuration

- Can Single or multiple inlet/outlet points

- Distribution Spiral (MDS) which consists of 2 Open Half- Spirals (right and left) and 2 opposite Discharge Points and provides depending on “Rotational Speed and Direction” of each screw material Division or Agglomeration

- MSC and MDS handle wet, sticky, abrasive, or fine materials better than belts.

Why to buy

- Compact and enclosed > ideal for dusty or odorous waste.

- Durable > built for lightweight (plastic) and abrasive materials including fines (glass, sand, ash).

- Continuous, even feed > perfect for downstream equipment (shredders, boilers).

- Low spillage > less housekeeping compared to belts.

- Can be steeply inclined or vertical > space saving.

- Distribution Spiral (MDS) which consists of 2 Open Half- Spirals (right and left) and 2 opposite Discharge Points and provides depending on “Rotational Speed and Direction” of each screw material Division or Agglomeration > good for distribution or bypass arrangements with downstream dual/twin equipment

Typical & Proven Process

- Transport of pre-treated Reject and Residual Streams (fibrous sludge) within a mill / plant from different loading points to different discharge

- Dust free transport in closed conveyor

- In Reject and Residual (sludge) treatment distribution or bypass arrangements with downstream dual/twin equipment (e.g. 2 Sludge Presses)

See the following Products as well

- Lion Shredder

- Finger Sorter

- Meri Belt Conveyor

- COMPAX screw compactor Series

- ECOMPAX and Minipress

- Sicon Pocket Conveyor SPCS

- RSP Sludge and Residual Press

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]