3D Layout Engineering for Environmental Solutions in Paper Mills

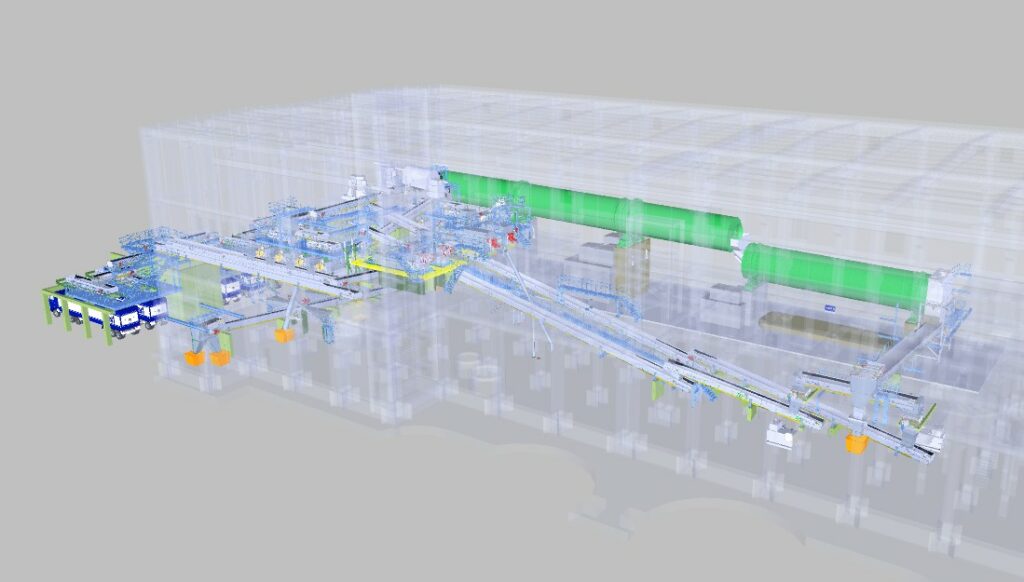

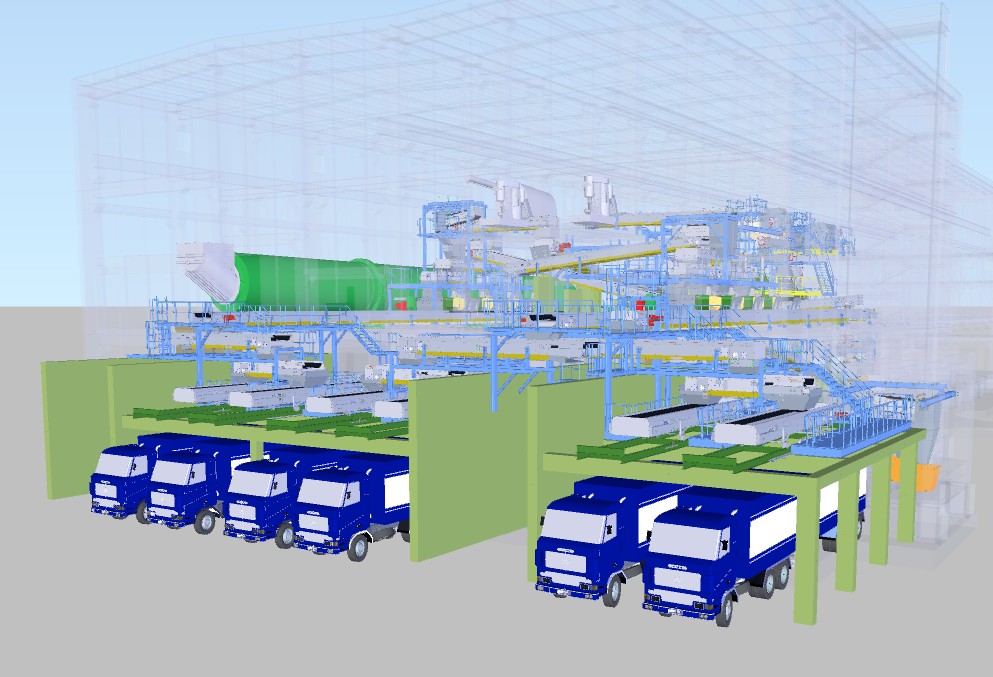

3D layout engineering uses digital plant modeling to visualize, design, and integrate new meri equipment in the environmental process facilities within a mill for green field plants or upgrades.

It ensures that piping, cabling, equipment, and structures fit together seamlessly before manufacturing and on site assembly begins.

Key functions

- Equipment Placement & Layout

- Positioning meri WSR, Material Handling ant ETP – equipment, auxiliaries tanks, reactors, pumps, blowers, gangways scaffolding and support steel works

- Optimizing space in tight and crowded brownfield sites.

- Piping & Cable Routing

- Designing process piping, water distribution, chemical lines, sludge pipelines, conveyor tracks, tank arangements in 3D.

- Planning cable trays, power lines, and instrumentation cabling alongside piping to avoid clashes.

- Clash Detection & Interference Checks

- Identifying conflicts between piping, ducts, cable trays, and structures before site execution.

- Reducing costly rework and delays.

- Construction & Maintenance Accessibility

- Designing layouts for safe operator access, maintenance clearance, lifting/hoisting paths.

- Ensuring compliance with safety norms.

- Integration with Existing Mill

- Overlaying environmental systems (ETPs, odor control, sludge handling) with existing production facilities.

- Minimizing downtime during retrofits or expansions.

Importance & Advantages

- Accuracy & Efficiency → Reduces errors by visualizing the complete system in 3D before fabrication.

- Cost Savings → Early clash detection avoids rework, which can save up to 10–15% of project cost.

- Time Optimization → Faster installation thanks to pre-fabrication drawings and exact routing data.

- Better Coordination → Facilitates collaboration across process, civil, piping, mechanical, electrical, and automation teams.

- Safety & Compliance → Ensures adherence to ergonomic standards, maintenance clearances, and environmental safety norms.

- Enhanced Communication → 3D models are intuitive for operators, managers, and regulators—improving project buy-in.

- Lifecycle Benefits → The model becomes a digital twin for operation, maintenance, and future upgrades.

Typical Scopes of 3D Layout Engineering in Paper Mill Environmental Projects

- 3D Modeling

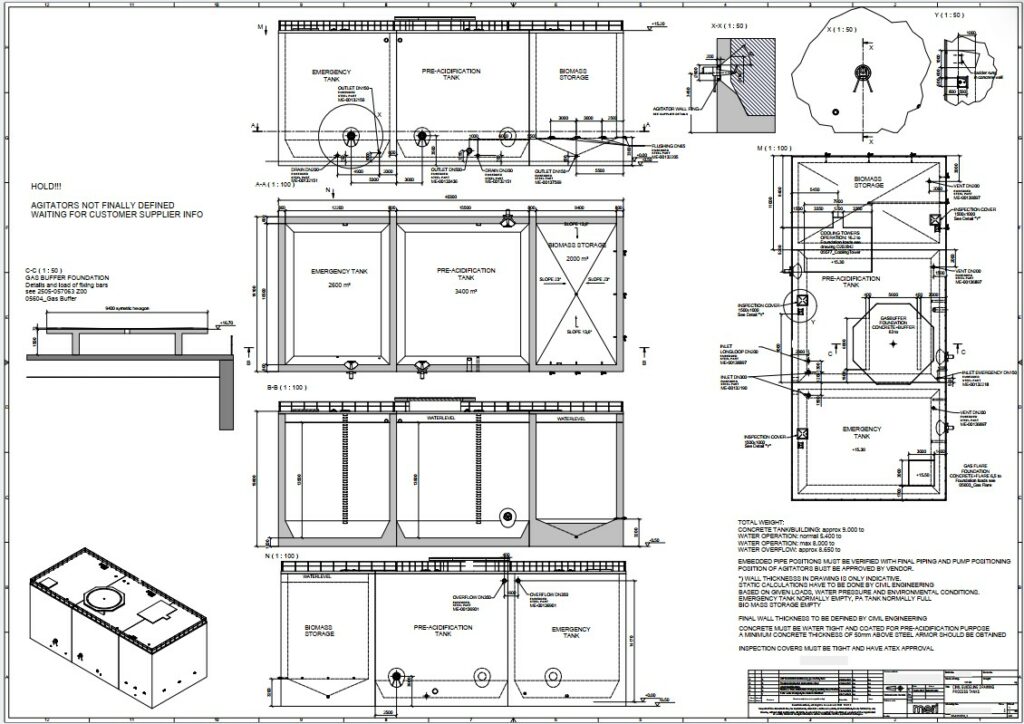

- ETP structures (clarifiers, aeration tanks, sludge thickeners, digesters).

- Sludge handling units (belt presses, centrifuges, dryers).

- Air emission systems (scrubbers, chimneys, ducts).

- Pipe racks, pump houses, and cable trays.

- Piping Engineering

- Process and utility piping (water, chemicals, sludge, steam, compressed air).

- Stress analysis and support design.

- Isometric drawings for fabrication.

- Electrical & Instrumentation

- Cable tray routing in 3D, avoiding clashes with piping.

- Equipment layouts for MCCs (Motor Control Centers).

- Instrument location and junction box layouts.

- Civil/Structural Coordination

- Concrete tank structures, foundations, steel pipe racks, platforms, walkways.

- Integration of equipment loads and access requirements.

Typical Documents & Deliverables

3D Deliverables

- Full 3D Plant Model (environmental system integrated into mill).

- Clash detection reports.

- NAVIS Works Walkthrough simulations for client/operator review.

- Bill of Materials (BOM) directly extracted from 3D model.

- Digital Twin (optional) for operations and maintenance.

2D Deliverables (extracted from 3D)

- General Arrangement (GA) Drawings.

- Equipment Layouts.

- Piping Isometrics with MTO (Material Take-Off).

- Cable Routing Layouts.

- Civil Interface Drawings (tank foundations, pipe rack footings).

- Sectional Drawings for installation guidance.