WALKING FLOOR and FEED CONVEYOR

Systems for Reject and Residuals

[bws_pdfprint_pagebreak]

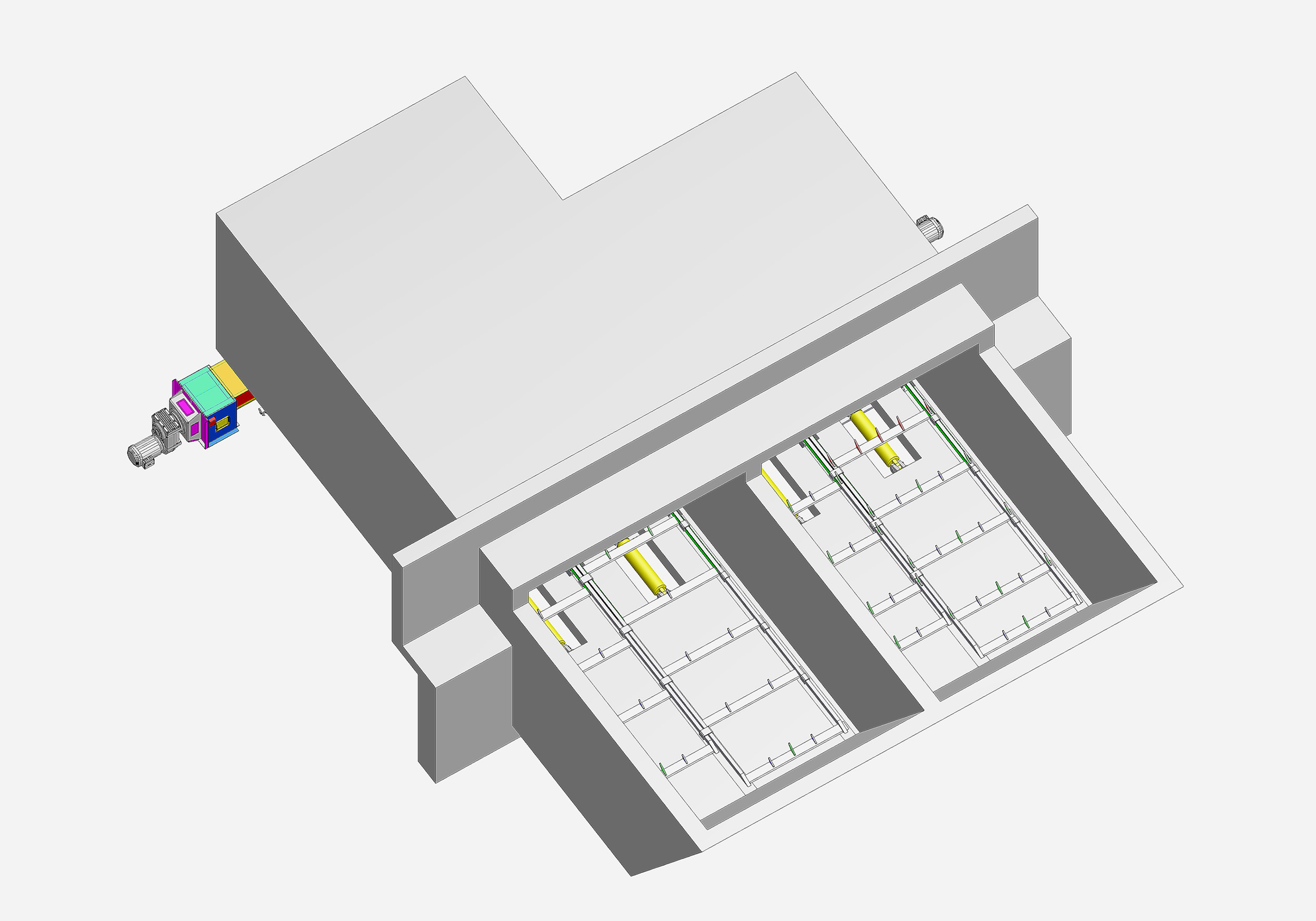

Walking Floor and Feed Conveyor

Systems for Reject and Residuals

Technology

A walking floor is a hydraulically driven conveyor system made of a series of slats (steel profiles) installed in the floor of a bunker, trailer, or container. The floor is divided into 2 or more (max 6) alternating groups of slats, which are moved by Hydraulic cylinders in a programmed sequence:

All slats move forward together > pushing the material in that direction.

Groups retract one by one → friction holds the material in place while only the slats move back, so this cycle repeats, so the bulk material “walks” steadily forward. The Alking Floor System system has no chains or belts in direct contact with waste — just slats moving under it.

An Alternative is a Screw Conveyor Floor

A screw conveyor floor is a bunker or pit floor equipped with parallel, heavy-duty screw conveyors installed across the full width. Waste or residuals are deposited into the bunker (via truck, grab crane, or conveyor). The screws rotate slowly and convey material toward a central discharge point (e.g., to a conveyor belt, shredder, or feeding line). Material is metered and evenly discharged, preventing surges or blockages downstream. Multiple screws operate together, driven by gear motors or hydraulic drives, with sequencing control to ensure smooth flow.

Features Walking Floor

The Walking Floor offers several advanced technical features:

- Hydraulic drive system with programmable logic (controls slat movement).

- Heavy-duty slats (aluminum as option for light fractions, steel for heavy or abrasive waste).

- Variable speed control > adjustable material feed rate.

- Reversible movement > can both load and unload material.

- Flush-mounted design > no gaps for material to fall through.

- Low headroom requirement > works in confined spaces.

- Handles irregular feedstocks > bulky, wet, or sticky waste.

- Safe operation > no tipping risk (important for trailers & transfer stations).Closed

Features of Screw Conveyor Floor

- Heavy-duty screws >→ designed for abrasive, bulky, or wet waste.

- Variable speed drive (VFD) > controls discharge rate precisely.

- Segmented screw arrangement > multiple screws working in parallel to cover wide bunker floors.

- Reversible operation > allows material flow direction changes when needed.

- Low installation height > fits in pits or shallow reception areas.

- Integration with overhead crane or direct truck tipping → easy filling.

Why to buy a Walking Floor

- Continuous, controlled flow > ideal for feeding Reject Systems especially shredders, boilers, or conveyors.

- High reliability > no belts or chains exposed to abrasive waste.

- Handles any material > from light plastics to heavy rubble.

- Flexible installation > in floors, silos, bunkers, or trailers.

- Safe & simple unloading > walking floor trailers don’t require tipping.

- Low maintenance > robust hydraulic system, replaceable slats.

- Scalable > available from small bunker floors to 100+ m² transfer station floors.

- Space-efficient > can replace push walls or front loaders for material handling

Typical & Proven Process

- Transport of pre-treated Reject and Residual Streams within a mill / plant from different loading points to different discharge points e.g. to the power plant

- Dust free transport in closed conveyor along every imaginable conveying track, including curves, rectangular turning, steep inclination.

- For the Screw Conveyor Floor reception of Truck Load with External Materials

See the following Products as well

- Lion Shredder

- Finger Sorter

- Meri Belt Conveyor

- COMPAX screw compactor Series

- ECOMPAX and Minipress

- MSC Meri Screw Conveyors

- RSP Sludge and Residual Press

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]