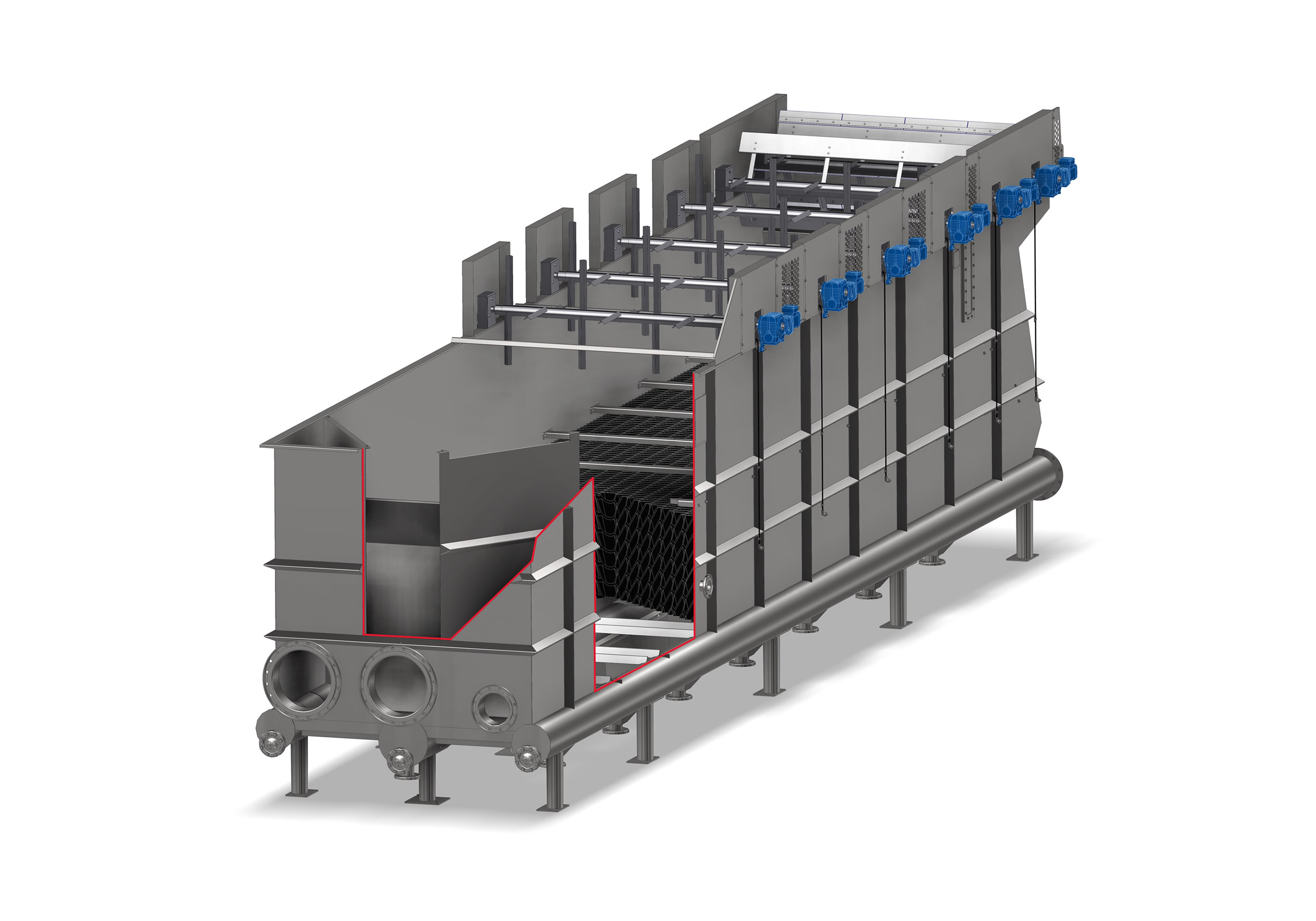

TAL TAURO – Dissolved Air Flotation Clarifier

The TAURO is designed for compact installation with high performance separation

[bws_pdfprint_pagebreak]

TAL TAURO – Dissolved Air Floatation Clarifier

Technology

The TAURO is a rectangular Dissolved Air Flotation system, which features lamella technology for a highly effective flotation area. The TAURO combines high-performance DAF technology with a compact tank design. The rectangular shape and inclined lamella modules provide the clarifier tank with a small footprint. This makes the TAURO unit suitable for tight installation space requirements.

Features

- High performance Dissolved Air Flotation clarifier combining free flotation and lamella separation in one unit.

- Low installation space requirement.

- Increased effective flotation area in respect to the installation area.

- Simple piping to inlet/outlet at the tank.

- Improved sludge dewatering through paddle/dewatering ramp combination.

- Fully modular design to fulfill any layout requirement.

- Basic operation and high process flexibility.

- Universal Dissolving System with a state-of-the-art air dissolving technology.

Why to buy

- High performance Dissolved Air Flotation clarifier combining free flotation and lamella separation in one unit.

- Increased effective flotation area in respect to the installation area.

- Simple piping to inlet/outlet at the tank.

- Improved sludge dewatering through paddle / dewatering ramp combination.

- Unique lamella design for maximized separation surface and minimized chemical consumption.

- Ability to handle high TSS loading, without efficiency reduction.

- Minimized installation costs.

[bws_pdfprint_pagebreak]

Typical & Proven Process Applications

- Save-all applications for fiber recovery in paper machine water loops.

- Filtrate and loop clarification for removal of colloidal dissolved contaminants and micro stickies to improve operation ability and product quality.

- White water treatment and washer filtrate clarification

- Filtrate thickening for removal of fines and ash

- Closing of water loops and reduction of freshwater consumption

- Clarification of primary and secondary mill effluent

- Removal of anionic trash and pitch

- Thickening of biologically activated sludge in effluent treatment plants

- Other industrial applications for food, oil, or chemical industry- please ask for details

See as well the Following Products

- Universal Dissolving system

- Circular Sedimentation Tank

- Elephant

- Dinoscreen

- LimeTrap

- DeltaPurge

- Vulcano

- GyroSand

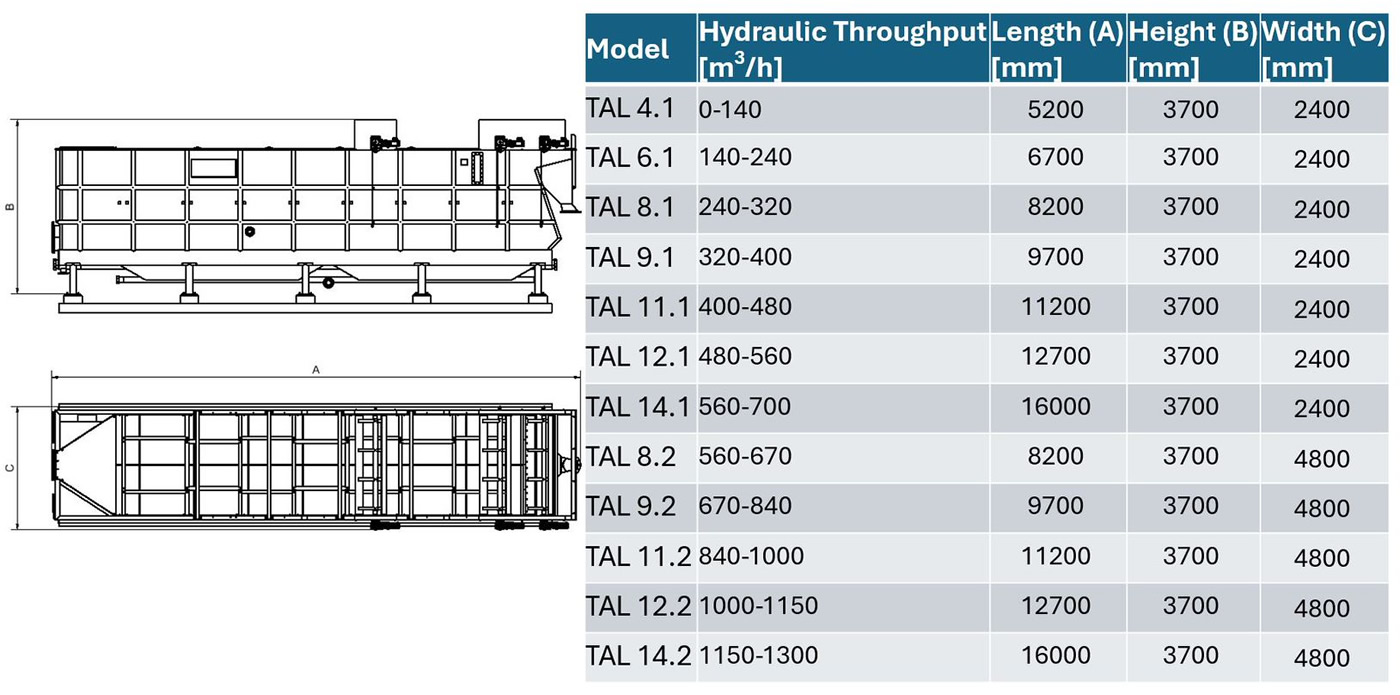

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]