Elephant ET – Disc Thickener/ Filter

Multifunctional Disc Thickener

[bws_pdfprint_pagebreak]

Elephant ET – Disc Thickener/ Filter

Multifunctional Disc Thickener

Technology

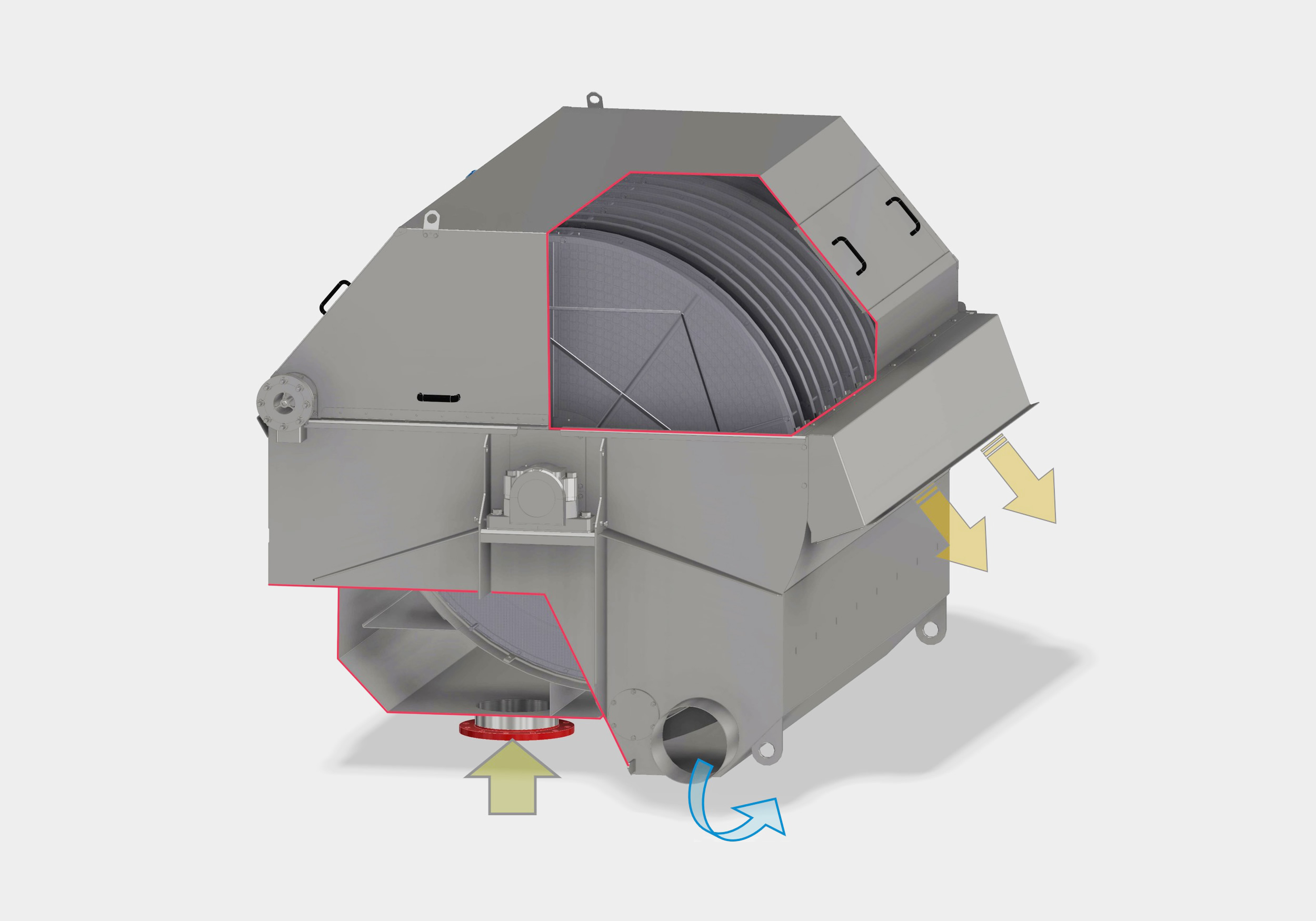

The Elephant Thickener / Filter consists of rotating disc pairs mounted on a shaft. Each disc is sealed against the machine vat by a highly resistant, long-life rubber sealing to ensure effective separation between feed and filtrate chamber. The feed suspension passes through the inlet chamber on the backside of the machine and distributes equally to all disc pairs. The water passes through the filter fabric mounted on the disc due to level difference between the feed and the filtrate side of it. The thickened solids are discharged on the frontside of the machine by the movement of the rotating discs. Backwash showers continuously clean the filter fabric. The filter fabrics are multilayer halve screen elements with mesh sizes of 100 to 800 µm. The filtrate water passing through the filter fabric is collected in a filtrate chamber and discharged from there through filtrate flanges. The water level in the machine vat is measured by a level transmitter and maintained by a level control valve in the filtrate pipe and by adaption of the rotation speed of the discs.

Features

- Completely enclosed machine design for clean and safe operation

- Effective filter fabric cleaning system

- Optional shower water protection system with cleaning brush and brush drive for backwashing with clarified water

- Feed flow and solids variation have only little effect on the discharge consistency of the solids and of the filtrate quality

- Multi-layer filter fabric technology for extended lifetime

- Several mesh sizes and wire technology available, depending on application

Why to buy

- Stable operation characteristics by advanced water level control

- Low OPEX by long life multilayer screens & disc sealing

- Easy operation

- Simple installation, no vacuum / drop-leg required

- Can be operated with and without flocculent addition

- Automatic Shower Water Protection System allows filter fabric cleaning with clarified/ filtered process water

[bws_pdfprint_pagebreak]

Typical & Proven Process Applications

- Liquid-solid separation for homogeneous and non-homogeneous suspensions

- Fiber recovery through thickening of suspensions as broke, stock and others

- Pre-Treatment of mill effluents and process flows loaded with heavy solids

- Soft washing & thickening in one machine by removal of fines and fillers

- Process Water Cleaning in Plastic Recycling (cold loop & hot loop)

See as well the following Products

- BlueDrain BDL – Belt Thickener

- COMPAX CFX-F 50,60 & 80

- MINIPRESS MPX 30, 40 & 50

- RSP- Sludge and Fiber Residual Screw Press RSP 650, 800 & 1150

- MSC- Spiral conveyors and related bunker- & container filling- & distribution systems

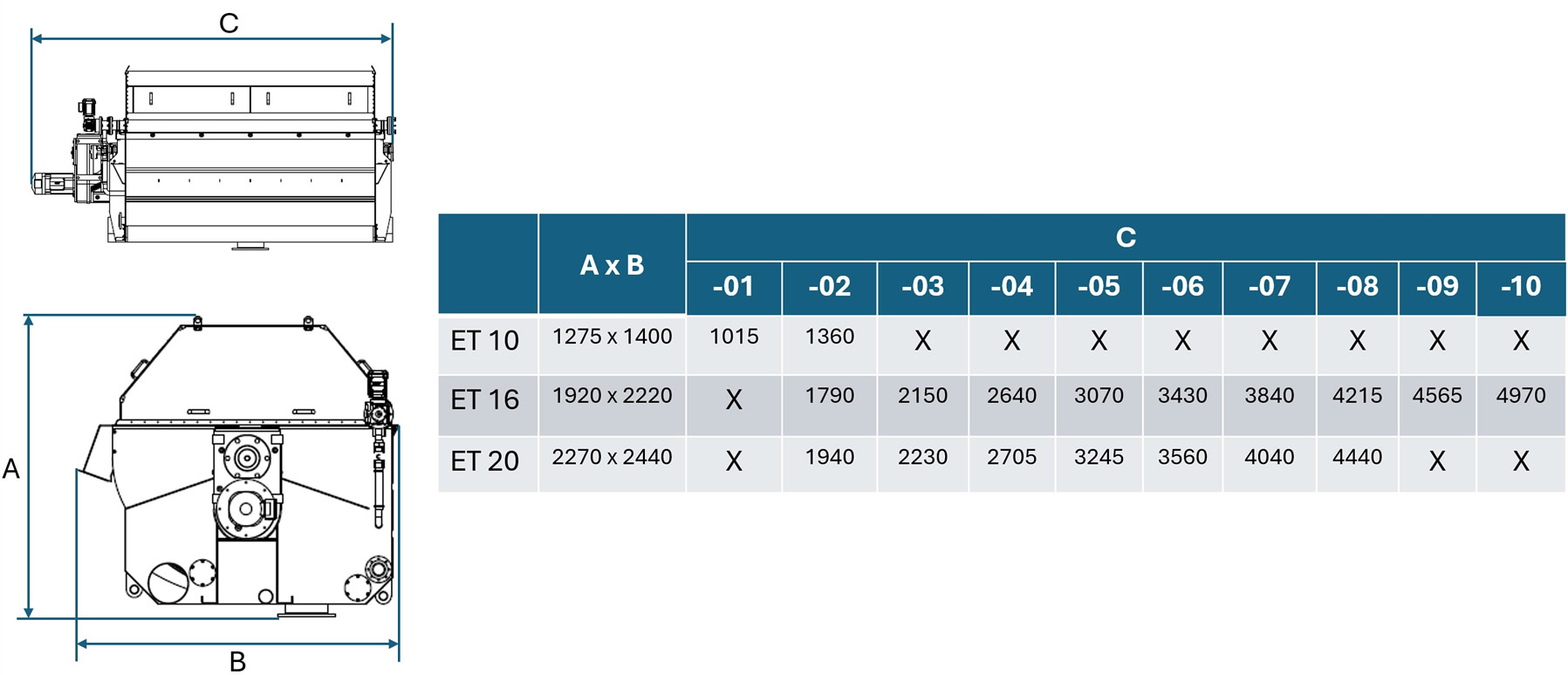

Specifications

[bws_pdfprint_pagebreak]

[bws_pdfprint display=’pdf’]