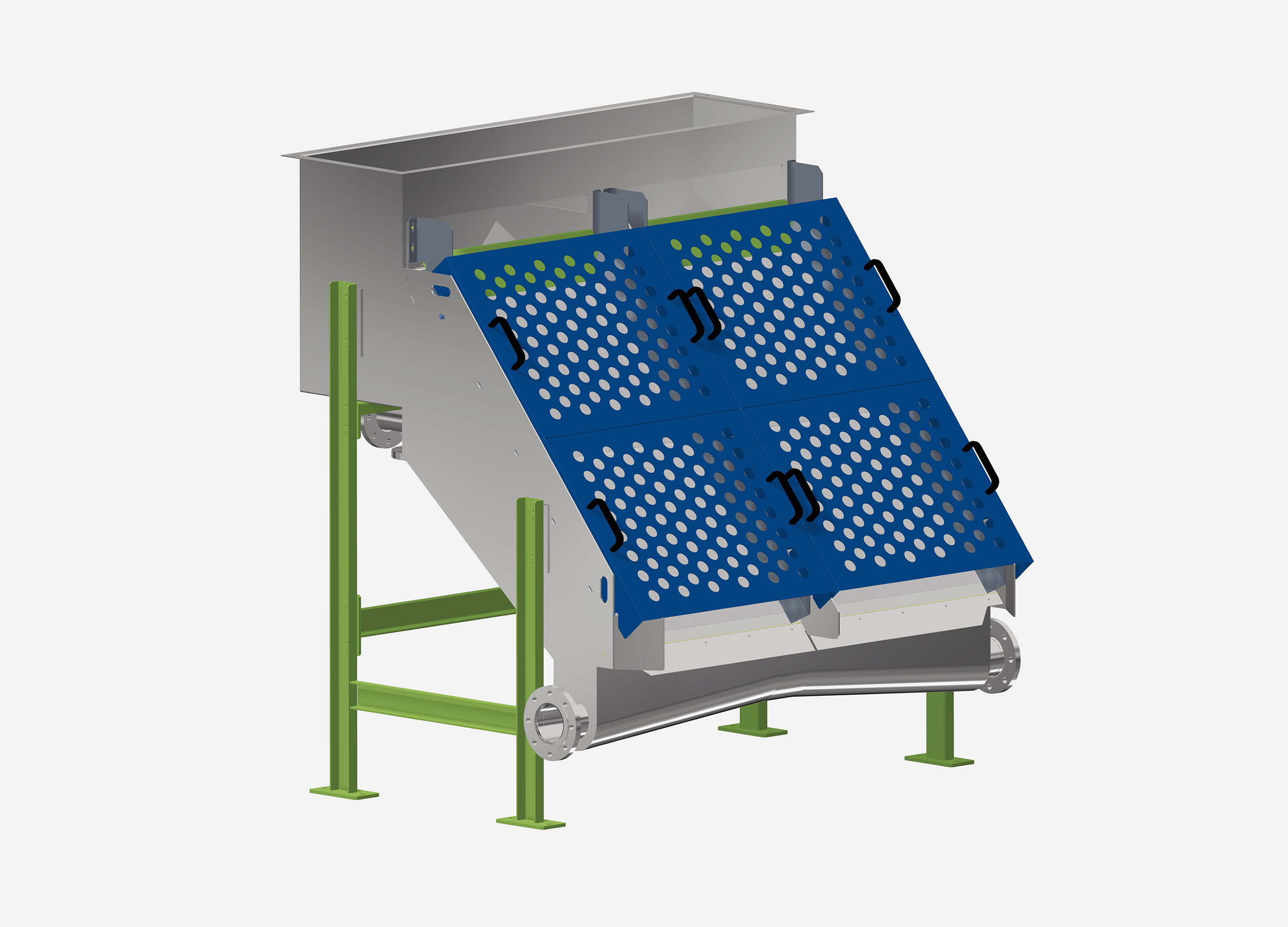

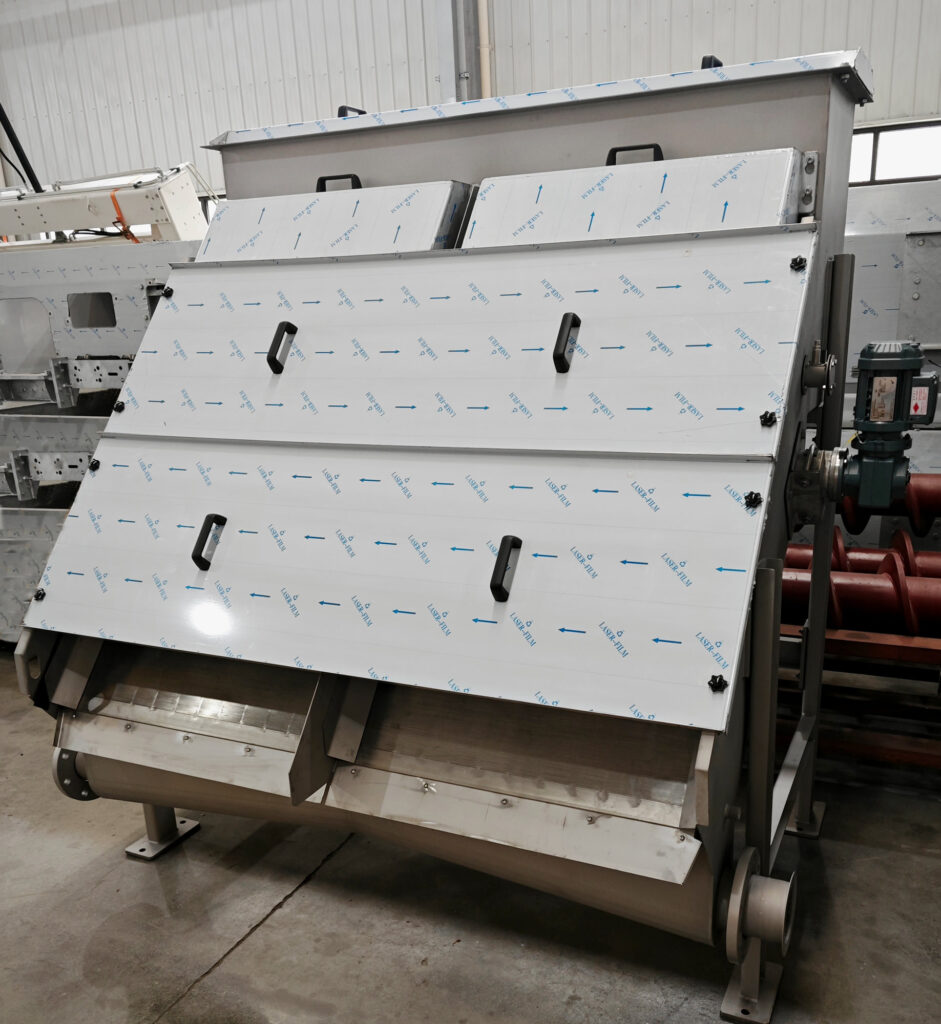

MSFS – Meri Static Fine Screen

MSFS with slot screen element for the Highest Efficiency and most Economical of solid/filtrate separation on the market

[bws_pdfprint_pagebreak]

MSFS – Meri Static Fine Screen

Technology

The MSFS is a simple, highly efficient screen, designed for solid/liquid separation in the Pulp & Paper Industry. It can be used for fiber recovery, thickening, solids removal and fiber/filler separation.

The suspension is pumped to the MSFS feed chamber, and forms a hydraulic attachment to the bars of the screen plate. Thus, the liquid passes through the slots while the separated solids stay on the front face of the screen plate.

The screen plate is supported by a frame which initially ensures quietness and even distribution of the effluent over the entire width of the unit and then accelerates the liquid down the screen plate. The filtered liquid is collected in the screen base.

Feeding chamber separation design, features online inspection and replacement of dewatering screen elements. Specified slot width obtains homogeneous dewatering performance over whole screen elements.

Features

- Cost effective solids/filtrate separation for various pulp and paper applications

- Simple, reliable operation

- Automatic screen plate washing

- Compact, closed design

- Wide screen plate selection

- High availabitily and long lifetime over decades

- Reduced cost for manpower and easy to service and maintain

Why to buy

- Market Leading machine in solid/filtrate separation

- Low operating cost (OPEX)

- Simple design and robust construction

- Very low installation costs, no maintenance

- High availability

- Excellent sustainability

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Solid/liquid separation in the Pulp & Paper Industry

- Fiber recovery

- Reject/Sludge thickening

- Sewer cleaning tasks

See the following Products as well

- COMPAX CFX-F 80 – Screw Compactor

- MINIPRESS MPX Screw Press

- RSP Screw Press

- BLUEDRAIN BDL – Belt Thickener

- ELEPHANT ET – Disk Thickener / Filter

- SEDIPHANT ST

- SEDIMATOR PLUS SMF-P

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]