MMH-DVIR – Dewiring Machine for Virgin Pulp Bales

The most efficient and reliable dewiring and coiling solution for virgin pulp bales available on the market.

[bws_pdfprint_pagebreak]

MMH-DVIR- Dewiring Machine for Virgin Pulp Bales

Technology

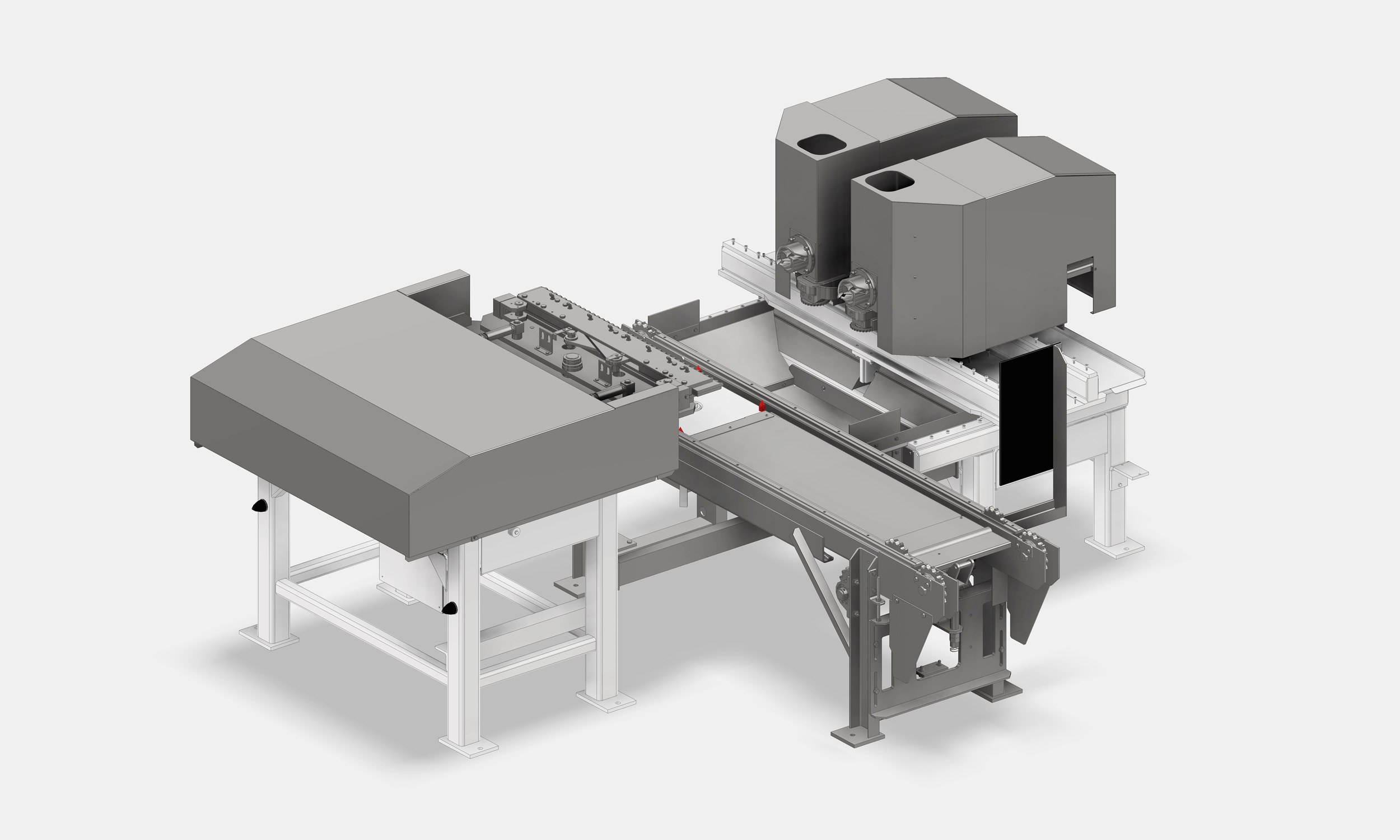

The Meri Dewiring Machine for virgin pulp bales represents a state-of-the-art solution, designed to be both advanced and highly efficient, for the removal of binding wires from virgin pulp bales. This cutting-edge machine integrates the latest handling technologies into a single, versatile system, ensuring optimal performance and reliability. The hydraulic system powers high-force tasks, the pneumatic system manages low-pressure operations, and servo technology ensures swift, accurate movements with precise positioning and exceptional repeatability. Frequency-controlled drives further enhance operational efficiency. There is a control desk near the machine, which includes PLC, available for local Auto/Manual operation.

The machine features a reciprocating knife beam for efficient wire cutting, while the two servo-controlled wire coilers guarantee smooth, fast, and consistent wire handling. A robust hydraulic lift/turn table rotates bales to ensure complete wire removal from all sides. The integrated Meri Material Handling Chain Conveyor transports the bale with ease and maximizes productivity.

Designed for continuous operation, the machine is capable of running 24/7 for up to 10,000 hours straight, depending on the virgin pulp bale characteristics. Its optimized wire coiling system reduces downtime and operating costs, making it the ultimate solution for fast, reliable, and cost-effective dewiring in the paper industry.

Features

- Safe dewiring of single pulp bales with one-sided or crosswise wrapping wires.

- Fast and efficient coiling of single bale wires into neatly compact coils.

- High throughput per hour with exceptional removal efficiency, reaching up to 98% for LBKP and NBKP single bales.

- High level of automation with reciprocating designed knife beam and servo-controlled coilers.

- Cutting-edge vision system capabilities enable optimization of the dewiring process for enhanced efficiency.

- Control desk near the machine, which includes a PLC, available for local Auto/Manual operation.

Why to buy

- Market leading single bale dewiring machine with state-of-the-art technology

- High availability and durable design, ensuring reliable performance and a lifespan that lasts for years

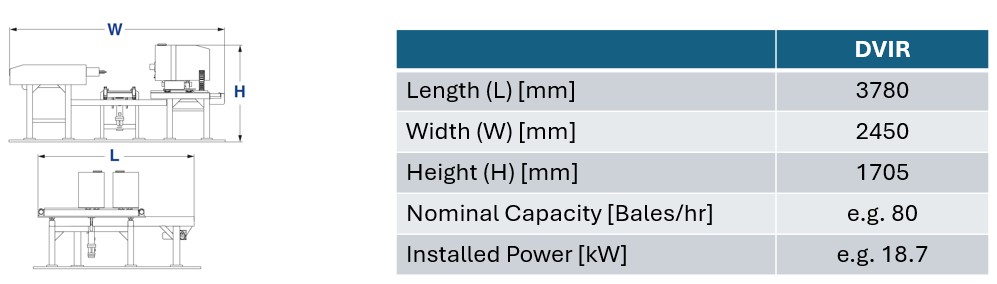

- High capacity (e.g. 80 bales per hour)

- Low operating cost (OPEX)

- Easy servicing and maintenance ensure maximum operational efficiency.

- High wire removal efficiency

[bws_pdfprint_pagebreak]

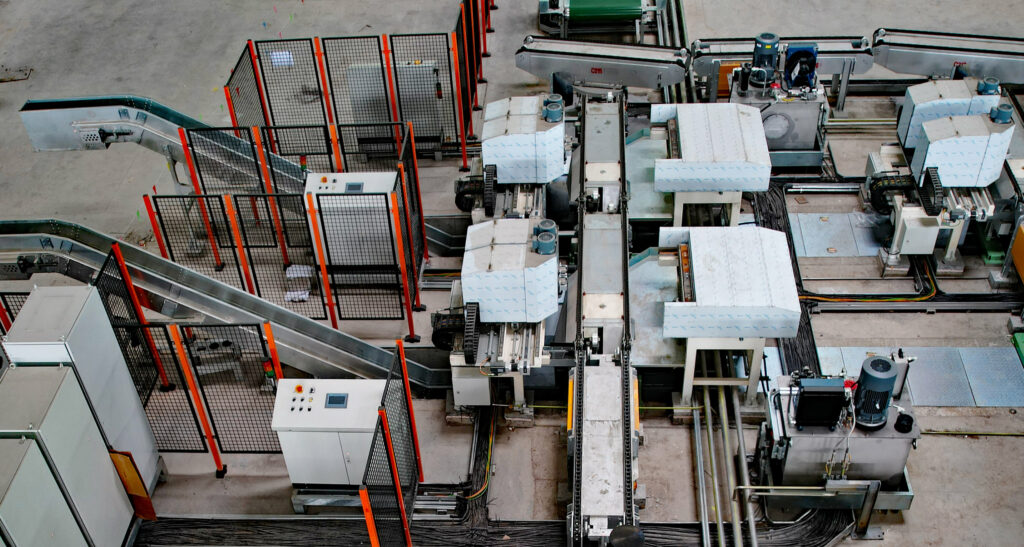

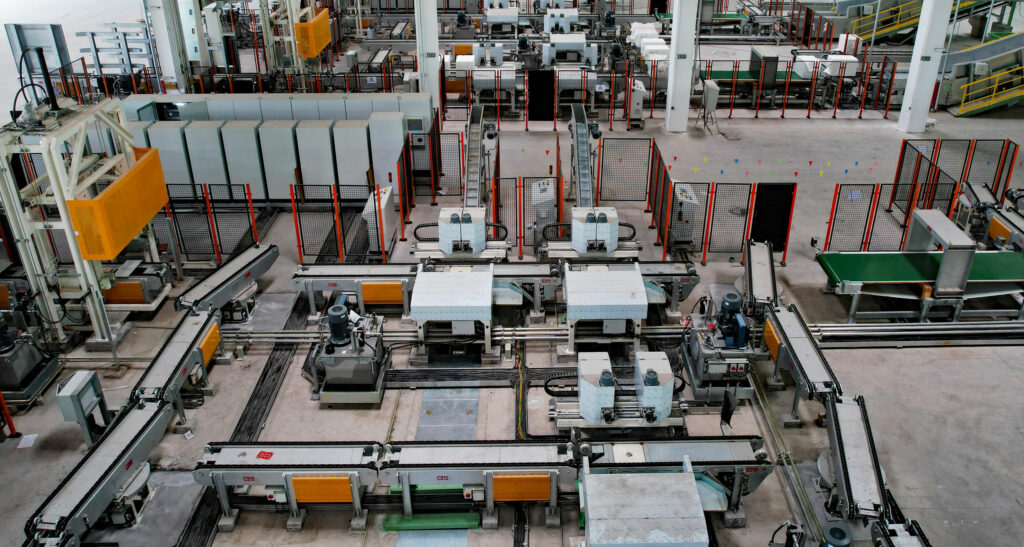

Typical & Proven Process

- Dewiring for single virgin pulp bales

See the following Products as well

- MMH-UDM the Dewiring Machine for Pulp Unit

- MMH-DSU the Destacker for Pulp Unit

- MMH-MD the Metal Detector for Single Bale

- MMH-CC the Chain Conveyor for Unit/Bale

- SC-Slat conveyors for Bale Feeding

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]