3D Laser Scanning for Upgrade Layout Engineering in Paper Mills

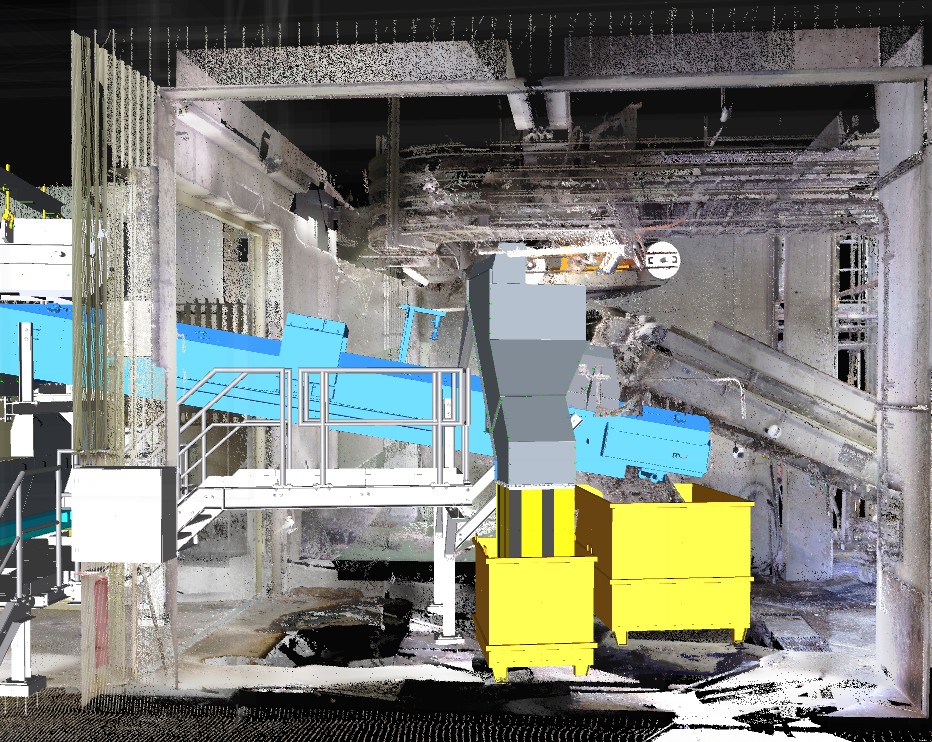

3D laser scanning captures the as-built conditions of an existing WSR subsystem, Material Handling- or Effluent Treatment- Plant in a paper mill

The capturing is executed with millimeter accuracy using Laser and LiDAR scanners, millions of data points are recorded to generate a point cloud model, which is then converted into a 3D environment for engineering use.

Key functionalities

- Accurate As-Built Documentation

- Captures existing tanks, piping, cable trays, structures, and confined spaces.

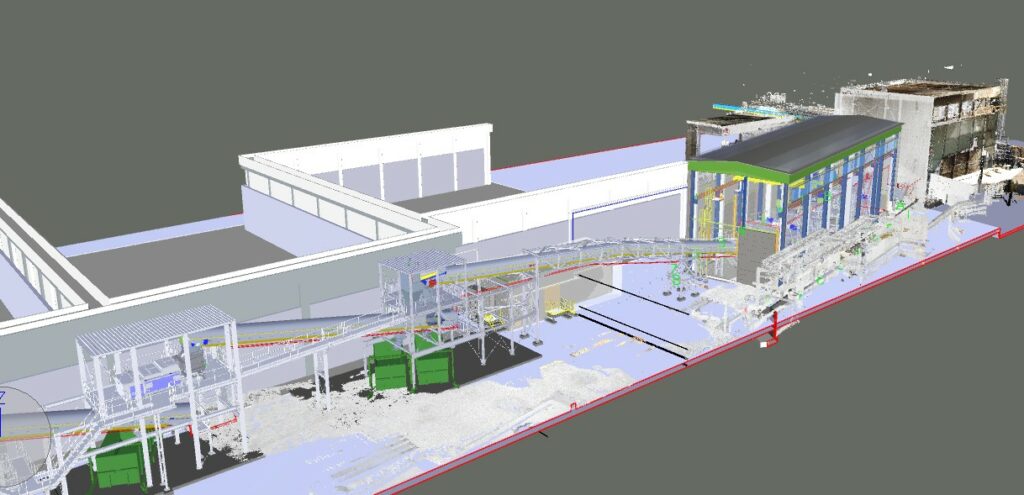

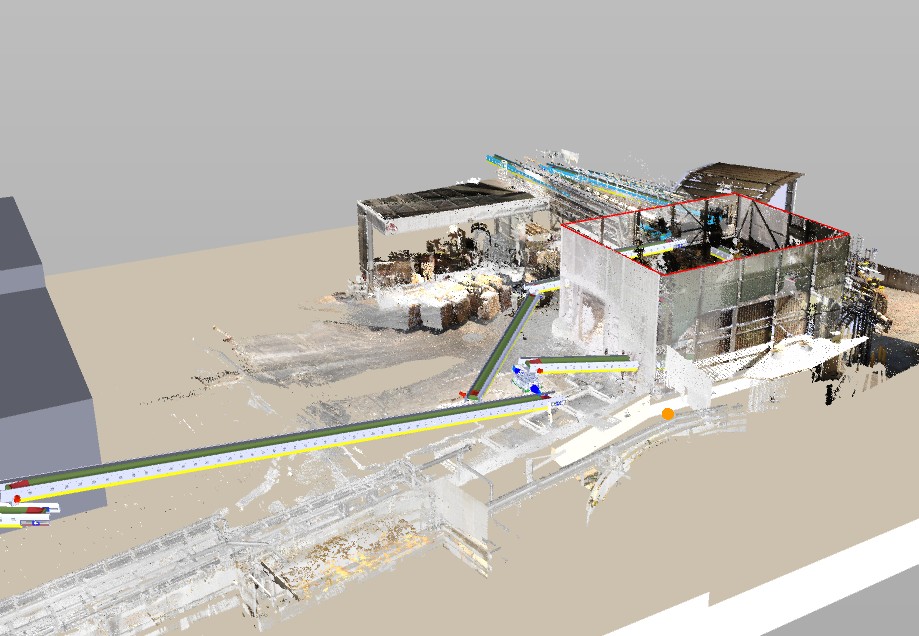

- Provides a digital twin of the mill for precise integration of new systems.

- Clash-Free Design for Brownfield Projects

- Engineers overlay new equipment (ETPs, scrubbers, sludge presses) in the scanned 3D model.

- Ensures new piping, cable routing, and foundations fit without site surprises.

- Complex Geometry Capture

- Ideal for irregular structures, congested pipe racks, or legacy areas with no drawings.

- Detects underground or overhead space constraints for routing.

- Remote Collaboration

- The 3D scan allows engineers, operators, and contractors to “walk through” the plant virtually, even from remote locations.

- Lifecycle Utility

- Beyond project execution, the scan becomes part of the digital asset for maintenance, inspection, and future upgrades

Advantages for Environmental Solutions & Upgrades

- High Accuracy → ±2–3 mm precision, far better than manual surveys.

- Full Coverage → Captures areas that are difficult or unsafe to measure manually.

- Rapid Data Collection → Large mill areas can be scanned in hours instead of weeks.

- Reliable Basis for 3D Modeling → Reduces dependency on outdated or missing 2D drawings.

Project Advantages

- Clash Detection Before Construction → Minimizes costly rework during installation.

- Optimized Layouts → Accurate space utilization for new tanks, pipelines, and racks.

- Reduced Downtime → Faster installation due to pre-fabricated piping/cables designed with real as-built dimensions.

- Lower CAPEX & OPEX Risks → Prevents “surprise” site modifications that escalate budgets.

- Safety Improvements → Limits manual site surveys in hazardous or high-access zones.

Typical Scope in Paper Mill Environmental Projects

- Scanning of existing ETP areas, sludge handling plants, pipe racks, utility corridors.

- Capture of congested mill interiors where new pipelines/cables must pass.

- Conversion of point cloud data into intelligent 3D CAD models (Invetor and NAVIS works)

- Integration of new system components and meri machines into the model.

- Clash analysis and layout optimization for:

- Piping systems (effluent, sludge, utilities).

- Cable trays and MCC connections.

- Structural modifications (platforms, supports, racks).

Typical Deliverables

- Point Cloud Database – raw and processed.

- As-Built 3D Model – showing all captured structures, piping, and equipment.

- 2D Extraction from 3D Scan –

- Updated GA drawings.

- Isometrics with exact dimensions.

- Cable routing layouts.

- Civil/structural interface drawings.

- Clash Reports – between existing and proposed systems.

- Digital Twin (Optional) – fully navigable model for operations & maintenance.