POLYMERI – Chemical Dosing

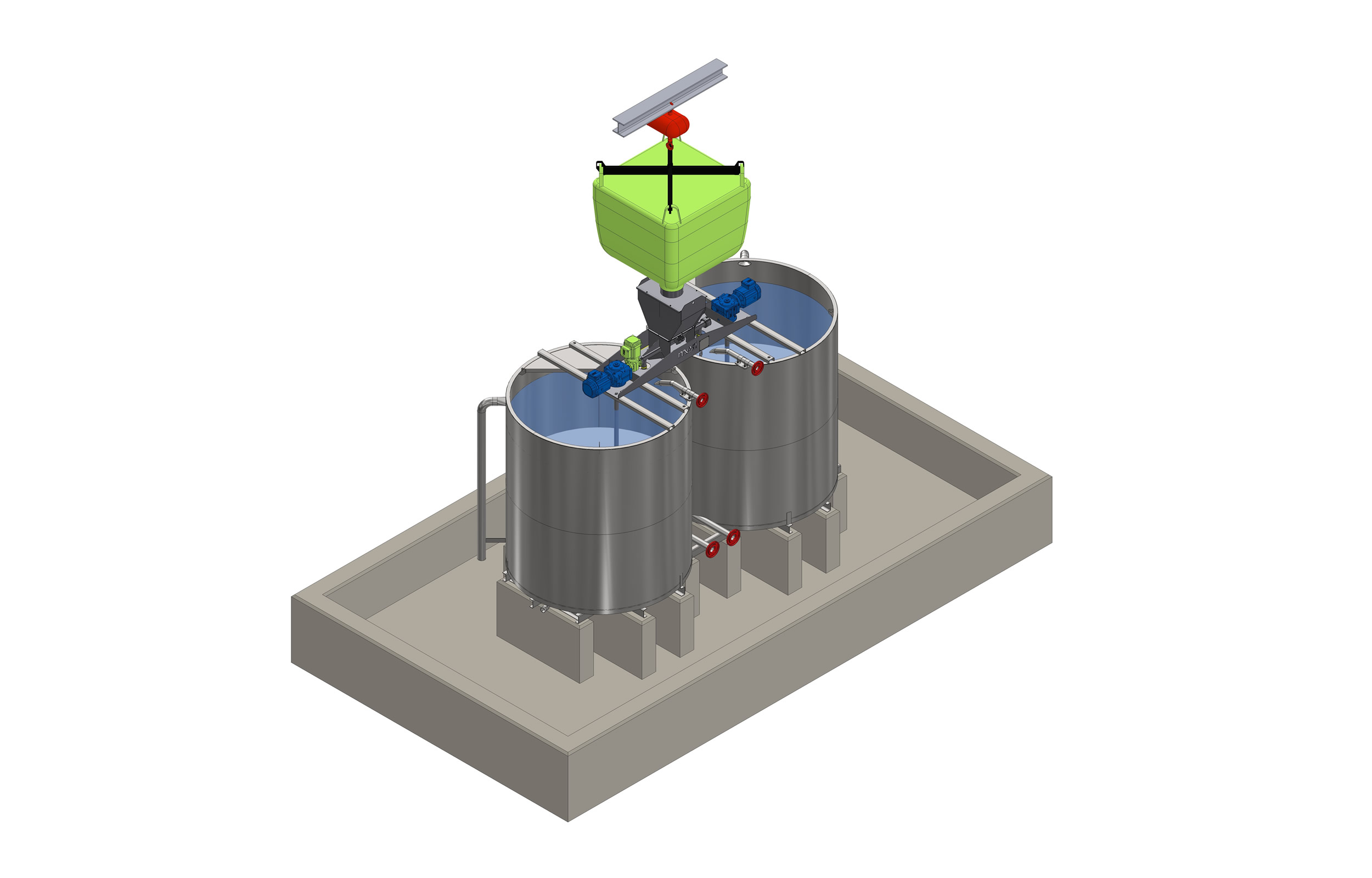

The advanced automatic pulley Mayor preparation system for medium and high quantities

[bws_pdfprint_pagebreak]

POLYMERI – Chemical Dosing

Technology

Polymers are used as advanced chemical aids for many different process steps in paper production such as filtration, effluent treatment and many more. Chemical costs for polymers can be significant so with efficient handling logistics and specific polymeric preparation is significant.

The POLYMERI has preparation and mixing chambers which are operated batch wise alternately.

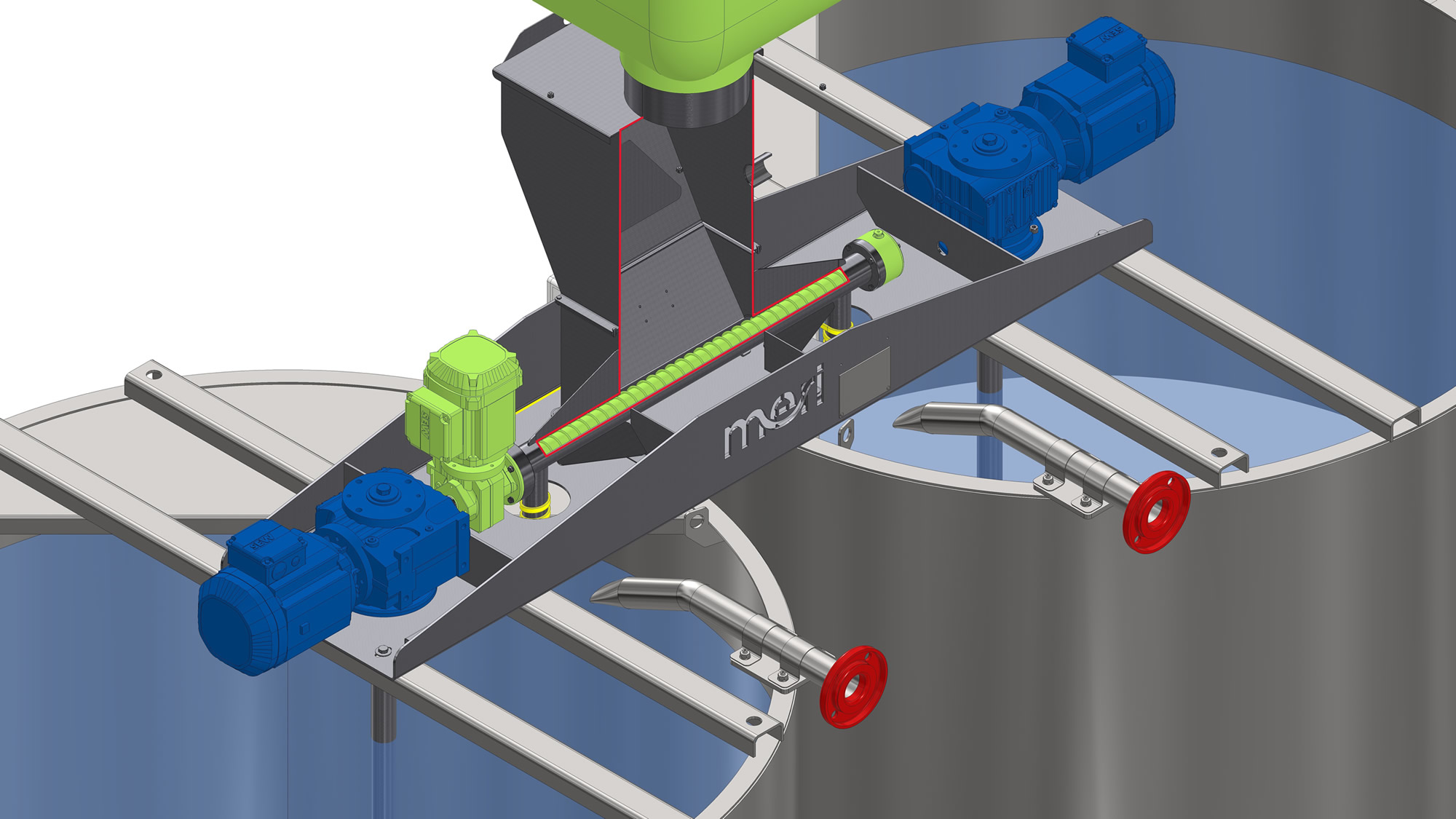

The 1m³ Polymer Powder Big Bag is directly connected to Powder Feed Cone below which lets the powder run into a dosing / metering screw which can rotate in 2 directions, and so with dose powder into batch tank 1 or batch tank 2.

The powder is dosed directly in the inlet water flush during tank filling up to a determined level, corresponding a certified volume.

The water powder ratio can be adjusted automatically by rotation speed and rotation time of the dosing / metering screw.

Polymer dilution and preparation is secured by speed variable dosing / agitators in the tanks

While one tank operates as Polymer Powder dosing, dilution, mixing and aging tank, the other tank is used as storage / pump feed tank for the ready prepared liquid phase polymer.

The 2 tanks are operating fully automatic controlled alternately.

Features

- Fully automatic 2 Chamber Batch Polymer Preparation System for continuous operation and medium – super high capacity

- More than 200 Polymeri Large Scale Installations WW

- Preparation of dosing ready Liquid Polymer from Powder Polymer (Big Bag)

- Advanced Control System allows exact preparation and dosing rates to minimize OPEX

Why to buy

- Best available Technology for applications with high preparation and dosing rates (kg/hour, day) fully automatic.

- Full Integration in Customer DCS possible

- Highest possible operational reliability and Chemical Saving

- All Stainless-Steel Design for trouble free operation and extended lifetime

[bws_pdfprint_pagebreak]

Typical & Proven Process Applications

- Flocculant, Coagulant Preparation for DAF and Sedimentation Applications

- Flocculant Preparation for large scale sludge presses

- Retention aid, and Flocculant Preparation for Stock Prep and PM Applications

See the following Products as well

- DAF Deltapurge, Tauro and all types Sedimentation Clarifiers (CSED, RSED)

- Elephant Filter and Blue Drain

- RSP and MPX Sludge Presses

- Process Applications in Stock Prep and PM

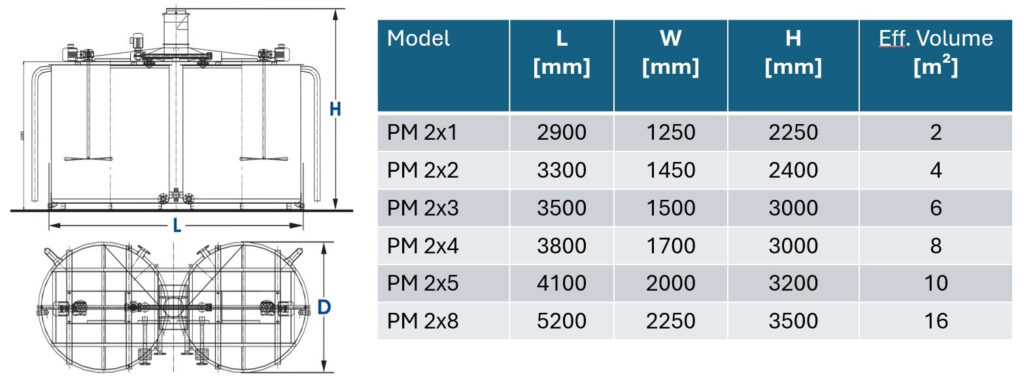

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]