R2S ANAEROBIC REACTOR

[bws_pdfprint_pagebreak]

R2S ANAEROBIC REACTOR

Technology

The R2S Anaerobic Reactor is a two staged EGSB reactor optimized for high-COD load and calcium-rich wastewater. The R2S transforms organic waste loads in the wastewater anaerobically and produces biogas. Active biosludge pellets, consisting of anaerobic bacteria, have a lot of surface contact and effective interaction with the wastewater due to the high upflow velocity and external and internal recirculation. The optimal surface exchange provides optimal access to degradable waste and nutrients for the bacteria to remove COD Load. Its design enables efficient biogas separation through settlers and gas separation tanks, while ensuring robust pellet retention. Further design details include a conical bottom for sludge removal during operation and adjustable feed distribution. The reactors fully gas tight design prevents odor emissions, corrosion and minimizes sulfur deposits, ensuring long-term reliability and low-maintenance operation.

Features

- High-efficiency process performance & control through external and internal recirculation for stable hydraulic flow and optimized surface exchange distribution

- Enhanced sludge fluidization preventing dead zones and supporting even distribution of flow within the pellet sludge bed

- Integrated gas separation tanks ensuring effective biogas extraction and optimal pellet retention

- Fully gas tight tank design preventing odors, corrosion, and sulfur deposits for a safer environment

- Reliable control system with adjustable feeding pipes a internal & external recirculation for stable performance

- Conical bottom for heavy sludge removal and efficient sediment discharge during operation

Why to buy

- Highest COD reduction and energy recovery as biogas, lowering energy costs and waste treatment fees

- Reduced OPEX with minimal chemical usage and efficient anaerobic sludge management and pellets growth, optimized for low to no caustic consumption

- Requires low maintenance due to few moving parts and clog-free operation

- Ensures stable performance, even during feed variation and reliable heavy sludge removal during operation

- Supports sustainability goals by maximizing biogas production and minimizing waste disposal needs

- Offers space-saving design with compact, tall tanks reducing installation footprint and improving operational flexibility

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Anaerobic treatment of high-COD wastewater in paper and beverage industries

- Biogas production from calcium-rich effluents with high COD loads

- Efficient sludge management and sludge growth with reduced calcification and maintenance

- Anaerobic effluent treatment in combination with Lime Trap process provides highest lime (calcium carbonate) removal

See the following Products as well

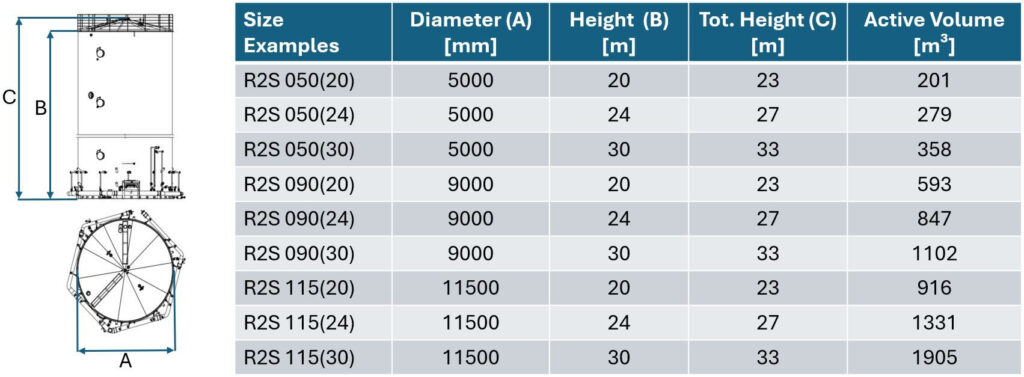

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]