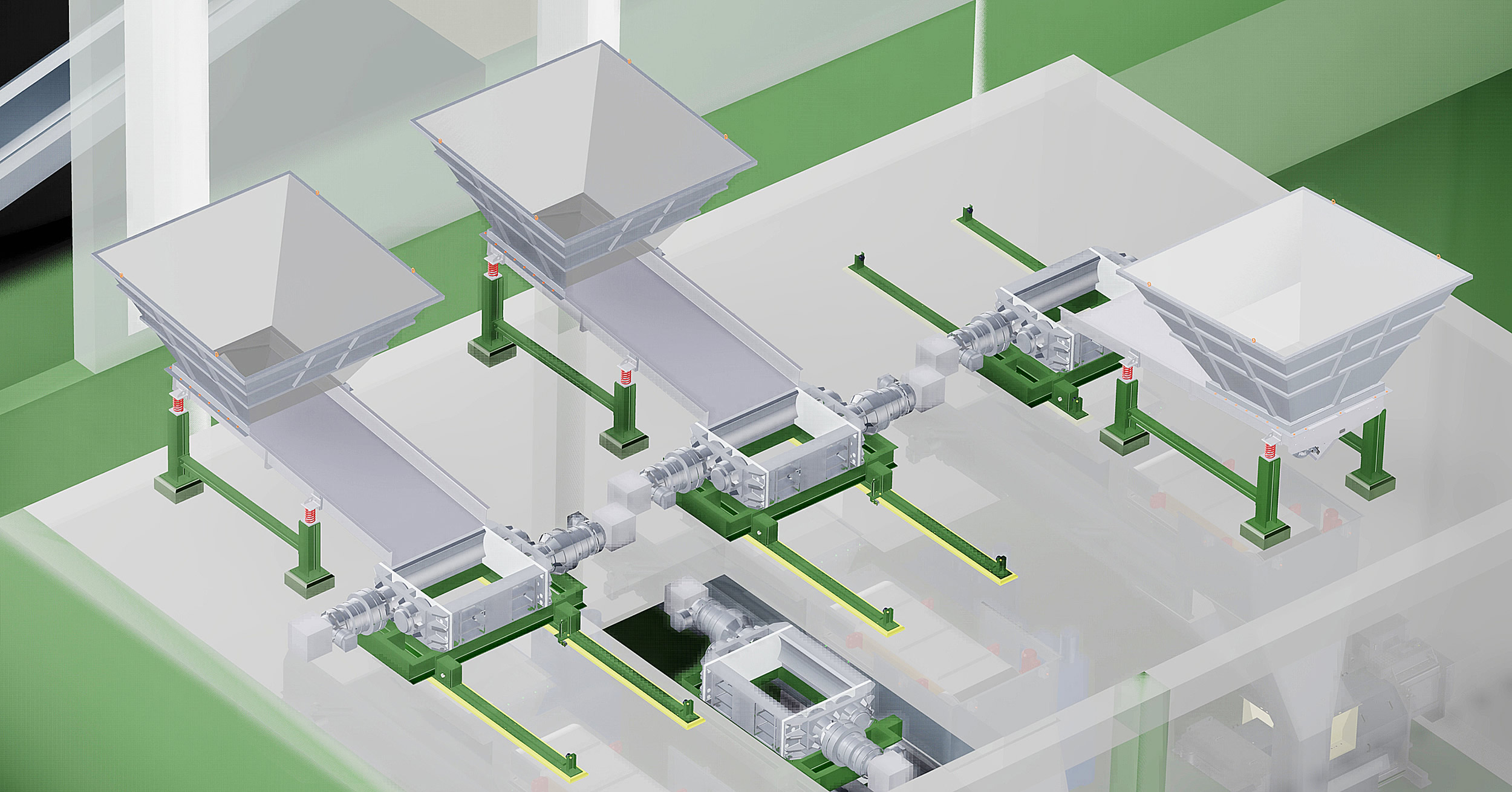

MERI VIBRATING CONVEYOR for Reject and Residuals Streams

[bws_pdfprint_pagebreak]

MERI VIBRATING CONVEYOR for Reject and Residuals Streams

Technology

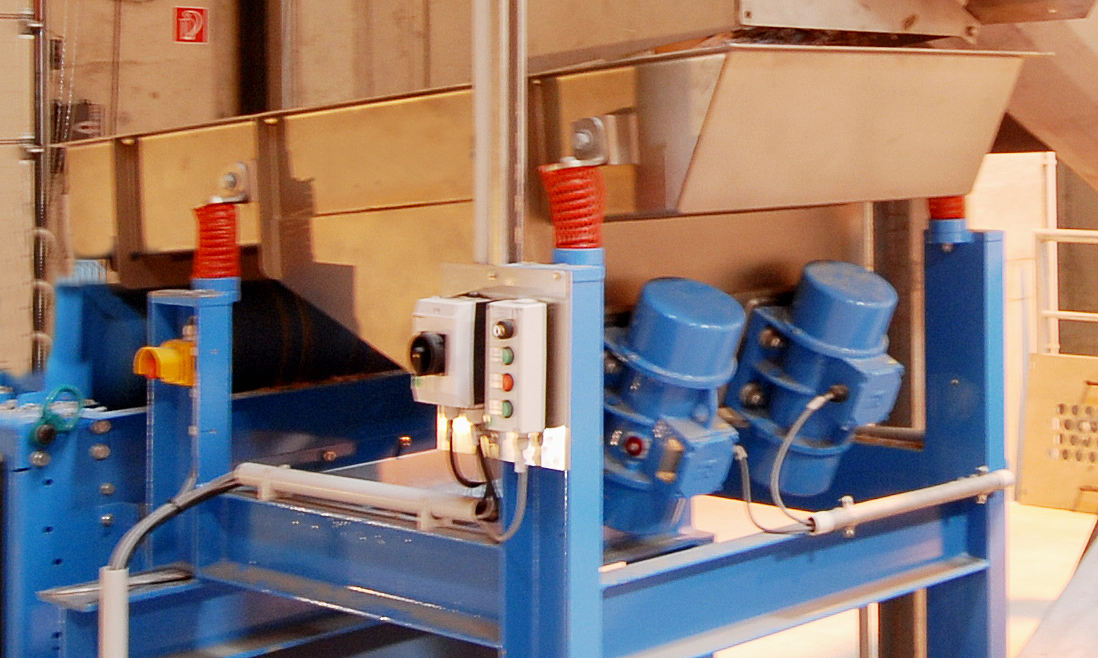

The MERI Vibrating Conveyor uses controlled vibration to move material along a tray or chute.

Vibration is generated by unbalanced motors, or mechanical excentre rotating weights. The Reject and Residual material is conveyed through a series of small jumps caused by oscillations.

Flow rate resp. conveying speed can be adjusted by amplitude and frequency of vibration (motor rpm).

Beside transportation of wet or dry bulk material the MERI Vibrating Conveyor is suitable to disaggregate material and generate an even uniform material flow, from spontaneous dumps / bulk loads like Crane- and Caterpillar buckets.

Features

The MERI Vibrating Conveyor offers several advanced technical features:

- Simple design > a trough, chute, or tray mounted on springs

- Variable vibration control > frequency, amplitude, inclination

- Handles dry, wet, sticky, and/or abrasive material

- Low maintenance > no belts or chains in contact with waste

- Durable liners (optional wear plates for abrasive fractions like sand or ash)

- Compact and enclosed options for dust control

Why to buy

- Handles large dumps / bulk loads of wet or dry materials

- Disaggregate bulk / dump material and generate an even, uniform material flow

- Uniform feeding > maximizes efficiency of downstream separation (Shredding screening etc.)

- Handles difficult waste (wet, dry sticky).

- Low operating cost > minimal wear parts

- Flexible installation → can work as a feeder, conveyor, or distributor. Compact

[bws_pdfprint_pagebreak]

Typical & Proven Process Applications

- Transport of pre-treated Reject and Residual Streams (fibrous sludge) within a mill / plant from different loading points as spontaneous dumps / bulk loads like Crane- and Caterpillar buckets.

- Generates unform material flow good for shredders and sorters

See the following Products as well

- Lion Shredder

- Finger Sorter

- Meri Belt Conveyor

- COMPAX screw compactor Series

- ECOMPAX and Minipress

- Sicon Pocket Conveyor SPCS

- RSP Sludge and Residual Press

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]