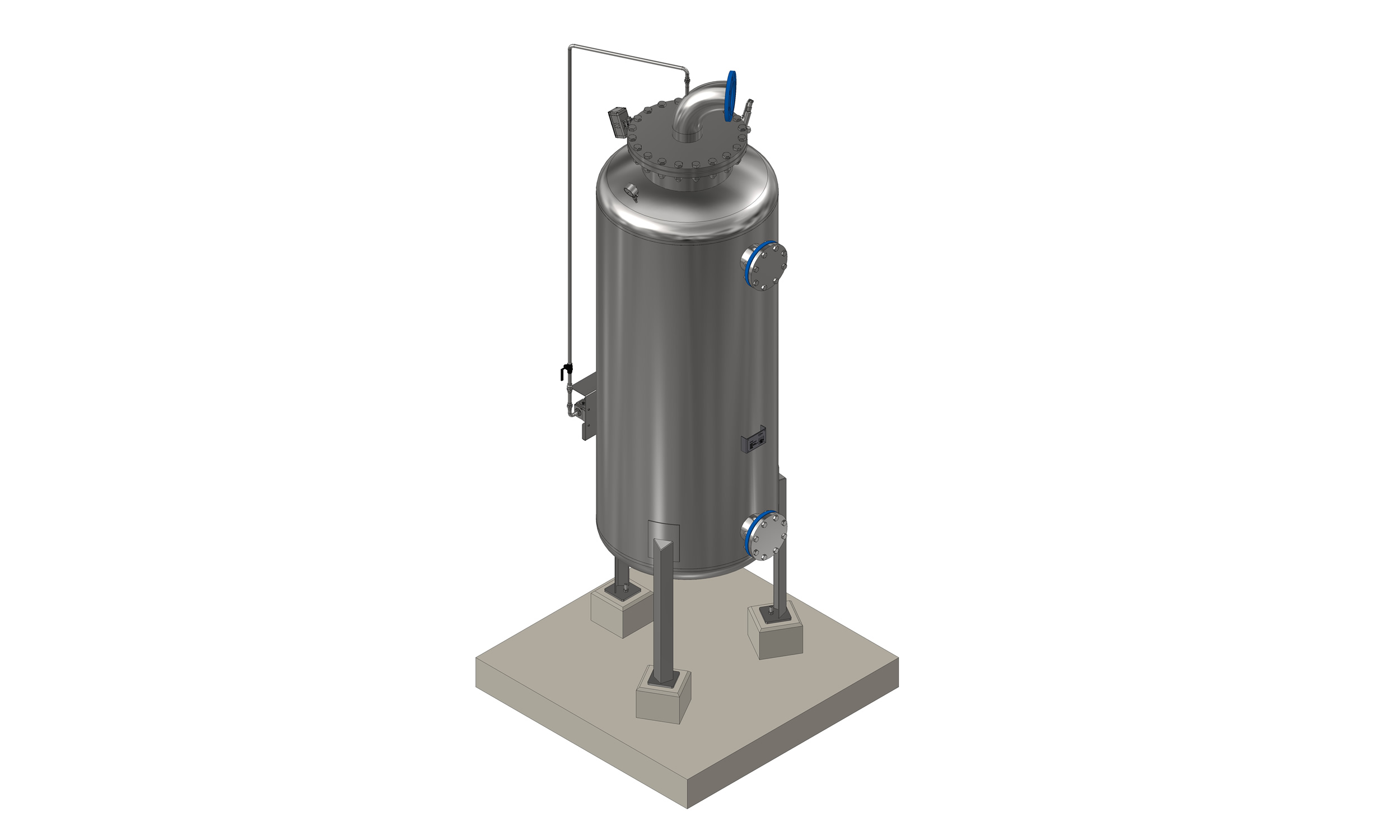

UDS Air Dissolving Reactor (DAF Saturator)

[bws_pdfprint_pagebreak]

UDS Air Dissolving Reactor (DAF Saturator)

Technology

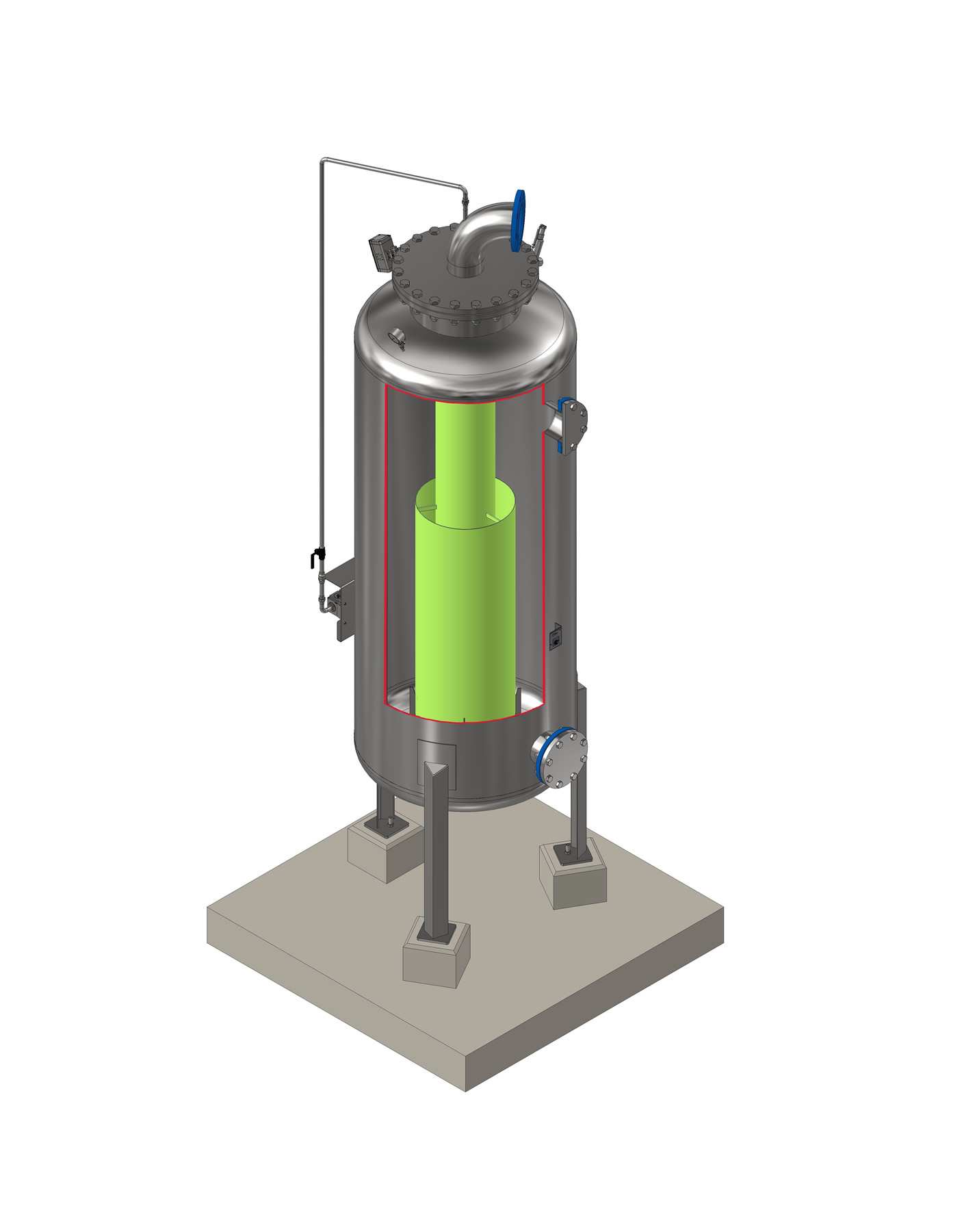

The UDS Air Dissolving Reactor is a pressure vessel, where air is dissolved into a nozzle guided water stream under elevated pressure and variating flow velocity.

With the “Top Down Flow” the air is injected at the highest flow velocity for maximum dissolving efficiency and the “Up – Down Flow design” secures the separation of big bubbles and re-suction into the high speed dissolving tube.

When that pressurized, saturated water is released back to atmospheric pressure in the flotation tank, the dissolved air forms a cloud of microbubbles (10–100 µm).

These microbubbles attach to suspended flocs, fats, or oils, and float them to the surface

Features

- Compact Reactor Design with high velocity dissolving and big bubble separation.

- Technology secures real formation of microbubbles (10–100 µm)

- Reliable Operation even with high solids content in the UDS Reactor feed (Efficient Air Dissolving even in Partial Stream non clarified raw water)

- Maintenance free operation, no clogging, no replacement of air diffuser candles or similar necessary

Why to buy

- UDS Air Dissolving Reactor provides reliable generation of microbubbles (10–100 µm) at any time in any condition even with high solids loaded water in Recycle or Partial stream flow mode

- Maintenance free operation, no clogging, highest efficiency

- Ability to handle high TSS loading, without efficiency reduction.

- Minimized installation costs.

Typical & Proven Process

- Micro Bubble generation for the application of Dissolved Air Flotation

See the following Products as well

- DeltaPurge

- Tauro TAL

- Tauro TAM

- Elephant

- LimeTrap

- GyroSand

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]