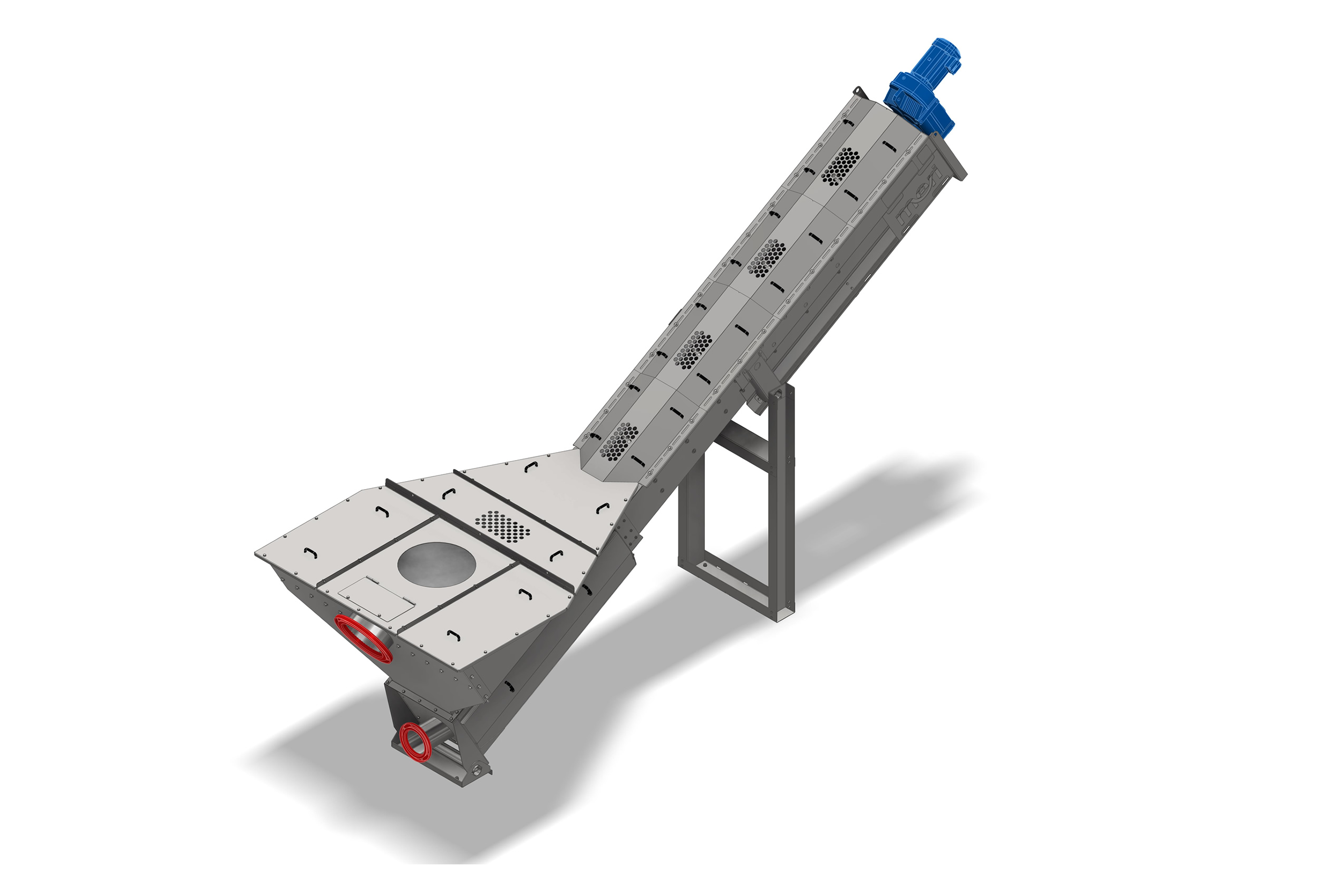

TSX SCREENEX

[bws_pdfprint_pagebreak]

TSX SCREENEX

Technology

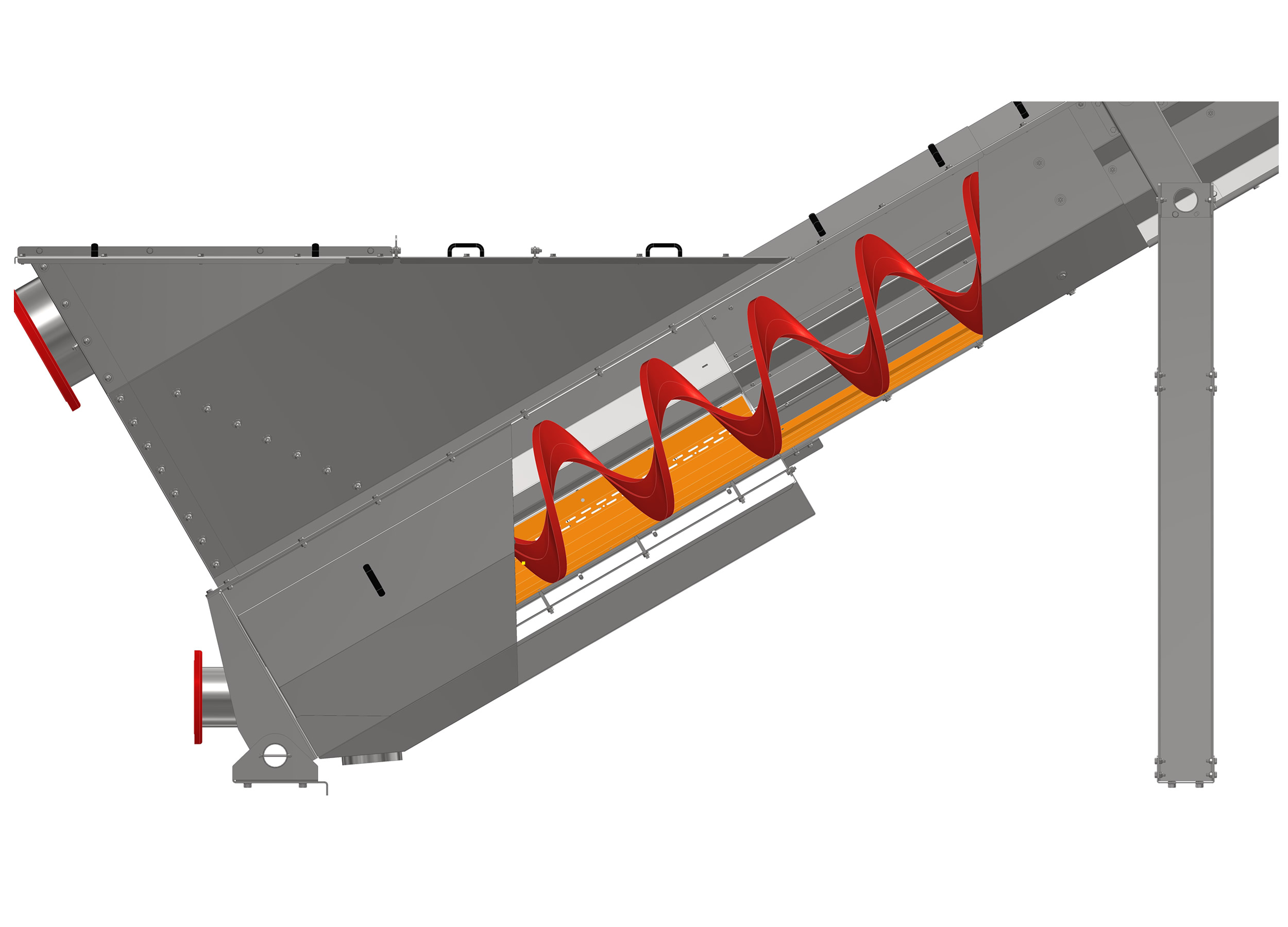

Rejects from junktraps (pulper) which normally occur discontinuously are poured into the inlet chute/pipe of the machine and get dewatered through a multi-element screen in the bottom part of the trough. The size (volume) of the hopper depends on the specific customer requirements so that different sized dump loads can be handled. The sinking level of water guides the rejects into the operating area of the spiral. From there, the rejects are conveyed by the spiral into for example a container. The machine can be operated continuously or discontinuously depending on the extent of the rejects.

Customised designs can be realised upon request for challenging layout requirements. For special applications there is also a version with a pushing drive for the spiral.

Features

- Large buffer volume for discontinuous feed

- Good accessibility by „removable filtrate pan“

- Multi-element screen design

- Enhanced filtration through slotted screen zone

- Blind bottom zone in screen for sand, glass and staples

- Wear bars for a longer lifetime of the wear lining in the U-trough

Why to buy

- Highest dewatering capacity for pulper dumps due to optimized hole and slot arrangement

- Due to different zones in the screen basket, smaller rejects (stones, glass, staples, etc.) can be discharged via the spiral despite the high dewatering rate.

- Special elastic spiral with large free passage for conveying even large rejects

- Adjustable screen position for enhanced self cleaning effect

- Easy maintenance thanks to hinge-able legs and a good access to the spiral

- Enclosed design for cleanliness and safety

[bws_pdfprint_pagebreak]

Typical & Proven Process Applications for the paper industry

- Heavy weight junk traps of low consistency pulper systems

- Heavy weight rejects from junk traps of detrashers of discontinuous & continuous pulper systems

See the following Products as well

- Bale dewiring machine

- COMPAX CFX 60R and CFX 50R

- COMPAX CFX- F 50,60 for Fibrous Residual Material

- ECOMPAX ECX the Simplified Version

- MBX- Belt Conveyors and MCS- Container Stations a.m.mm

- RSP Suldge and Fiber Residual Screw Press RSP 1150,800, and 650

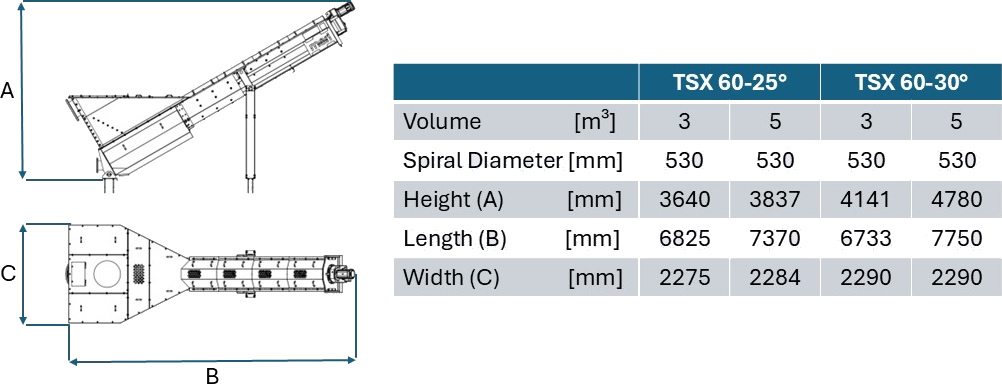

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]