MMH MD – Metal Detector

The most efficient and reliable wire detection solution for virgin pulp handling system.

[bws_pdfprint_pagebreak]

MMH MD – Metal Detector

Technology

The Meri Metal Detector is used in conjunction with a belt conveyor after automatic bale dewiring machines for detection of missed magnetic and non-magnetic metals on dewired pulper. This is particularly necessary to produce high-quality papers. It is the preferred wire detecting machine with ease and ultimate performance in virgin pulp handling systems.

Designed for continuous operation, the machine is capable of running 24/7 for up to 10,000 hours straight. Its solid and robust construction reduces downtime and operating costs, making it the ultimate solution for fast, reliable, and cost-effective wire detection in the paper industry.

Features

- Installed behind bale dewiring machine DVIR

- Long lifetime due to solid and robust construction

- The Metal Detector can be integrated into existing systems

- Easy servicing and maintenance ensure maximum operational efficiency

- Reduced personnel costs

- Control cabinet which includes a PLC, available for parameter setting

Why to buy

- Minimized commissioning time on site due to workshop test

- High Sensitivity

- Low operating cost (OPEX)

- High capacity with lowest maintenance

- High availability and durable design

- Reliability

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Virgin pulp handling system

See the following Products as well

- MMH-DVIR the Dewiring Machine for Single Bale

- MMH-UDM the Dewiring Machine for Pulp Unit

- MMH-DSU the Destacker for Pulp Unit

- MMH-CC the Chain Conveyor for Unit/Bale

- SC-Slat conveyors for Bale Feeding

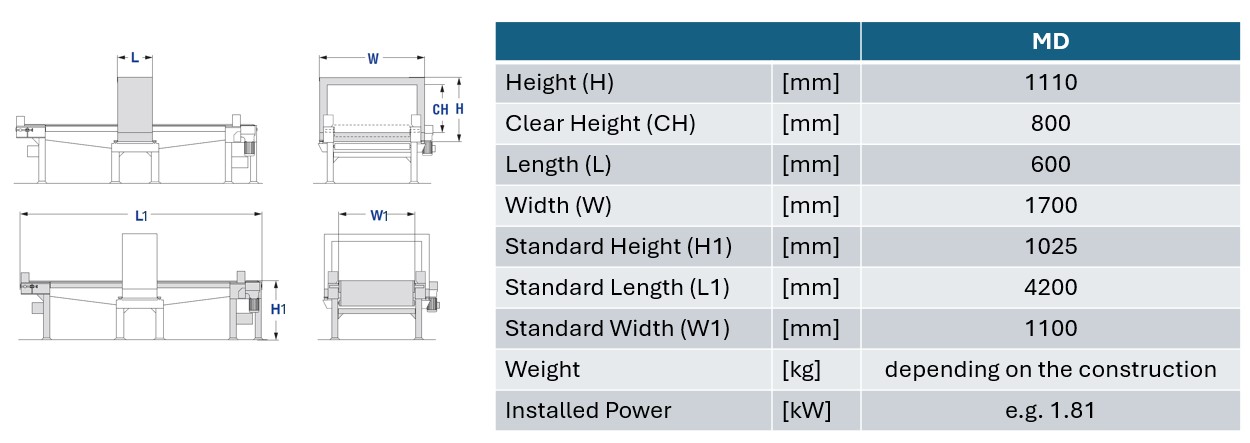

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]