SICON Pocket Conveyor

An unique Transportation System for Reject and Residuals

[bws_pdfprint_pagebreak]

SICON Pocket Conveyor

An unique Transportation System for Reject and Residuals

Technology

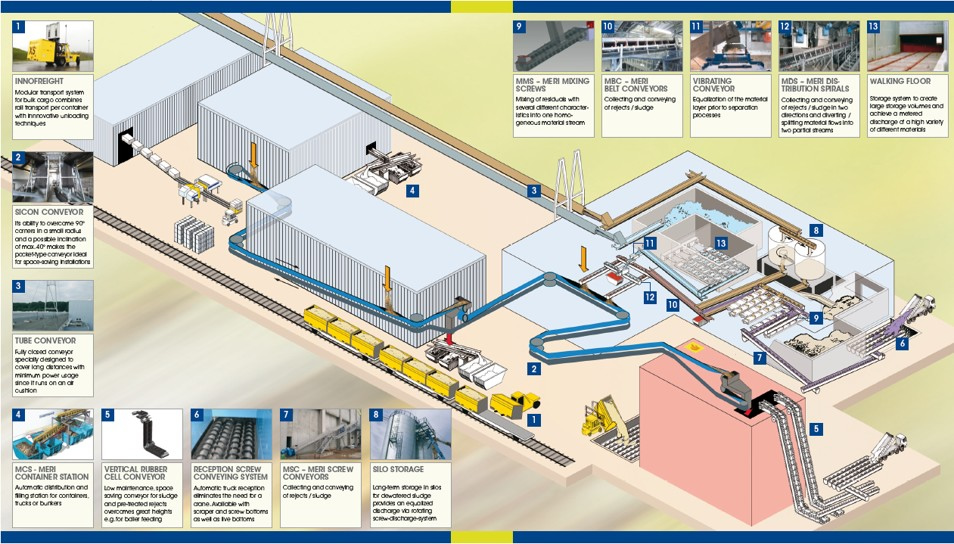

The Sicon Pocket Conveyor System (SPCS) is a unique specialized, closed-belt conveying system designed for flexible, dust-tight, and steep-inclined conveying, on straight and curved conveying tracks.

This special conveyor belt is designed with flexible sidewalls and steel cord reinforcement in a way that the belt edges are joined together to form a “Tubular Pocket Shape” (like a hose) that encloses the pre-treated Reject- and Residual Material, and runs on supporting and guiding roller sets arranged in pairs which are installed along the conveying track.

For Material feeding / loading the “2 -Belt -Halfs” open for Loading form the top, for Material-Discharge the belt opens and runs over “ a “Top-Down- S-Guidance” and releases the material at the designated point.

The Sicon Pocket Conveyor System allows single or multiple loading and discharge points on the same conveying track, which gives maximum process flexibility.

An additional RFID Transponder System allows as well the “The Transponder Identified Designated Transport” of different materials in the same conveyor using different loading and discharge points.

The Sicon Pocket Conveyor System secures “closed dust free transport” along every imaginable conveying track including curves, rectangular turning, steep inclination and meanwhile it is extremely compact and space saving.

Features

The Sicon Pocket Conveyor System (SPCS) offers several advanced technical features:

- Closed dust free Transport of pretreated materials.

- SPCS allows single or multiple loading and discharge points on the same conveying track, which gives maximum process flexibility

- SPCS is routable along every imaginable conveying track, including curves, rectangular turning, steep inclination and provides lowest energy consumption.

- SPCS is extremely compact and space saving transportation system

- The SPCS optional Transponder System allows as well the “Sectinal Transponder Identified Designated Transport” of different materials in the same conveyor using different loading and discharge points.

- SPCS is perfect for upgrade and retrofit of existing plants.

- Low-maintenance idler system, belt supported by idler pairs that require minimal service.

- Environment-friendly, prevents dust and odor emissions

Why to buy

High-value recovery – Extracts aluminum, copper, and other non-ferrous metals that can be sold.

- space-saving > can replace multiple conveyors with one curved route.

- Dust- and spill-free > ideal for waste with high fines, light fractions, or odor issues.

- Handles difficult routes / tracks > curved layouts, steep inclines, and confined plant spaces.

- Protects environment & operators > reduced dust, noise, and spillage.

- Lower maintenance & downtime > fewer transfer points, enclosed belt reduces wear.

- Durable > strong enough for both light (RDF, plastics) and heavy (ash, scrap) materials.

- Versatile > can serve multiple waste streams within the same plant.

Typical & Proven Process

- Transport of pre-treated Reject and Residual Streams within a mill / plant from different loading points to different discharge points e.g. to the power plant

- Dust free transport in closed conveyor along every imaginable conveying track, including curves, rectangular turning, steep inclination.

See the following Products as well

- Lion Shredder

- Finger Sorter

- Meri Belt Conveyor

- COMPAX screw compactor Series

- ECOMPAX and Minipress

- MSC Meri Screw Conveyors

- RSP Sludge and Residual Press

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]