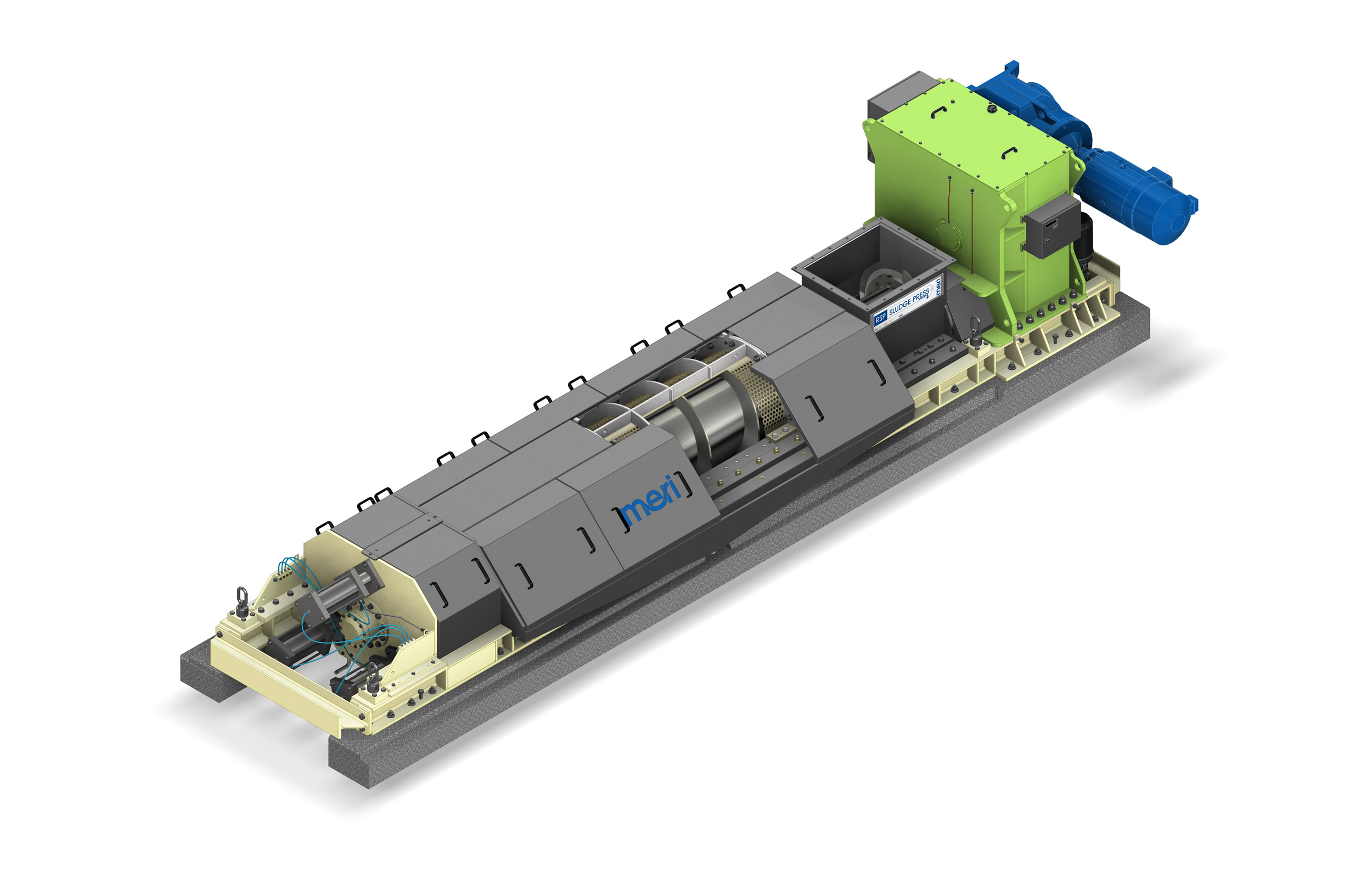

RSP Screw Press

Advanced Sludge Dewatering Solution for Paper Mills

[bws_pdfprint_pagebreak]

RSP Screw Press

Advanced Sludge Dewatering Solution for Paper Mills

Technology

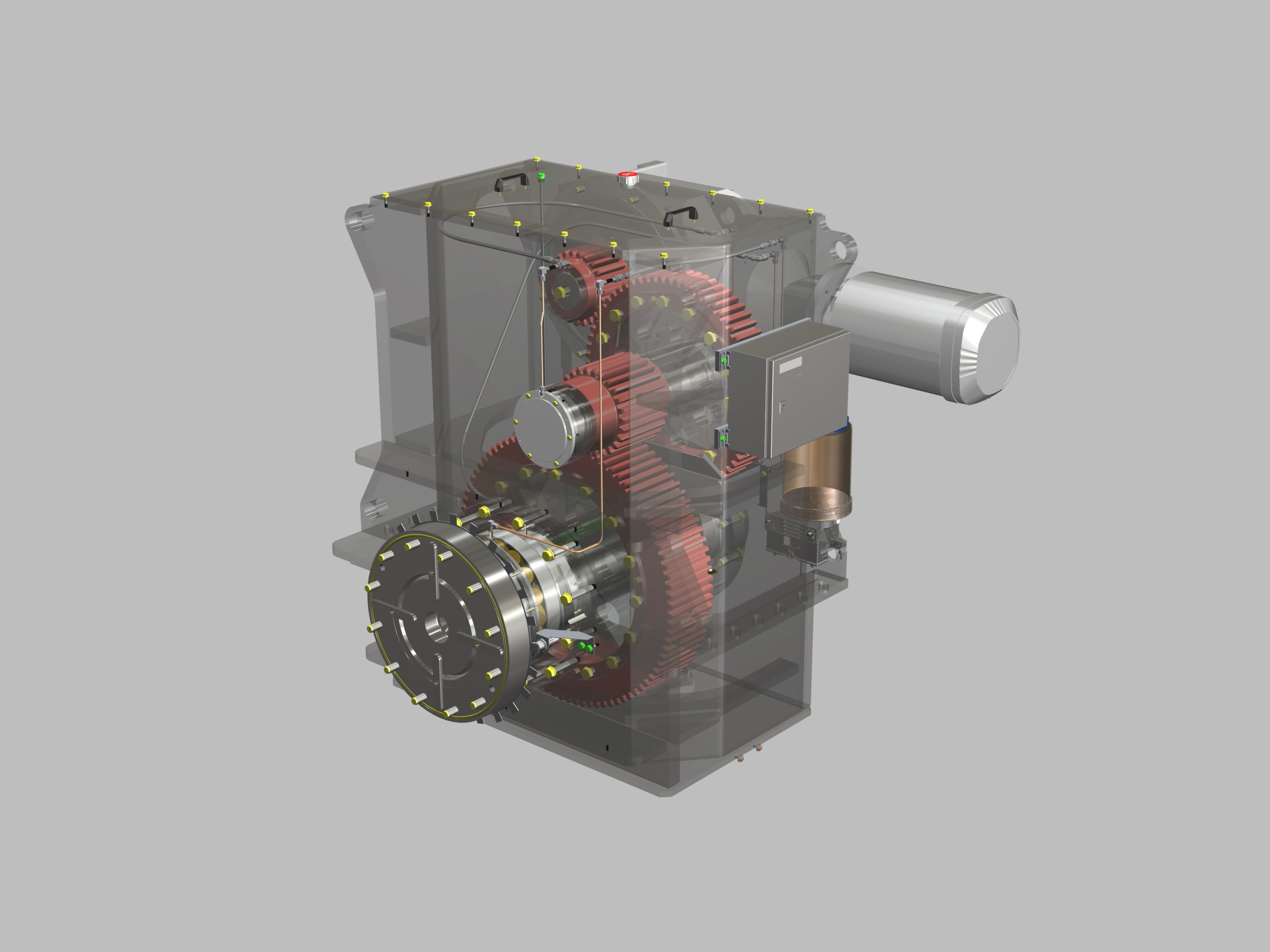

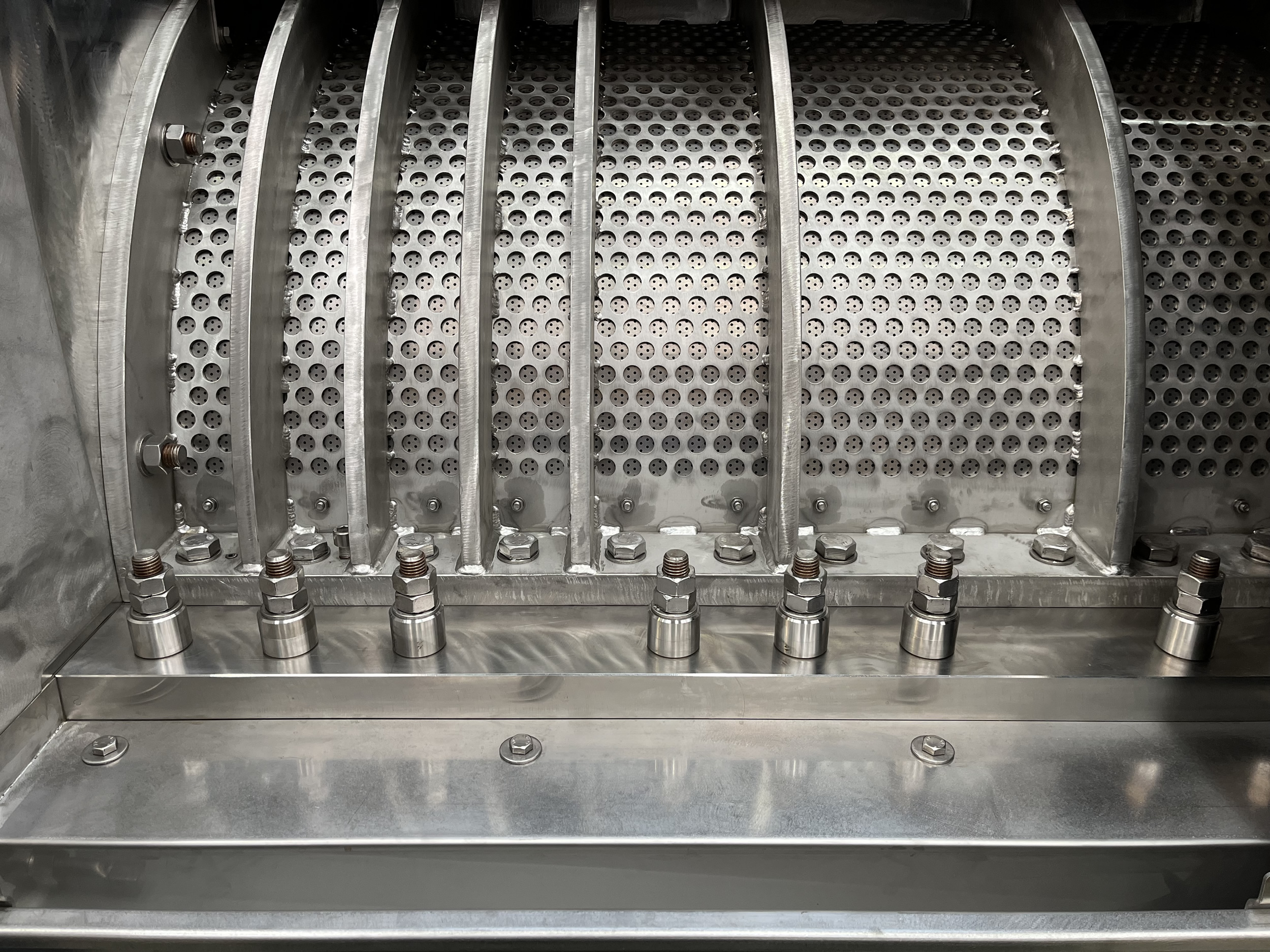

The RSP Screw Press utilizes advanced dewatering technology to efficiently handle sludge from paper production processes. It operates with a screw press mechanism enhanced with a pneumatic counter-pressure system, ensuring high dryness and stable output consistency of the sludge. The sludge is initially dewatered by gravity in the feed section. It is compressed as it progresses through the tapered press screw, which decreases additionally the flight pitch. A unique screen plate at the end of the screw shaft facilitates additional water drainage. Torque control automatically adjusts the screw speed based and counter pressure on sludge consistency, optimizing performance for varied sludge compositions and enhancing energy efficiency.

Features

- High dryness achieved through a specialized screw geometry combined with a counter-pressure system.

- Various screen hole sizes for adaptability across different sludge characteristics.

- Sturdy press design enables high pressure for maximized outlet consistency.

- Heavy-duty frame and “wear-shoes” for extended machine life.

- Modular covers for easy access and maintenance of dewatering screens.

- Cost-effective screen wear plate replacement due to modular, half-screen construction.

Why to buy

- Delivers rapid ROI by achieving high sludge dryness (55–65%), reducing disposal and handling costs.

- Minimal maintenance with bolted, easily replaceable, wear-resistant shoes and screen segments.

- High operational availability with easy controls and automated torque adjustment.

- High throughput capacities available, up to 150 bdt/day per machine.

- Wide application ranges for different sludge types.

[bws_pdfprint_pagebreak]

Typical & Proven Process

- Dewatering of thickened Sludge & Reject mixtures

- from Dewatering of pre-thickened sludge and fibrous residuals:

- from LC-Cleaning and Fine Screening.

- With or without defined content of bio-sludge from effluent treatment.

- From water clarification (DAF units, primary clarifiers, etc.).

- From De-Inking plants.

- From stock De-Ashing / Washing.

See the following Products as well

- Sludge/Reject Pre-Dewatering by ELEPHANT

- BlueDrain Belt Thickener

- COMPAX CFX-F 50,60 & 80

- MINIPRESS MPX 30, 40 & 50

- MSC- Spiral conveyors and related bunker- & container filling- & distribution systems

- POLYMERI Polymer Preparation Unit

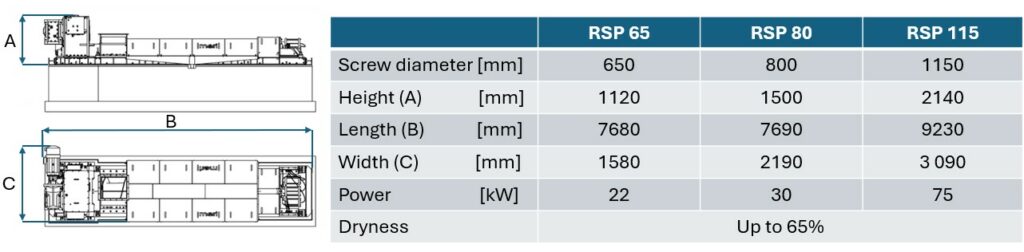

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]